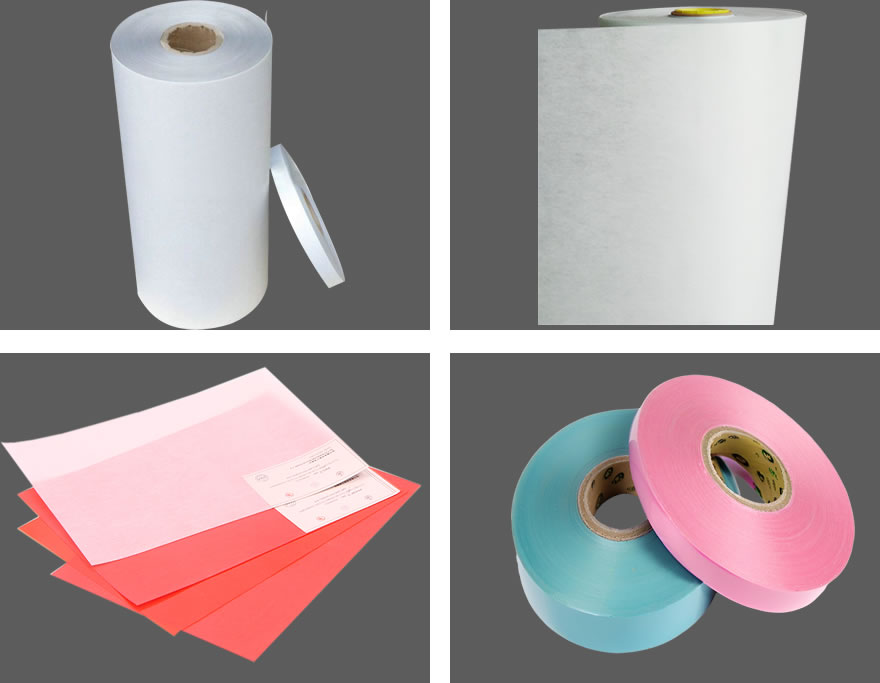

DMD Insulation Paper (DMD Paper)

Insulation class: B/F class (130°C/155 °C)

Color: Blue, green, white and pink

Width: 10-1000mm

Thickness: 0.15-0.4mm

Support customization

Leave us a message to get quotation and sample!

If you are attractive to our products, please send us a message and we will contact you as soon as we receive it.

Product Introduction

DMD insulation paper is a three-layer flexible composite insulating material consisting of a layer of polyester film sandwiched between two layers of non-woven polyester fabric and laminated with class F adhesive.It has good heat resistance, dielectric properties and mechanical properties and good impregnated properties.

Tape: ≥10mm Width: Maximum 1000mm*900mm

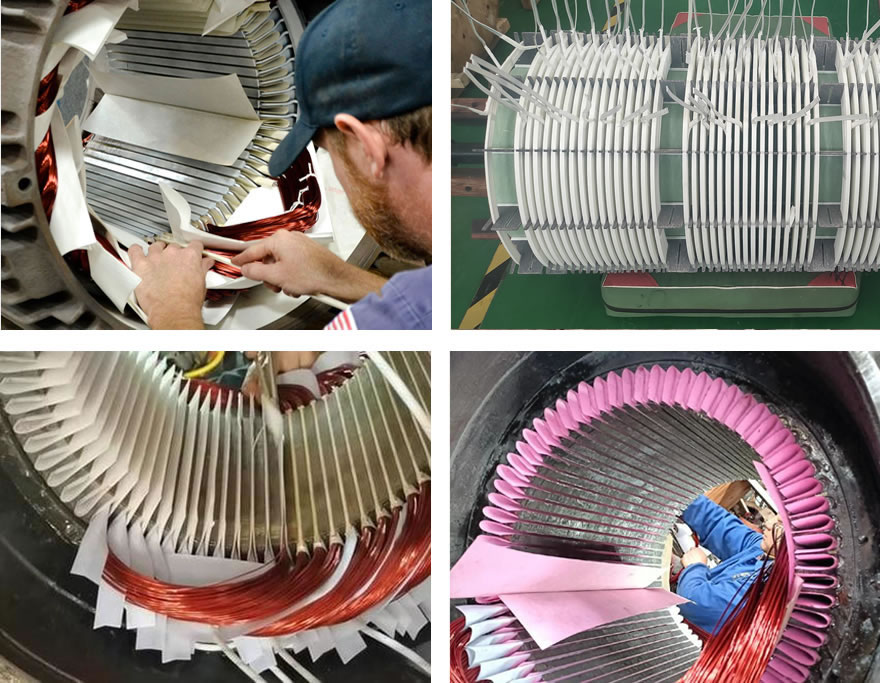

DMD Application

DMD Insulation Paper has been widely used in class F motors and transformers for slot insulation, interphase insulation and liner insulation.

