Technical Analysis of NHN Insulation Paper

High-Performance Composite Insulation Material NHN composite insulation material is manufactured by laminating Nomex...

High-Performance Composite Insulation Material

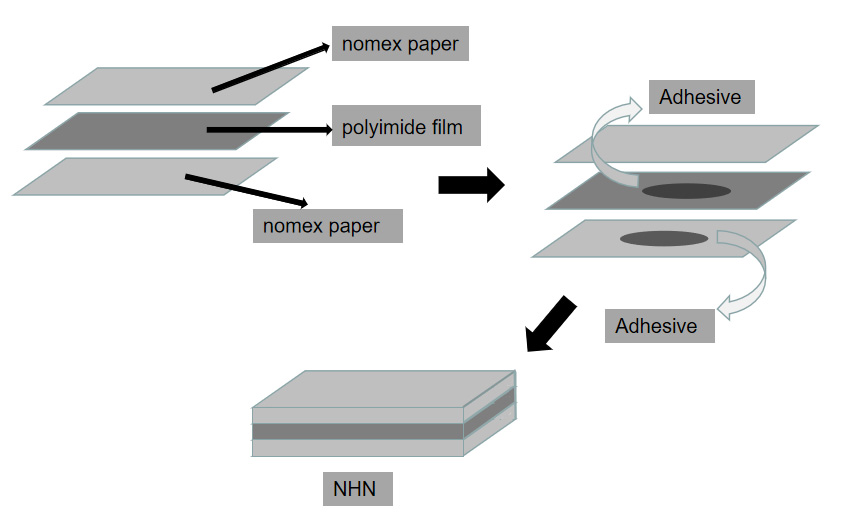

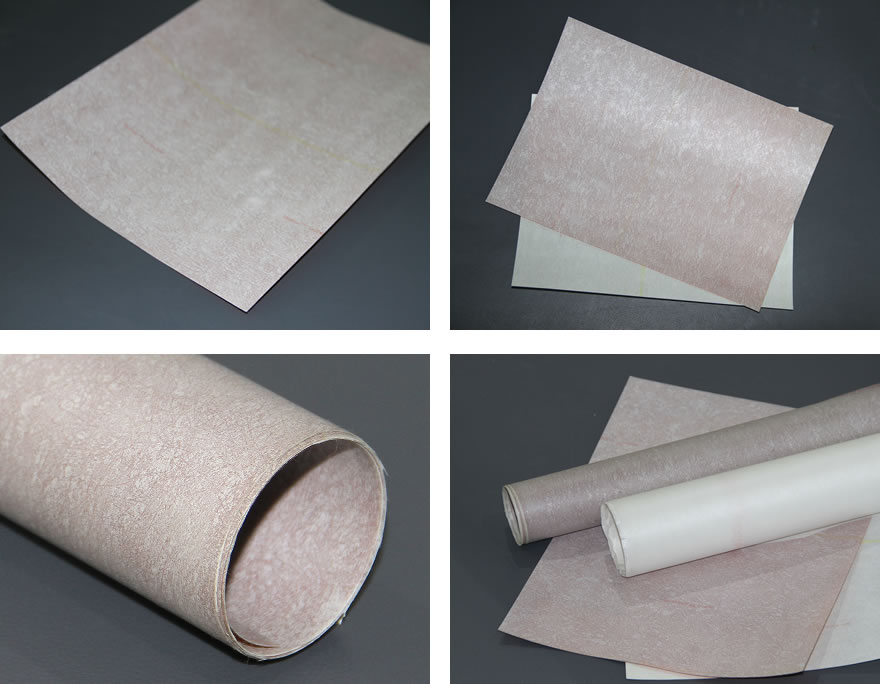

NHN composite insulation material is manufactured by laminating Nomex® meta-aramid paper on both sides of a central polyimide film (PI) using a high-temperature-resistant Class H adhesive system. Designed for long-term operation at Class H (180°C), NHN provides outstanding thermal endurance, mechanical strength, dielectric performance, dimensional stability, and chemical resistance. These properties make it one of the most widely used composite materials in modern 180°C insulation systems.

