Phenolic laminate classification Phenolic laminates are a very important industrial material, and there are many way...

Phenolic laminates are a very important industrial material, and there are many ways to classify them. They can be mainly divided from the following perspectives:

Phenolic laminates for electrical insulation: This is the most widely used category, mainly emphasizing excellent electrical insulation properties (such as dielectric strength, volume resistivity, surface resistivity) and certain mechanical properties. Commonly used insulating structural parts in electrical equipment.

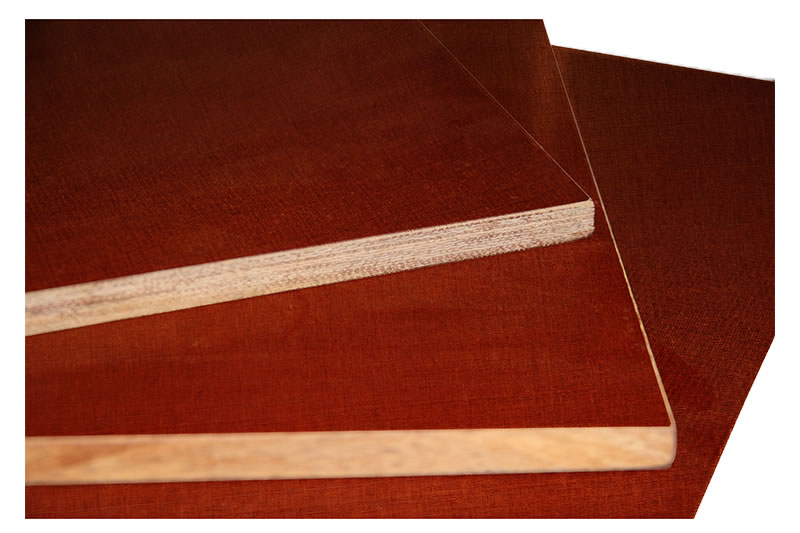

Phenolic Paper laminates: Insulating paper impregnated with phenolic resin is used as the base material. Low cost, good processability, good electrical properties, and medium mechanical strength. Typical models: PFCP 201, PFCP 202, PFCP 203 (old domestic models such as 3020, 3021, 3023); internationally commonly used NEMA grades such as XXX (economical), XX (standard), X (higher mechanical strength).

Phenolic Cotton Cloth laminate: Based on cotton cloth impregnated with phenolic resin.It has better mechanical strength (impact resistance, bending resistance), wear resistance and oil resistance than paper-based, good electrical properties, and is easy to machine.Typical models: PFCC 301, PFCC 302, PFCC 303 (old domestic models such as 3025, 3027); Internationally commonly used NEMA grades such as C (cotton cloth-based standard type), CE (cotton cloth-based, higher electrical properties).

Phenolic Glass Fiber Cloth laminate: Based on alkali-free glass fiber cloth impregnated with phenolic resin.It has the highest mechanical strength, dimensional stability, heat resistance, moisture resistance and excellent electrical properties.Suitable for electrical insulation and structural components requiring high reliability, high temperature or high strength. Typical models: PFGC 3240 (most common model in China), PFGC 3250 (high mechanical type); internationally commonly used NEMA grades such as G-10 (standard epoxy glass fiber, phenolic glass fiber is similar but slightly less heat-resistant), FR-4 (flame-retardant epoxy glass fiber, phenolic glass fiber flame retardancy is its inherent advantage). Note: Although FR-4 is mainly epoxy, phenolic resin itself has good flame retardancy, and its glass fiber board usually meets high flame retardancy requirements.

Phenolic Composite-based laminate: The base material is composited with two or more materials (such as paper + cloth, paper + glass fiber felt, etc.), aiming to balance cost, performance and processability.

Mechanical phenolic laminate: This type of board emphasizes high mechanical strength, wear resistance, oil resistance, impact resistance and dimensional stability, and electrical insulation performance is a secondary requirement. Usually made of cloth base or glass fiber cloth base.