DMD Insulation Paper Technical Data Sheet

| NO. | Item | Unit | Index | |||||||

| 1 | Nominal thickness | mm | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | ||

| 2 | Thickness tolerance | mm | ±0.020 | ±0.030 | ±0.030 | ±0.035 | ±0.040 | ±0.040 | ||

| 3 | Nominal weight and tolerance | g /m2 | 150±22 | 220±32 | 260±39 | 310±46 | 390±58 | 440±66 | ||

| 4 | Tensile strength | MD | No bend | N /10mm | ≥80 | ≥120 | ≥150 | ≥170 | ≥200 | ≥300 |

| Bending | ≥80 | ≥105 | ≥130 | ≥150 | ≥180 | ≥220 | ||||

| CD | No bend | ≥80 | ≥105 | ≥130 | ≥150 | ≥180 | ≥220 | |||

| Bending | ≥70 | ≥95 | ≥120 | ≥130 | ≥160 | ≥200 | ||||

| 5 | Elongation | MD | % | ≥10 | ≥5 | |||||

| CD | ≥15 | ≥5 | ||||||||

| 6 | Breakdown voltage | Normal | kV | ≥7.0 | ≥9.0 | ≥11.0 | ≥13.0 | ≥15.0 | ≥18.0 | |

| 155±2℃ | ≥6.0 | ≥8.0 | ≥10.0 | ≥12.0 | ≥14.0 | ≥17.0 | ||||

| 7 | Strength | MD | N | ≥20 | ||||||

| CD | ≥30 | |||||||||

| 8 | Normal adhesion | – | No delamination | |||||||

| 9 | Thermal adhesion (180±2℃ 10mim) |

– | No delamination, no foaming, no glue flow | |||||||

| 10 | Adhesion after moisture | – | No delamination | |||||||

| 11 | Long-term heat resistance index/ Temperature index (TI) |

℃ | ≥155 | |||||||

NOTE:The data reflected in the above tables are typical or average values only and just for your reference in practical application, which do not assume any responsibility for the use of the product or any legal liability arising therefrom.

Epoxy Prepreg DMD Paper(Class F)

Prepreg DMD paper is made of class F DMD composite material impregnated with modified epoxy resin after baking and semi-curing.With long shelf life at room temp, low precuring temp & time, excellent electrical insulation, bonding and heat-resistant properties.Epoxy resin can be cured quickly, with low molecular volatiles and low shrinkage. It can be firmly bonded to the surface of copper (aluminum) metal. In adition, it is compatible with most glues, resins and paints and suitable for layer insulation of copper foil or aluminium foil on low-tension coils of dry-type transformers as well as suitable for slot and turn-to-turn insulation of class F motors and electrical applicant.

Prepreg DMD Paper Technical Data Sheet

| No. | Item | Unit | Index | |||||

| 1 | Nominal thickness | mm | 0.16 | 0.18 | 0.2 | 0.23 | 0.25 | 0.4 |

| 2 | Tensile strength and longitudinal non-bending | N /10mm | ≥70 | ≥80 | ≥100 | ≥150 | ||

| 3 | Soluble resin content | g /m2 | 60±15 | |||||

| 4 | Volatile content | % | ≤1.5 | |||||

| 5 | Breakdown voltage | kV /mm | 6 | 7 | 8 | 9 | 10 | 16 |

| 6 | Tensile shear strength | Mpa | ≥3.0 | |||||

Dimension

| Thickness mm | Thickness tolerance mm | Standard width mm | Custom width mm | Quantitativeg/m2 | Quantitative toleranceg/m2 |

| 0.16 | ±0.030 | 1000 | 10~1450 | 180 | ±30 |

| 0.18 | ±0.030 | 1000 | 10~1450 | 200 | ±30 |

| 0.2 | ±0.035 | 1000 | 10~1450 | 220 | ±30 |

| 0.23 | ±0.035 | 1000 | 10~1450 | 250 | ±30 |

| 0.25 | ±0.035 | 1000 | 10~1450 | 280 | ±30 |

| 0.4 | ±0.035 | 1000 | 10~1450 | 490 | ±30 |

NOTE:The data reflected in the above tables are typical or average values only and just for your reference in practical application, which do not assume any responsibility for the use of the product or any legal liability arising therefrom.

Production workshop

Packed in rolls in cartons, stored at room temperature away from sunlight and fire, storage period 12 months.

FAQ

1.Where is your factory?

Our factory is in Xuchang city, Henan province, China.

2.Can I visit your factory?

Of course, welcome to our factory.

3.Can you send me samples to test?

Yes, we offer free samples to customers and they just need to pay the freight.

4.Do you have any certificates for your products?

Yes, we have UL certificate, SGS, ISO 9001: 2008 etc.

5.What ’s your payment terms?

Usually our payment terms is 30% paid by T / T in advance and the balance paid before shipment. This is negotiable.

6.What ’s your delivery time?

It depends on the product and order quantity. Usually the delivery time is within 7-15 working days after getting deposit.

7.What ’s your main product?

We supply all kinds of insulation materials used in electrical field and most of them used in transformers and motors.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778