FR-4 Common Thickness Range FR-4 for PCB substrates: 0.2 mm – 3.2 mm (1.6 mm is the most common standard PCB thickne...

FR-4 for PCB substrates: 0.2 mm – 3.2 mm (1.6 mm is the most common standard PCB thickness)

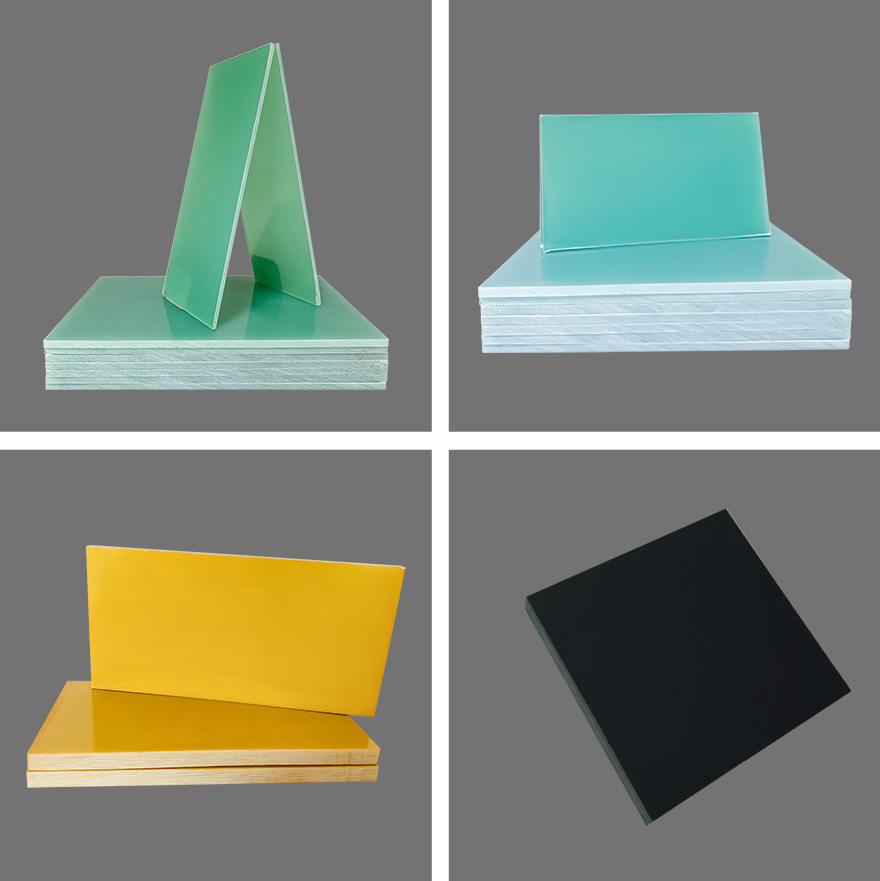

FR-4 sheets for insulation and structural parts: 0.5 mm – 5 mm (can be customized to thicker sizes, even 10 mm+)

Ultra-thin types: 0.1–0.4 mm (used in flexible/rigid-flex boards, requires special processes)

| Thickness Range | Common Applications | Features & Notes |

|---|---|---|

| 0.1–0.4 mm | Portable electronics, LED back panels, rigid section of rigid-flex boards | Ultra-thin, lightweight, low mechanical strength, prone to deformation, difficult to process |

| 0.5–0.8 mm | Handheld devices, laptops, module connection boards, low-power power supply boards | Lightweight with moderate rigidity, suitable for space-constrained devices |

| 1.0–1.6 mm | Industrial control boards, home appliance mainboards, general double-sided/multilayer PCBs | Industry standard thickness, balanced rigidity and manufacturability, low cost |

| 2.0–3.2 mm | High-power power supply boards, industrial equipment control boards, load-bearing modules | High rigidity, anti-bending, suitable for heavy components and high mechanical stress environments |

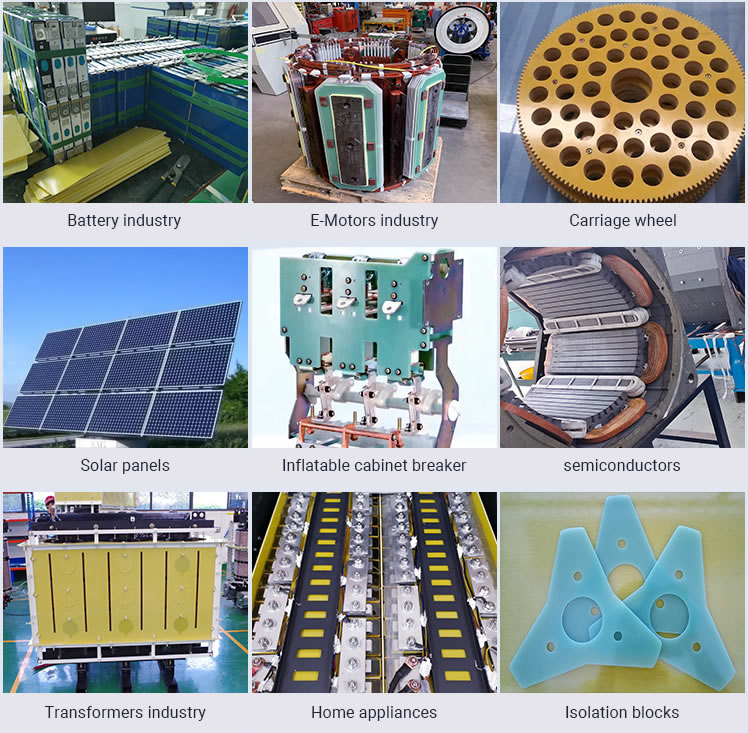

| 4–5 mm+ | Motor insulation barriers, transformer structural parts, high-voltage insulation supports | High mechanical strength, excellent insulation, ideal for structural support and high-voltage isolation |

Mechanical Strength Requirements

For heavy components and vibration resistance → choose thicker boards (≥1.6 mm)

For lightweight, portable devices → choose thinner boards (≤0.8 mm)

Insulation & Dielectric Strength

FR-4 dielectric strength is about 20 kV/mm; greater thickness provides higher insulation margin.

For high-voltage insulation, ≥2 mm thickness is recommended, and creepage distance should be calculated.

Processing & Cost

1.6 mm is the most common standard, with stable supply and low price.

Non-standard thicknesses may increase cost and lead time.

Thermal Performance

For high-temperature applications (reflow soldering, long-term >110°C), choose High-TG (≥150°C) FR-4.

Electrical Performance

For high-frequency or high-speed circuits, consider Dk/Df parameters in addition to thickness.

For PCB mainboards: 1.6 mm preferred (adjustable to 1.0–2.0 mm for special designs)

For high-voltage insulation supports: 2.0–5.0 mm (or even thicker)

For ultra-thin wearables or small modules: 0.4–0.8 mm

For high mechanical stress & power components: 2.0–3.2 mm

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778