G10 Epoxy Glass Fiber Sheet Mechanical Strength and Applications

Mechanical Properties of G10 Epoxy Glass Fiber Laminate Product Introduction G10 epoxy glass fiber laminate is a co...

Mechanical Properties of G10 Epoxy Glass Fiber Laminate

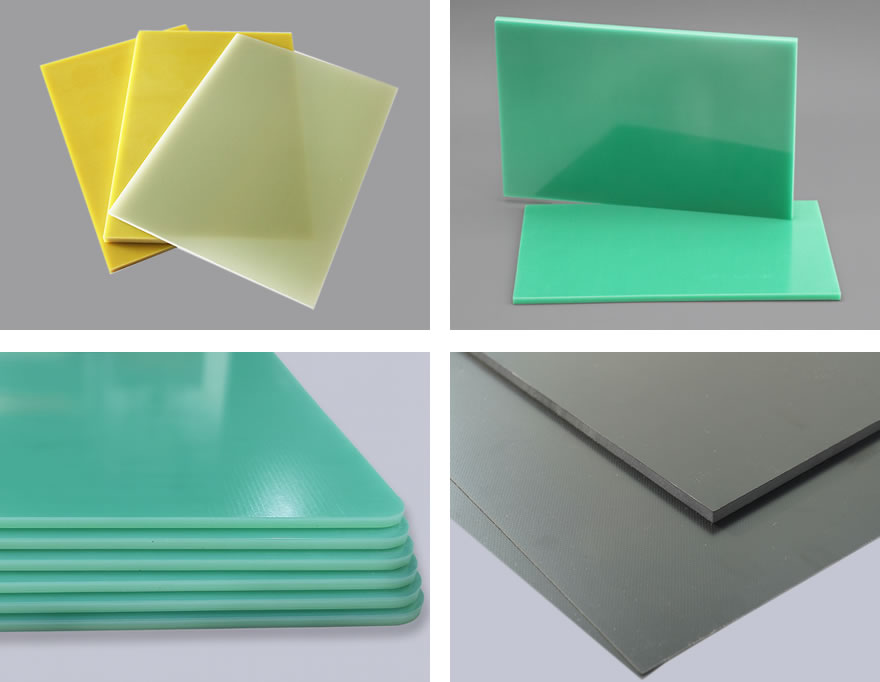

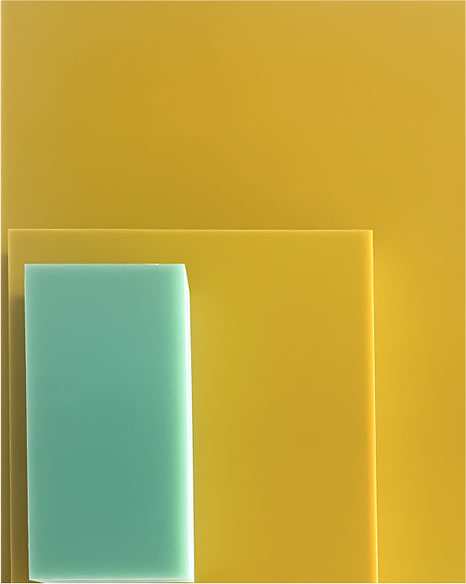

Product Introduction

G10 epoxy glass fiber laminate is a composite material made of electrical-grade glass cloth impregnated with epoxy resin, cured under high temperature and high pressure.

This structure provides high mechanical strength, dimensional stability, low moisture absorption, and excellent electrical insulation.

Typical Mechanical Properties (at Room Temperature)

| Property | Unit | Typical Value (G10) | Description |

|---|---|---|---|

| Density | g/cm³ | 1.80 – 1.90 | Lightweight structural material |

| Tensile Strength | MPa | 340 – 480 | Maximum tensile load before failure |

| Flexural Strength | MPa | 400 – 500 | Resistance to bending deformation |

| Compressive Strength | MPa | 350 – 450 | Resistance to compression loading |

| Shear Strength | MPa | 150 – 180 | Interlaminar bonding strength |

| Impact Strength (Izod) | kJ/m² | 10 – 15 | Energy absorbed before fracture |

| Flexural Modulus | GPa | 16 – 20 | Stiffness under bending load |

| Poisson’s Ratio | — | 0.12 – 0.17 | Ratio of lateral strain to axial strain |

| Water Absorption (24h @23°C) | % | ≤ 0.10 | Indicates dimensional stability |

| Continuous Operating Temperature | °C | 130 – 140 | Recommended long-term service temperature |