1. Key Applications in Electrical Power Equipment Insulation Systems

1.1 Critical Insulation for High-Efficiency Motors (Slot Insulation / Turn Insulation / Phase Insulation / Slot Liner)

NHN plays a central role in Class H motor insulation structures, offering the optimal combination of dielectric strength, tensile reinforcement, and thermal stability required in high-performance rotating machines.

Key advantages include:

High tear resistance: Edge tear strength ≥ 8 N, ensuring stability under centrifugal forces and vibration

Excellent thermal endurance: Continuous operating temperature up to 180°C

Smooth surface: Compatible with automated winding and automatic slot-insertion equipment

High compatibility with impregnating varnishes: Enhances overall system insulation, PD resistance, and dielectric stability

Typical applications:

New-energy vehicle traction motors

Servo motors and synchronous motors

High-speed spindle motors

Industrial VFD motors

In particular, for PMSM traction motors used in electric vehicles, NHN withstands combined stresses from high rotational speed, localized thermal buildup, and electromagnetic loading, significantly extending motor life and improving efficiency.

1.2 Layer and Phase Insulation for Dry-Type Transformers (Class H)

NHN serves as a layer-to-layer barrier, phase insulation, and lead wrapping material in dry-type transformers, leveraging its excellent dielectric and thermal stability.

Performance highlights:

Breakdown voltage ≥ 8 kV (0.25 mm)

Thermal class H (180°C)

Thin structure—0.14 to 0.47 mm for better winding space utilization

Compared with traditional presspaper or DMD, NHN allows for higher insulation levels within a limited coil window, enabling reduced transformer size and weight.

Typical applications include:

10–35 kV dry-type transformers

PV inverter transformers

High-frequency power transformers

Traction transformers

2. Applications in Industrial and Special-Purpose Equipment

2.1 Explosion-Proof Motors and Chemical Industry Drives

In petrochemical, mining, and other hazardous environments, insulation materials must provide both high thermal stability and exceptional safety performance.

NHN offers:

UL 94 V-0 flame retardancy

Resistance to oils, transformer oils, coolants, and solvents

Non-moisture-absorbing, non-delaminating, non-brittle structure

These properties help mitigate explosion risk and ensure long-term equipment reliability.

2.2 Rail Transit Traction Systems (High Vibration & High Temperature)

Traction motors and transformers used in high-speed rail must withstand:

Continuous vibration

High thermal loads

Long-duration operation

NHN’s laminated composite structure resists delamination under vibration and maintains dielectric integrity, making it suitable for 24/7 continuous operation in demanding rail systems.

2.3 Aerospace

Although ultra-high-temperature materials such as AHA and PPI composites are common in aerospace, NHN still plays a role in several aviation systems due to:

Lightweight structure

High dielectric strength

Stable thermal performance in motor hot zones

Applications include APU motors, aircraft HVAC motors, power converters, and certain guidance system components.

3. Applications in New Energy and Renewable Energy Systems

3.1 Electric Vehicles and High-Voltage Battery Systems

Traction Motors

NHN withstands frequent start/stop cycles, rapid temperature changes, and electromagnetic interference, ensuring long-term dielectric reliability.

Battery Packs

NHN is used in some high-voltage battery modules as:

Cell-to-cell isolation barriers

Electrical insulation layers

Thermal diffusion buffers

This helps prevent short circuits and limits thermal propagation.

3.2 Wind Power and Photovoltaic Systems

Wind turbine generators and PV inverter transformers face:

High humidity environments

Intense UV exposure

Dust, salt fog, and outdoor weathering

Long-duration full-load operation

NHN’s chemical inertness, moisture/heat aging resistance, and 180°C thermal class make it a highly dependable insulation solution for outdoor renewable-energy equipment.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers