To identify high-quality G10 Epoxy sheet products, consider the following aspects: Appearance: Smoothness: High-qua...

To identify high-quality G10 Epoxy sheet products, consider the following aspects:

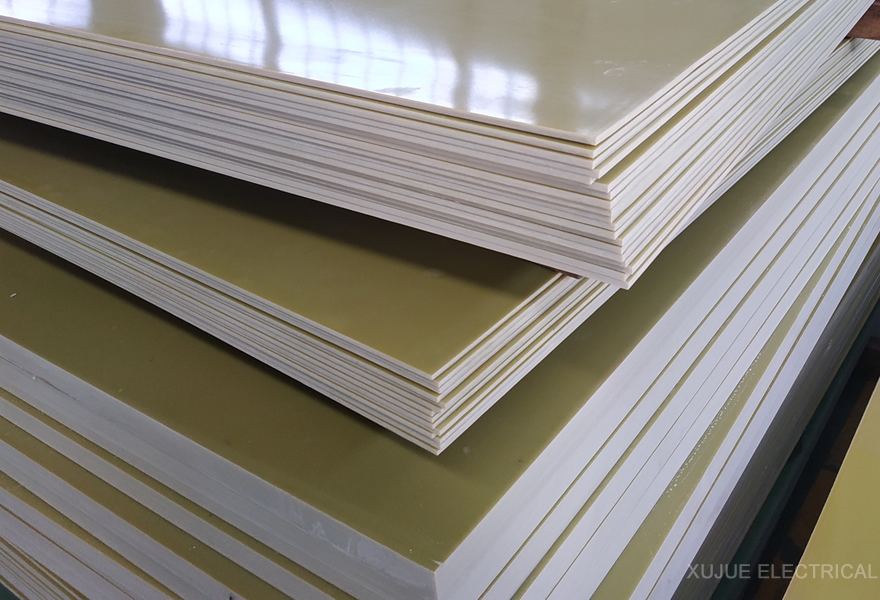

Smoothness: High-quality G10 Epoxy sheets have a smooth, flat surface, free from defects such as dents, bumps, and bubbles. Inferior boards may have uneven surfaces with noticeable pits, bumps, or bubbles, which not only affects appearance but may also impact performance in practical applications, such as causing uneven local electric fields.

Edge Neatness: High-quality products have neatly cut edges, straight edges, and no delamination or cracks in the cross-section. Inferior Epoxy sheets may have chipped edges, missing corners, or uneven cuts, which may cause dimensional mismatches or installation difficulties during processing and assembly.

Color Uniformity: G10 Epoxy sheets come in a variety of colors, such as the common aquamarine, yellow, black, and white. High-quality Epoxy sheets have a uniform, full color and pure hue; inferior products may have inconsistent color depth, color differences, or even discoloration and spots. This may be due to uneven mixing of raw materials or unstable production processes.

Density: High-quality G10 Epoxy sheets have a high density, which ensures good insulation performance and mechanical strength. The density difference can be initially judged by weighing or comparing the weight of products of the same size, but this method may not be very accurate and is for reference only.

Dimensional Stability: High-quality Epoxy sheets exhibit minimal dimensional change under different environmental conditions (such as changes in temperature and humidity), demonstrating good dimensional stability. The Epoxy sheet can be placed in different environments for a period of time, and its dimensional change measured. Significant dimensional changes indicate poor dimensional stability and may indicate an inferior product.

Flexibility: G10 Epoxy sheets possess a certain degree of flexibility without sacrificing strength. High-quality Epoxy sheets, after proper bending or application of pressure, can return to their original shape without breakage or cracking; while inferior Epoxy sheets may be too brittle and easily broken, or lack sufficient flexibility to meet the bending requirements of practical applications.

Insulation Resistance: As an insulating material, G10 Epoxy sheets should have high insulation resistance. Using a professional insulation resistance tester, the insulation resistance value of high-quality Epoxy sheets should meet relevant standards, ensuring good insulation performance and preventing current leakage in high-voltage environments; inferior Epoxy sheets may have lower insulation resistance, posing safety hazards.

Breakdown Voltage: Breakdown voltage is one of the important indicators for evaluating the electrical performance of Epoxy sheets. High-quality G10 Epoxy sheets have a high breakdown voltage, capable of withstanding high voltages without breakdown; inferior products may have a lower breakdown voltage, easily leading to breakdown during use and affecting the normal operation of equipment.

Dielectric Constant: The dielectric constant should meet design requirements to ensure the normal operation of the circuit. If the dielectric constant is unsuitable, it may affect the signal transmission, capacitance, and other performance aspects of the circuit. The dielectric constant can be measured using professional testing instruments to determine if the electrical performance of the Epoxy sheet meets the requirements.

Chemical Properties:

Corrosion Resistance: High-quality G10 Epoxy sheets resist corrosion from acids, alkalis, salts, and other chemicals, adapting to various usage environments.

Stability: Epoxy sheets with good chemical stability are less prone to aging and decomposition, exhibiting high reliability over long-term use. The chemical stability of the Epoxy sheet can be tested using accelerated aging tests and other methods, observing performance changes over a certain period. Small performance changes indicate good stability; conversely, large changes may indicate a substandard product.

Manufacturer Qualifications: Choosing G10 Epoxy sheets from well-known and reputable manufacturers ensures higher quality. Researching the manufacturer’s production scale, equipment, technical level, and quality management system helps assess their production capacity and product quality control capabilities.

Certification Status: High-quality G10 Epoxy sheets typically possess relevant certifications such as UL certification and SGS environmental testing. Check the product’s certification certificates to ensure that the product meets the relevant standards and requirements.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778