Composite Insulation Paper for Dry-Type Transformer Applications

Introduction Composite insulation paper is one of the most essential insulating materials used in dry-type transform...

Introduction

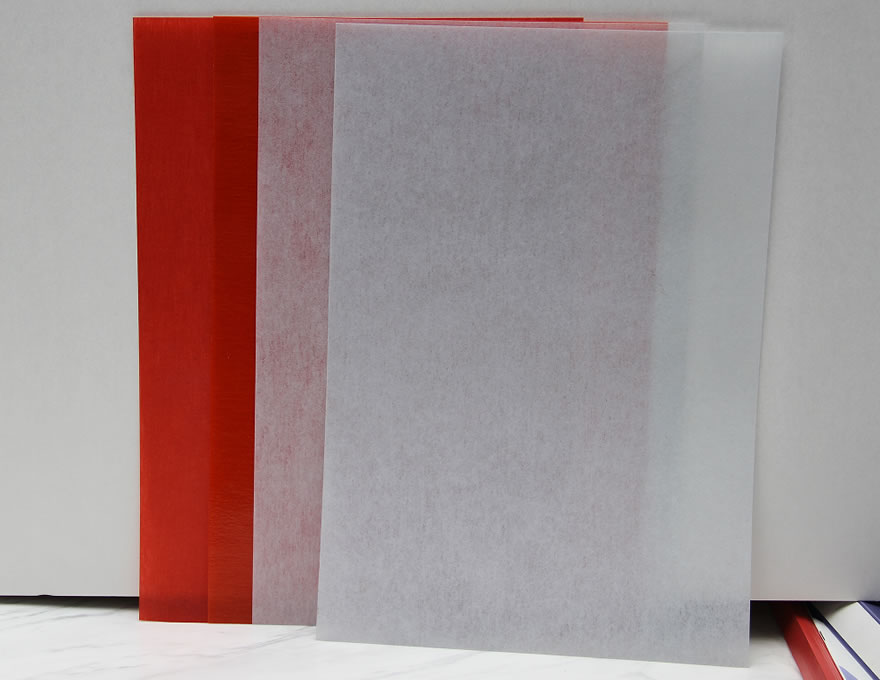

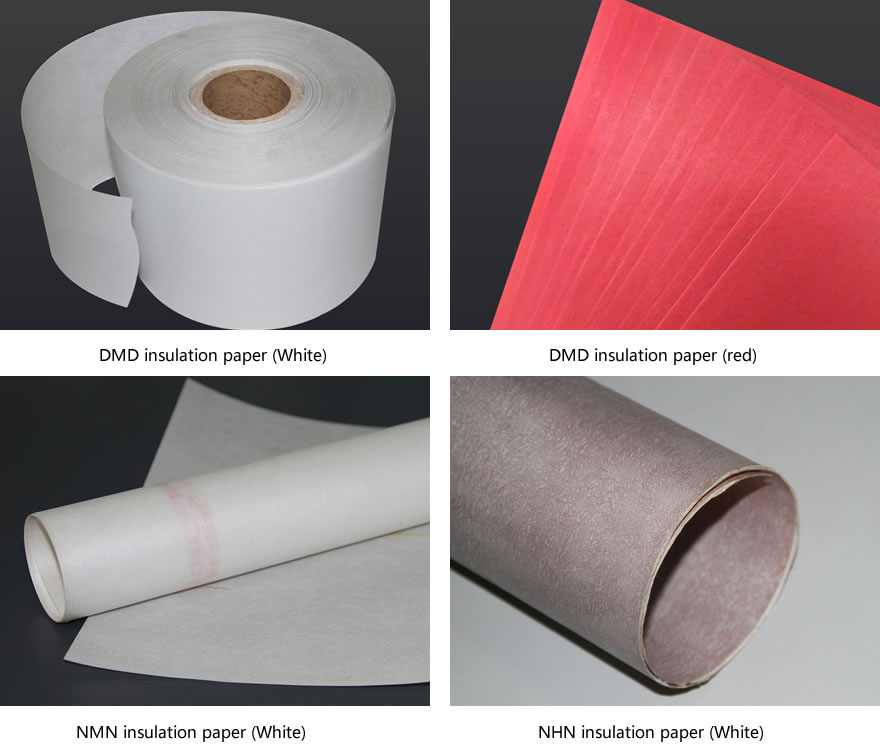

Composite insulation paper is one of the most essential insulating materials used in dry-type transformers. Common types include DMD (polyester non-woven + polyester film + polyester non-woven), NMN (Nomex + polyester film + Nomex), NHN (Nomex + polyimide film + Nomex), and DMDM.

These composite materials combine excellent dielectric strength, mechanical durability, and high thermal resistance, making them ideal for multiple insulation parts within dry-type transformer systems.

1. Coil Insulation

Composite insulation paper is widely used in transformer coil structures:

Interlayer insulation: Placed between winding layers to prevent turn-to-turn short circuits.

Phase insulation: Provides electrical separation between different phases of the winding.

End insulation: Protects coil ends from partial discharge and electric field concentration.

2. Slot and Wedge Insulation

In dry-type transformers with wound cores:

Slot insulation: NMN or DMD is used inside core slots to isolate windings from the magnetic core.

Slot wedges and liners: Strengthen mechanical stability and prevent coil movement or vibration damage.

3. Lead Wrapping and Terminal Protection

Composite insulation paper (especially DMD and NMN) is used for:

Lead wrapping and end covering, offering high flexibility and adhesion.

Thermal molding, ensuring tight and durable insulation around conductors.

4. Structural Spacers and Support Pads

In mechanical assembly, composite papers are laminated into spacers, pads, and barriers that provide both insulation and mechanical reinforcement between components.

5. Typical Materials and Thermal Classes

| Material Type | Structure | Thermal Class | Typical Application |

|---|---|---|---|

| DMD | Polyester non-woven + Polyester film + Polyester non-woven | Class B (130°C) | Interlayer and slot insulation |

| NMN | Nomex + Polyester film + Nomex | Class F (155°C) | Coil and slot insulation |

| NHN | Nomex + Polyimide film + Nomex | Class H (180°C) | High-temperature and special transformers |

| DMDM | Double-layer DMD | Class F (155°C) | Heavy insulation or high-voltage areas |

6. Key Advantages

Excellent thermal resistance (Class B–H)

High dielectric strength and electrical reliability

Superior mechanical toughness against bending and vibration

Good processability — easy to cut, punch, and form

Oil and chemical resistance, suitable for long-term operation

Conclusion

Composite insulation paper plays a critical role in dry-type transformer design, serving as interlayer, slot, and lead insulation. Its outstanding combination of thermal stability, electrical insulation, and mechanical strength ensures reliable transformer performance and extended service life.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308

- 01-30 2026Wind Turbine Insulation Materials Selection Guide

- 01-29 2026Flame-Retardant Epoxy Laminated sheet: Properties and Flame-Retardant Mechanisms

- 01-28 2026How to Identify High-Quality G10 Epoxy sheets