| Heat Deflection Temperature | °C | 150 – 180 | Short-term heat resistance |

| Volume Resistivity | Ω·cm | ≥ 1×10¹³ | Electrical insulation through the bulk |

| Dielectric Strength | kV/mm | ≥ 19 | Breakdown voltage per thickness |

| Surface Resistivity | Ω | ≥ 1×10¹² | Surface insulation capability |

| Flammability Rating | — | HB (G10) / V0 (FR4) | Fire resistance classification (UL94) |

| Strength Retention after Moisture | % | ≥ 95 | Strength stability under humidity exposure |

Test Standards Reference

| Test Item | International Standard (ASTM / IEC) | Chinese Standard (GB/T) |

|---|---|---|

| Tensile Strength | ASTM D638 | GB/T 1447 |

| Flexural Strength | ASTM D790 | GB/T 9341 |

| Compressive Strength | ASTM D695 | GB/T 1041 |

| Shear Strength | ASTM D2344 | GB/T 1450 |

| Water Absorption | ASTM D570 | GB/T 1034 |

| Dielectric Strength | ASTM D149 / D257 | GB/T 1408 |

Stability and Performance Advantages

Thermal stability: Minimal strength loss between −40°C and 130°C.

Low moisture sensitivity: Strength decreases less than 5% after water absorption.

High interlaminar adhesion: Prevents delamination under load.

Excellent creep resistance: Suitable for long-term load-bearing structures.

Comparison with Other Materials

| Material | Flexural Strength (MPa) | Density (g/cm³) | Remarks |

|---|---|---|---|

| G10 | 400–500 | 1.8–1.9 | High strength, insulation, machinable |

| FR4 | 350–450 | 1.85 | Flame-retardant version of G10 |

| Aluminum 6061 | ≈300 | 2.7 | Conductive, heavier |

| POM (Acetal) | ≈80 | 1.42 | Easy to machine, low strength |

| PEEK | 150–200 | 1.3 | Excellent but very costly |

Conclusion:

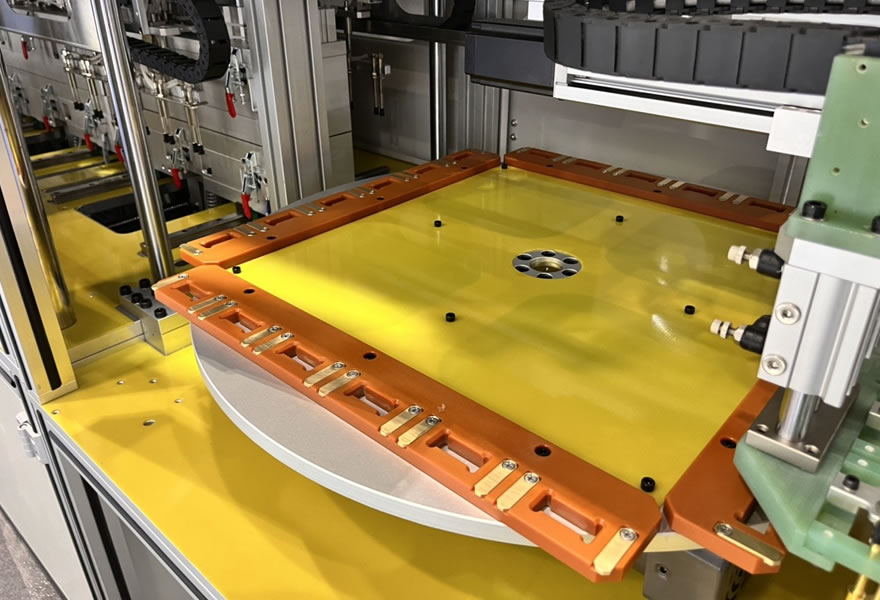

G10 offers metal-like mechanical strength combined with electrical insulation and corrosion resistance, making it an ideal choice for mechanical structures, electrical insulation components, and automation systems.

Machining & Handling Recommendations

Suitable for CNC milling, drilling, engraving, and laser cutting.

Use carbide or diamond-coated tools to prevent wear.

Control dust emissions (fiberglass dust is irritating to skin and lungs).

Store in dry, cool conditions, avoid prolonged exposure to sunlight or moisture.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers