NHN Insulation Paper in Electric Vehicle Motors | Applications & Selection Guide

Application of NHN Insulation Paper in Electric Vehicle Motors As electric vehicles (EVs) continue to evolve toward ...

Application of NHN Insulation Paper in Electric Vehicle Motors

As electric vehicles (EVs) continue to evolve toward higher voltage platforms (400V / 800V), higher rotational speeds, and higher power density, traction motor insulation systems are subjected to high temperatures, high-frequency PWM voltage stress, strong vibration, and frequent start–stop cycles. NHN insulation paper (Nomex–Polyimide–Nomex composite) has become one of the key insulation materials used in high-performance EV motors due to its Class H and above thermal endurance and long-term stability.

1. Core Insulation Requirements for EV Motors

Compared with conventional industrial motors, EV traction motors impose much stricter requirements on insulation materials:

Long-term high-temperature operation (winding temperatures up to 160–180°C)

High dv/dt and voltage spikes caused by inverter-driven PWM control

Mechanical stress and vibration under high-speed operation

Frequent start–stop cycles and transient overload conditions

Demands for compact size, lightweight design, and long service life

Under these conditions, Class B or Class F insulation materials can no longer ensure reliable lifetime performance.

2. Main Application Areas of NHN in EV Motors

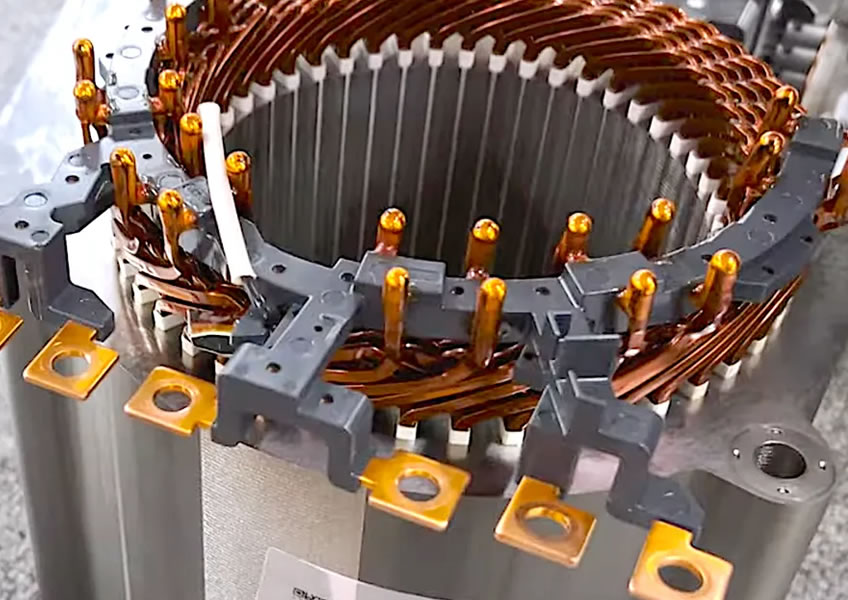

Stator Slot Insulation

Installed between the stator core and windings, where thermal and mechanical stresses are highest

NHN provides excellent thermal resistance and tear strength, effectively preventing insulation aging, damage, and electrical breakdown

Suitable for high-speed motors and high slot fill factor designs

Phase-to-Phase Insulation

Used to separate different phase windings

Under high dv/dt PWM environments, NHN significantly reduces the risk of phase-to-phase breakdown and partial discharge

Interlayer / Turn Insulation

Applied in compact, high power-density winding structures

Provides reliable electrical insulation in limited space, enhancing overall dielectric strength

End-Winding Insulation and Reinforcement

Reinforces and stabilizes end windings

Reduces vibration-induced fatigue and structural loosening during high-speed operation

3. Advantages of NHN over Other Insulation Papers in EV Motors

| Material | Thermal Class | Suitability for EV Motors |

|---|---|---|

| DMD | Class B / F | Entry-level or auxiliary applications |

| NMN | Class F / H | Mid-range EV motors |

| NHN | Class H and above | High-performance / high-voltage EV motors |

NHN demonstrates outstanding performance in thermal lifetime, vibration resistance, and high-frequency electrical stress tolerance, making it particularly suitable for 800V platforms and high-speed hairpin motors.

