G11 Epoxy Sheet for Generator Slot Insulation

Application of G11 Epoxy Sheet in Generator Slot Insulation In large generators, motors, and high-voltage rotating e...

Application of G11 Epoxy Sheet in Generator Slot Insulation

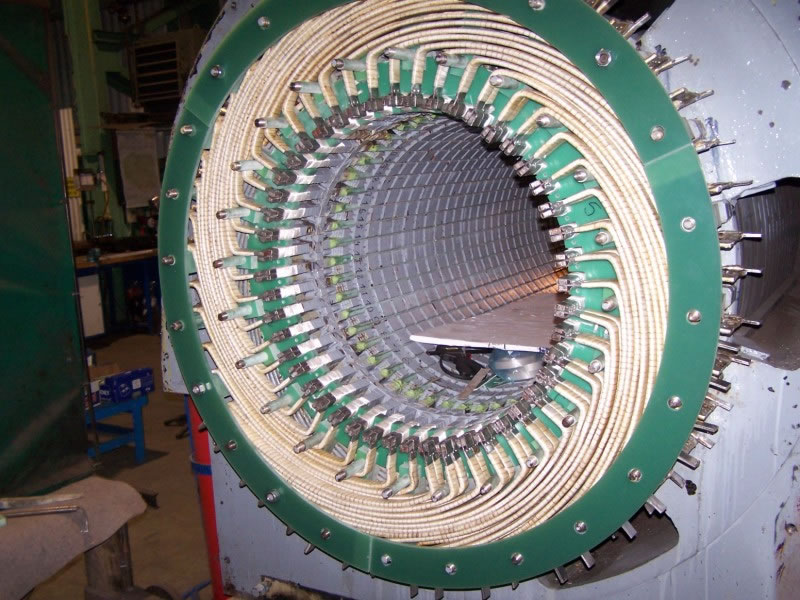

In large generators, motors, and high-voltage rotating electrical machines, stator slot insulation is a critical structure that ensures electrical safety and long-term operational reliability. Slot insulation materials must withstand high voltage, electromagnetic forces, and thermal stress, while maintaining stable performance under continuous vibration and elevated temperatures.

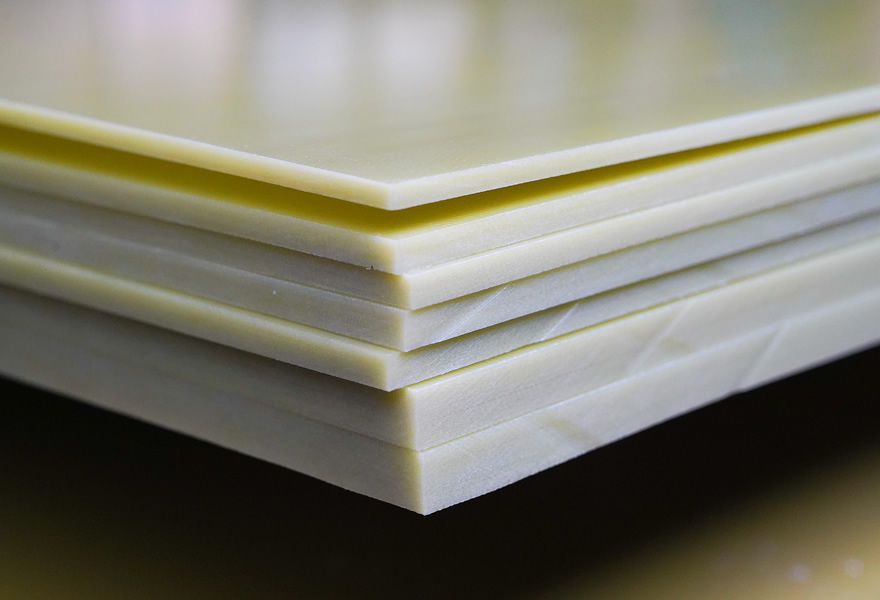

G11 epoxy fiberglass sheet, with its excellent high-temperature resistance and electrical insulation properties, has become one of the most widely used materials for generator slot insulation systems.

1. Key Requirements for Generator Slot Insulation Materials

Stator slot insulation in generators typically faces the following operating challenges:

High operating temperatures: Long-term service temperatures up to 155–180°C (Class F / Class H)

High electrical stress: Requires stable dielectric strength and resistance to partial discharge

Strong mechanical stress: Caused by coil insertion, electromagnetic forces, and continuous vibration

Harsh environments: Exposure to oil mist, humidity, dust, and thermal cycling

Therefore, slot insulation materials must provide:

High thermal endurance

Excellent electrical insulation performance

High mechanical strength and dimensional stability

2. Material Advantages of G11 Epoxy Sheet

G11 is a high-temperature-grade epoxy glass fiber laminate. Compared with G10 / FR4, it is more suitable for high-temperature rotating electrical machine insulation systems.

Outstanding High-Temperature Resistance

Thermal class: Class H (180°C)

Maintains mechanical strength and insulation performance under long-term high-temperature operation

Ideal for large synchronous generators, turbine generators, and hydro generators

Excellent Electrical Insulation Properties

High dielectric strength, effectively isolating stator core and windings

Low dielectric loss, reducing the risk of partial discharge

Minimal degradation of electrical performance in high-humidity environments

High Mechanical Strength and Vibration Resistance

Glass fiber–reinforced structure provides excellent bending and compressive strength

Withstands mechanical impact during coil insertion

Resistant to cracking and deformation during long-term operation

Good Dimensional Stability

Low coefficient of thermal expansion

Maintains shape under high temperatures and thermal cycling

Helps ensure long-term stability of stator slot structures

3.Typical Applications of G11 Epoxy Sheet in Generator Slot Insulation

G11 epoxy sheets are commonly machined into the following slot insulation components:

| Component | Function |

|---|---|

| Slot liners | Insulate the stator core from the windings |

| Slot spacers / shims | Provide mechanical support and secure windings |

| Slot mouth insulation parts | Enhance electrical safety at the slot opening |

| Custom insulating blocks | Distribute electromagnetic forces and reduce vibration |

G11 sheets can be CNC-machined to drawings, meeting different slot geometries and structural requirements.

4. Comparison of G11 with Other Common Slot Insulation Materials

| Material | Thermal Class | Typical Applications |

|---|---|---|

| G10 / FR4 | Class F (155°C) | Small and medium-size motors |

| G11 Epoxy Sheet | Class H (180°C) | Medium and large generators |

| DMD / NMN composites | Class F / H | Auxiliary and flexible insulation |

| Mica sheets | Class H and above | Ultra-high-voltage or special conditions |

In slot insulation positions requiring both high temperature resistance and high mechanical strength, G11 offers clear overall advantages.

5. Applicable Generator Types

G11 epoxy sheets are widely used in:

Thermal power generators

Hydroelectric generators

Wind power generators

Diesel generators

Large high-voltage motors

They are particularly suitable for applications requiring continuous operation and long maintenance intervals.

6. Conclusion: Why Choose G11 for Generator Slot Insulation?

For generators with high requirements for temperature rise control, electrical safety, and service life, G11 epoxy sheets are a proven and cost-effective solution for slot insulation systems.G11 achieves an excellent balance between thermal endurance, electrical insulation, and mechanical strength, making it a preferred material among generator and motor manufacturers worldwide.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308

- 01-30 2026Wind Turbine Insulation Materials Selection Guide