Identifying the quality of G10 epoxy sheet requires comprehensive judgment from multiple aspects such as appearance, ...

Identifying the quality of G10 epoxy sheet requires comprehensive judgment from multiple aspects such as appearance, physical properties, production process and certification qualifications. The following are specific detection methods and key indicators:

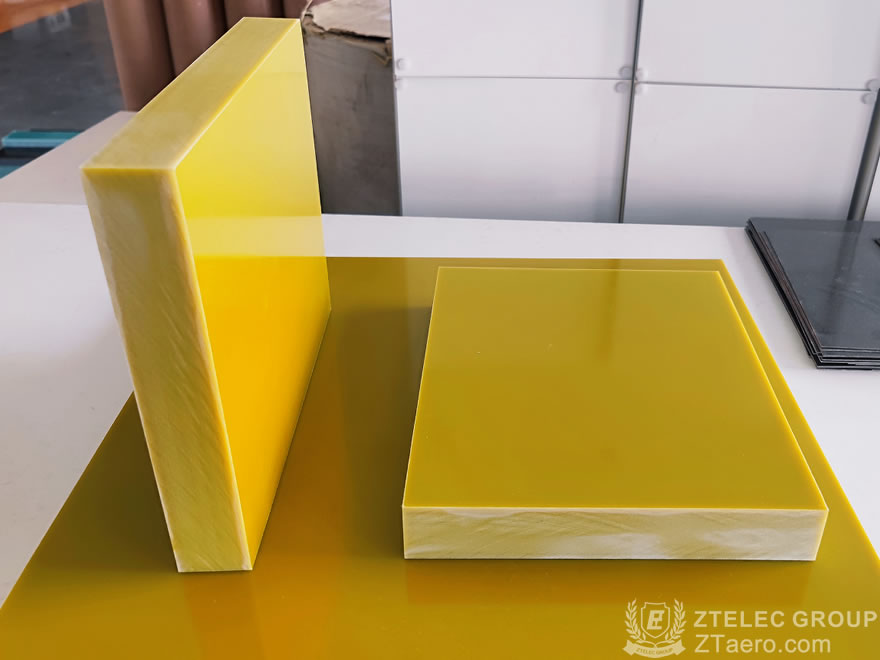

Surface flatness

High-quality G10: The surface is smooth and flat, without bumps, bubbles or obvious fiber exposure.

Poor-quality G10: There may be uneven resin distribution, rough fiber texture or local depression.

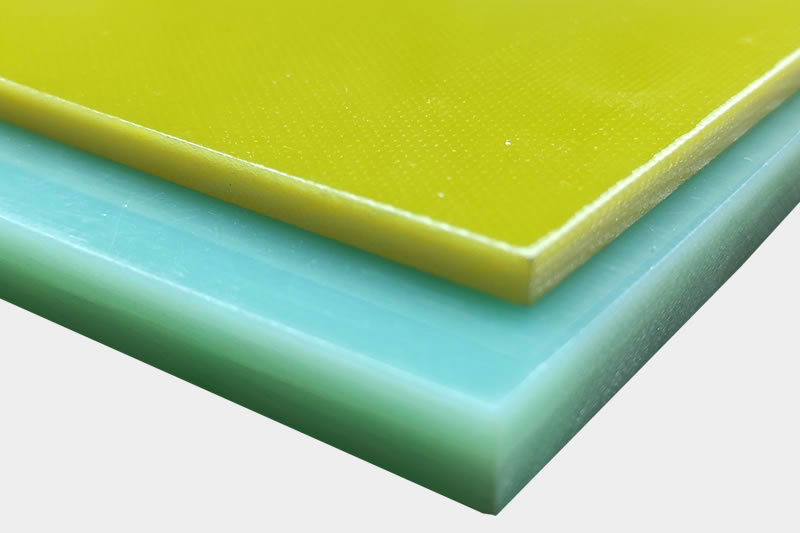

Color uniformity

High-quality G10: The color is uniform (whether black, green or other colors), without obvious color difference or spots.

Poor-quality G10: There may be uneven mixing of pigments, partial whitening or different depths.

Edges and cut surfaces

High-quality G10: The cut edges are neat, without delamination, burrs or broken edges; the cross section is dense, and the fiber and resin are tightly combined.

Poor-quality G10: The edges are delaminated and fluffy, and loose fibers or voids can be seen in the cross section.

Foreign Matter and Impurities

High-quality G10: No visible impurities (such as dust, metal debris).

Poor-quality G10: Impurities may be mixed in, reducing insulation and mechanical strength.

(Simple test method, no professional equipment required)

Hardness and Wear Resistance

Lightly scratch the surface with a key or a hard metal object. High-quality G10 should have no obvious scratches, while inferior products are easy to leave marks.

Bending Strength

Hold the two ends of the plate and bend slowly. High-quality G10 has good toughness and can rebound after slight bending; inferior products may be brittle and easy to break.

Density and Weight

Under the same size, high-quality G10 has a high glass fiber content (usually 60%-70%) and a high density (about 1.8-2.0 g/cm³), and feels heavy; inferior products may cut corners and be light in weight.

High temperature resistance

Bake the edge with a lighter (pay attention to safety). High-quality G10 will not deform or smoke in a short time. Inferior products may soften quickly and release pungent odors.

Mechanical properties

Tensile strength: High-quality G10 should be ≥350 MPa

Bending strength: High-quality G10 should be ≥400 MPa

Compressive strength: High-quality G10 should be ≥500 MPa

Electrical properties

Dielectric strength: ≥20 kV/mm (when the thickness is 3mm)

Volume resistivity: ≥1×10¹² Ω·cm

Chemical resistance

High-quality G10 should be resistant to common solvents (such as alcohol and motor oil) and should not swell or discolor after immersion for 24 hours.

Fourth, production process and certification

Raw material traceability

High-quality G10 uses alkali-free glass fiber (E-glass) and high-purity epoxy resin, and inferior products may be mixed with recycled materials.

Process standard

High-quality products use high-temperature and high-pressure lamination technology, and inferior products may simplify the process (such as room temperature curing), resulting in substandard performance.

Check whether it has passed authoritative certification:

UL certification (such as UL 94 V-0 flame retardant grade)

RoHS/REACH (environmentally friendly and non-toxic)

ISO 9001 quality management system

Request a test report: Require the provision of mechanical and electrical performance data tested by a third party.

Small sample test: First purchase a small batch of samples and conduct actual application tests (such as cutting, drilling, and load tests).

Beware of low price traps: The cost of G10 is significantly affected by the price of glass fiber and epoxy resin, and the market price is 20% lower than the industry average price, so be cautious.

Through the above methods, the quality of G10 epoxy sheet can be effectively distinguished to ensure that it meets the high performance requirements of scenarios such as industrial design, electronic insulation or tool manufacturing.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778