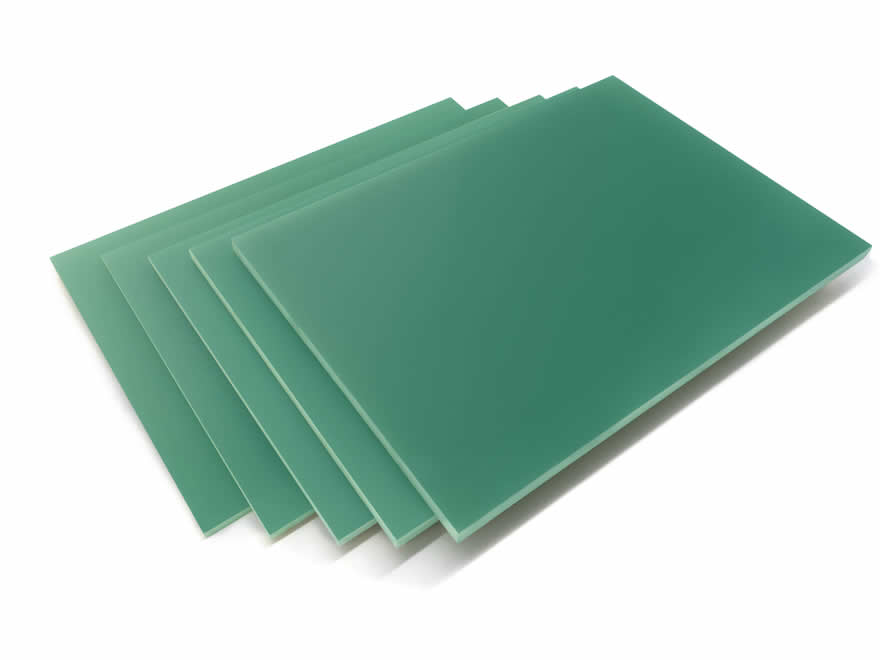

FR4 is the grade name of the most commonly used epoxy glass fiber laminate in the electronics industry. It is not on...

FR4 is the grade name of the most commonly used epoxy glass fiber laminate in the electronics industry. It is not only the core substrate of printed circuit boards (PCBs), but also used for other insulating structural parts. Its properties are the basis for material selection, design and reliability.

The following is an overview of the main properties of FR4 materials:

Resin matrix: Usually flame retardant epoxy resin.

Reinforcement material: Electronic grade (E-glass) glass fiber cloth. The type of glass cloth (such as 106, 1080, 2116, 7628, etc.) and the weave method will affect the performance of the final laminate (such as thickness, strength, resin content).

Additives: May contain fillers (such as silica), curing agents, flame retardants (usually bromine-containing, but halogen-free FR4 is becoming increasingly popular), pigments, etc.

Electrical properties:

Dielectric constant: Usually in the range of 4.2 – 4.8 (@1MHz). This is a measure of the material’s ability to store electrical energy, which affects signal propagation speed and impedance control. Values decrease slightly with increasing frequency.

Dielectric Loss Tangent: Typically in the range of 0.015 – 0.025 (@1MHz). A measure of how much energy a material loses (heats up) in an AC electric field. The lower the loss, the better the signal integrity, which is especially important in high-frequency applications. Values increase with increasing frequency.

Volume Resistivity: Very high (>10⁸ – 10¹⁰ MΩ·cm), indicating excellent insulation properties.

Surface Resistivity: Very high (>10⁸ – 10¹⁰ MΩ), also indicating excellent insulation properties.

Electrical Strength: High (>20 kV/mm or >500 V/mil), indicating strong resistance to electrical breakdown.

Mechanical Properties:

Strength: High tensile, flexural, and impact strengths, primarily due to the reinforcement of the glass cloth. The performance is much stronger in the XY plane (along the board surface) than in the Z axis (thickness direction) (anisotropy).

Rigidity: High elastic modulus, providing good rigidity, making the PCB less likely to deform during assembly and use.

Dimensional stability: Relatively good, especially in the XY plane. Some expansion will occur after moisture absorption or at high temperatures (Z-axis changes are more significant).

Peel strength: Refers to the adhesion between the copper foil and the substrate, which is critical to PCB reliability. FR4 generally has good copper foil peel strength.

Thermal properties:

Glass transition temperature: This is one of the most critical thermal performance indicators of FR4. The Tg of standard FR4 is about 130°C – 140°C. There are medium Tg (150°C – 160°C) and high Tg (>170°C) FR4 variants. Tg is the temperature point at which the material changes from a rigid glass state to a soft rubber state. Above Tg, mechanical properties and dimensional stability will drop significantly, and CTE will increase sharply.

Thermal Decomposition Temperature: Typically >300°C, indicating the temperature at which the material begins to chemically decompose.

Thermal Expansion Coefficient:

XY CTE: Low (~12-16 ppm/°C), close to copper (~17 ppm/°C), which helps reduce thermal cycling stress.

Z CTE: Relatively high below Tg (~40-70 ppm/°C), and higher above Tg (possibly >200 ppm/°C). This is the main cause of plated-through hole failure in PCBs during multiple reflows or thermal cycles. High Tg FR4 typically has a lower Z CTE (especially above Tg), which improves reliability.