Phenolic Cotton Cloth laminate (high mechanical type): Use cotton or synthetic fiber cloth (such as nylon cloth) with a specific weave, and the resin formula also focuses on mechanical properties. Excellent wear resistance, commonly used in gears, bearings, washers, etc. Typical model: PFCC 305 (domestic), international NEMA grade such as L (cotton cloth base, high mechanical/wear resistance).

Phenolic Glass Fiber Cloth laminate: (high mechanical type): Such as PFGC 3250, pursuing higher strength based on 3240.

Special wear-resistant plate: Solid lubricants such as molybdenum disulfide may be added.

Flame retardant type: All phenolic resins have a certain degree of flame retardancy (self-extinguishing when away from fire), but higher flame retardant grades (such as UL94 V-0) can be achieved by adding flame retardants (such as aluminum hydroxide, phosphorus series, nitrogen series) or using flame retardant substrates (such as glass fiber cloth). Most glass fiber cloth substrates (such as 3240) naturally meet high flame retardant requirements.

Arc-resistant type: Adding fillers such as trihydrated alumina, it has excellent ability to resist surface arc carbonization to form a conductive path, and is used for circuit breaker arc extinguishing pieces, etc.

Antistatic/conductive type: Adding conductive fillers (such as carbon black, metal powder, carbon fiber) makes it have the ability to dissipate static charge or conduct electricity.

High heat-resistant type: Using specially modified phenolic resins (such as xylene-modified phenolic) or substrates with better heat resistance (glass fiber cloth), it can work for a long time at higher temperatures.

High-frequency type: Optimizing resin formula and substrate, reducing dielectric constant and dielectric loss tangent, used for high-frequency circuit substrates, etc. (but usually not as good as epoxy or PTFE substrates).

Paper substrate: low cost, easy processing, good electrical properties, medium mechanical strength, and relatively low heat resistance.

Cotton cloth substrate: High mechanical strength (especially impact resistance and bending resistance), wear resistance, oil resistance, easy processing, good electrical properties, and lower moisture absorption than paper base.

Glass cloth substrate: Highest mechanical strength, best dimensional stability, highest heat resistance, excellent moisture resistance, excellent electrical properties, good wear resistance, but the tool wears quickly during processing.

Synthetic fiber cloth substrate (such as nylon cloth): Outstanding wear resistance and toughness, low friction coefficient, low water absorption, often used for wear-resistant parts such as bearings and gears.

Composite substrate: Mixed substrate, the performance is between its constituent materials.

3.Classification by heat resistance grade (refer to IEC 60085 or GB/T 11021)

Y grade (90°C): Generally not used for phenolic laminates.

A grade (105°C): Typical paper-based phenolic board (such as PFCP 201/XXX).

E-grade (120°C): Some paper-based or cloth-based phenolic boards (such as PFCP 203/X, PFCC 301/C).

B-grade (130°C): Most cotton cloth-based phenolic boards (such as PFCC 303/CE), some high-performance paper-based boards.

F-grade (155°C): Usually requires glass cloth (such as PFGC 3240), and some special modified cloth-based boards may also be achieved.

H-grade (180°C): Usually requires glass cloth-based phenolic boards with special modifications (such as xylene modification).

>200°C: Special high-temperature resistant phenolic or polyimide materials.

The most common classification and selection basis is “use + substrate”.

Electrical insulation:

General requirements, cost-sensitive: choose paper-based boards (such as PFCP 201/XXX, PFCP 202/XX).

Need better mechanical strength/oil resistance: choose cloth substrate (such as PFCC 301/C, PFCC 303/CE).

High reliability, high strength, high heat resistance, high flame retardancy, moisture resistance: choose glass cloth substrate (such as PFGC 3240).

Mechanical wear-resistant parts (gears, bearings, pads): choose cloth substrate with high mechanical strength (such as PFCC 305/L) or glass cloth substrate (such as PFGC 3250), or nylon cloth substrate.

Need special performance (such as high flame retardancy, arc resistance, anti-static, high frequency): need to find the corresponding special model.

Understanding the specific product model standards (such as China’s GB/T, international IEC, the United States NEMA LI 1 or ASTM D709) and the detailed technical parameter table provided by the supplier is the ultimate basis for accurate selection and application.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778