4. Selection Guidelines for NHN in EV Motors

Thermal Class Matching

EV traction motors are typically designed with Class H or higher insulation systems

NHN provides an ideal match for long-term thermal endurance requirements

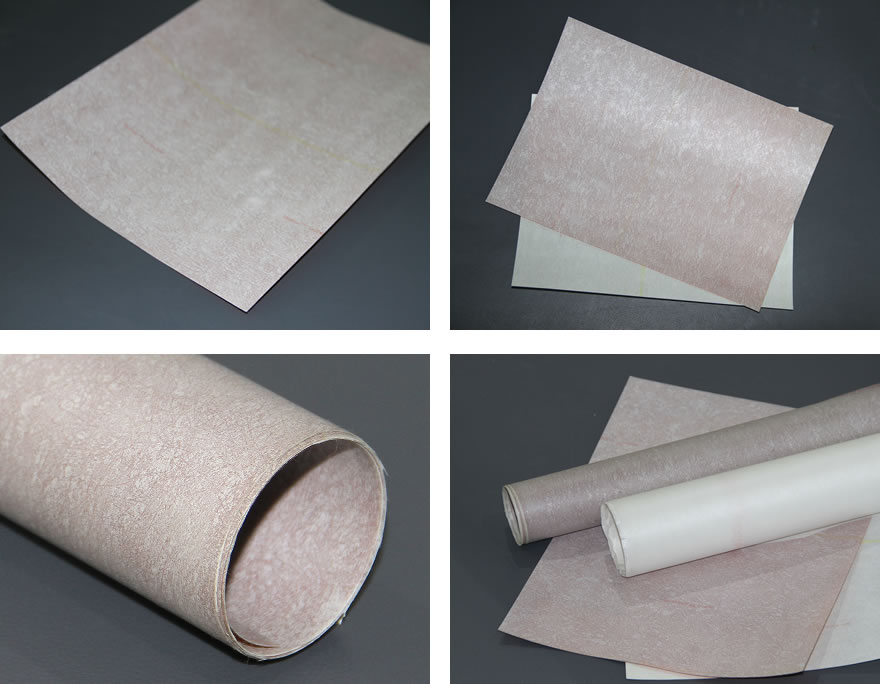

Typical Thickness Range

Slot insulation: 0.15 / 0.18 / 0.20 mm

Phase insulation: 0.18 / 0.20 / 0.25 mm

Final thickness selection should be based on slot geometry, voltage level, and slot fill factor.

Process Compatibility

Suitable for automatic slot paper insertion and high-speed winding processes

Compatible with VPI (Vacuum Pressure Impregnation) and various insulation resin systems

Well suited for mass production and automated motor manufacturing lines

5. Application Trends

Rapidly increasing adoption in 800V high-voltage EV platforms

Widely used in high-speed, high power-density hairpin motors

Gradually becoming a standard insulation solution for premium and performance EV models

6. Conclusion

The application of NHN insulation paper in electric vehicle motors is a technically justified response to high temperature, high voltage, high-frequency electrical stress, and strong vibration. Its use in critical areas such as stator slot insulation, phase insulation, and end-winding reinforcement significantly enhances motor safety, reliability, and service life, making NHN an essential insulation material for next-generation EV traction systems.

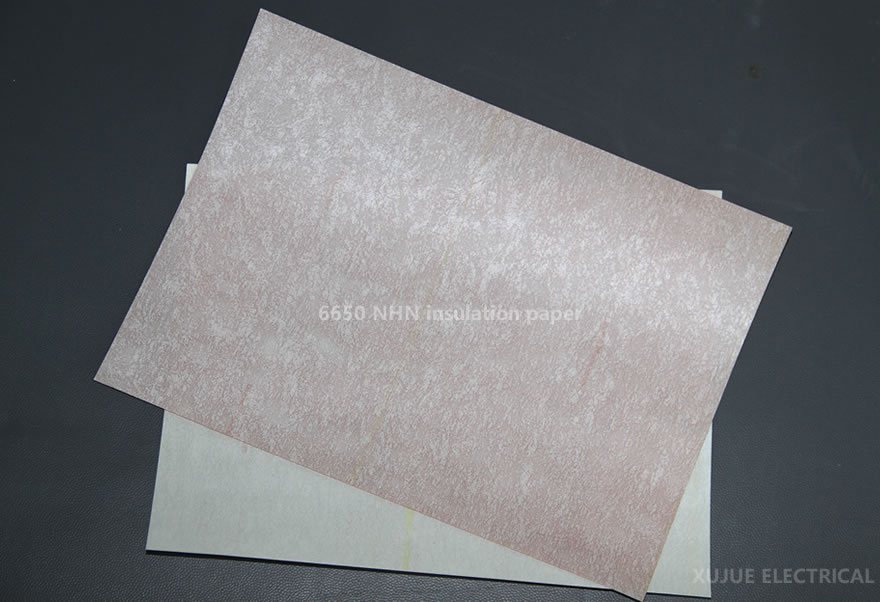

7. Manufacturer selection

The insulation material for motor NHN must be selected from the source manufacturer,

XUJUE ElECTRICAL is a professional manufacturer of high-quality electrical insulation materials with more than 65 years of manufacturing experience. The products have passed UL,RoHS,SGS,MSDS,CEMT testing and certification.

If you are looking for motor insulation paper, please contact Xujue Electrical and provide the product specifications, thickness and purpose you need, you can get detailed product information and quotation, and also send samples free of charge

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308

- 01-30 2026Wind Turbine Insulation Materials Selection Guide