Thermal Conductivity: Low (~0.2 – 0.3 W/m·K), FR4 itself is not a good thermal conductor. Heat dissipation requires copper layers, thermal vias, or additional heat sinks.

Chemical Properties:

Solvent Resistance: Good resistance to most common solvents (e.g., alcohol, weak acids, weak bases). However, some strong solvents or long-term immersion may cause an impact.

Moisture resistance: It absorbs a small amount of moisture (moisture absorption rate is about 0.1%-0.2%). Moisture absorption will reduce insulation resistance, slightly increase dielectric constant and loss, and may cause delamination (board explosion) during high-temperature soldering. Pre-baking is usually required.

Flame retardant performance:

Meets UL94 V-0 level (one of the most stringent flame retardant levels), which is the source of “Flame Retardant” in its name. Traditional FR4 uses brominated flame retardants (such as tetrabromobisphenol A). Halogen-free FR4 uses alternative flame retardant systems such as phosphorus, nitrogen, and metal hydrates, which also meet V-0 requirements and are more environmentally friendly.

Environment and regulations:

Mainstream FR4 complies with the RoHS directive (restriction of hazardous substances).

Halogen-free FR4 meets specific standards (such as defined in JPCA-ES-01-2003, IPC-4101B, which usually requires chlorine <900ppm, bromine <900ppm, and total halogen <1500ppm).

Processability:

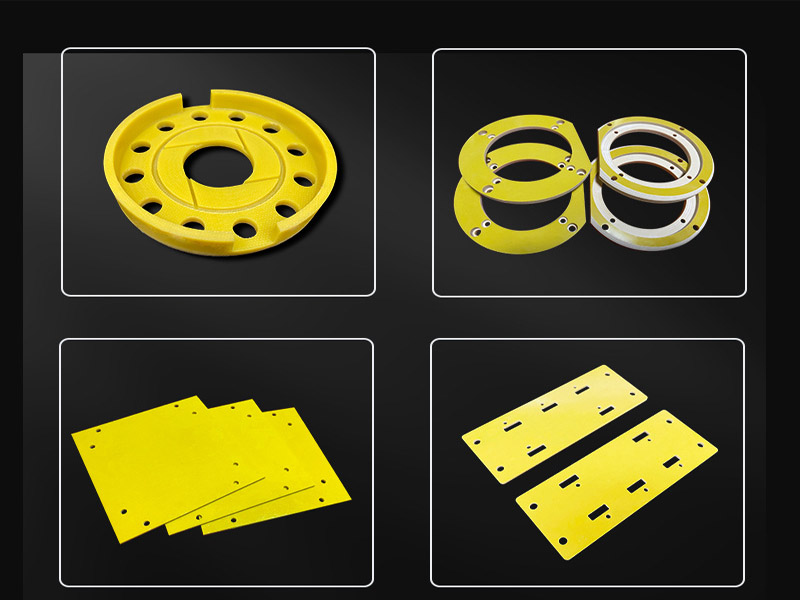

Good machinability (drilling, milling, stamping).

Compatible with standard PCB manufacturing processes (such as chemical copper plating, electroplating, etching, solder mask printing, assembly welding, etc.).

Excellent comprehensive performance:

A good balance between electrical performance, mechanical strength, thermal stability, processability and cost.

Cost-effective:

Raw material cost is relatively low and the manufacturing process is mature, which is ideal for large-scale production.

Wide availability:

Many suppliers around the world provide FR4 materials in various specifications and grades.

Good reliability:

For most commercial and industrial applications, FR4 PCBs have sufficient reliability under reasonable design and process conditions.

Flame retardancy:

Meet strict safety requirements.

Most consumer electronic products (mobile phones, computers, TVs, home appliances, etc.).

Industrial control equipment and instrumentation.

Automotive electronics (body control, infotainment, etc., often require medium/high Tg FR4 or special CAF-resistant materials).

Medical equipment (non-implantable).

Communication equipment (medium and low-end network equipment, base station auxiliary boards, etc.).

Electrical equipment (transformers, motors, etc.)

FR4 is not a single material standard: FR4 performance parameters of different manufacturers and different grades (standard Tg, medium Tg, high Tg, halogen-free, high CTI, CAF-resistant, etc.) vary significantly. When selecting, you must refer to the detailed material specification (Datasheet) provided by the specific manufacturer.

Key parameter selection: When selecting FR4, Tg, dielectric constant, loss factor, Z-axis CTE, CAF resistance, halogen-free requirements, etc. are parameters that need to be focused on, and need to be determined according to specific application requirements (operating temperature, signal frequency/rate, reliability requirements, environmental protection requirements).

In summary, FR4 firmly occupies the leading position of PCB substrate due to its excellent comprehensive performance, high cost performance and mature process. Understanding its characteristics and limitations and choosing the right FR4 grade or alternative materials according to application requirements are the key to successful electronic design.

Standard applications/cost-sensitive: Standard FR4

Lead-free process/general industry: Medium Tg FR4

Automotive electronics/thick multilayer boards: High Tg FR4

Export to EU/environmental requirements: Halogen-free FR4

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778