Key Differences Between GPO-3, G10, and FR4 and How to Select the Right Material In electrical equipment, transforme...

In electrical equipment, transformers, switchgear, and industrial machinery, the performance of insulation materials directly affects the safety and reliability of the system. GPO-3, G10, and FR4 are three commonly used insulation materials. Due to differences in their composition and properties, they are suitable for different applications.

This guide explains their core differences and provides clear selection recommendations.

GPO-3 (Glass Polyester – Moulding Sheet)

Base Material: Glass fiber reinforced unsaturated polyester resin

Features: UL94 V-0 flame retardant, excellent arc resistance, high tracking resistance, medium-high mechanical strength

Manufacturing Method: Mold-pressed sheets (thick, dimensionally stable, not easy to deform)

G10 (Glass Epoxy – Non-Flame Retardant)

Base Material: Glass fiber cloth + pure epoxy resin

Features: Extremely high mechanical strength, excellent moisture resistance, but non-flame-retardant

Standard: NEMA G10

FR4 (Glass Epoxy – Flame Retardant)

Base Material: Glass fiber cloth + epoxy resin + flame-retardant additives

Features: High mechanical strength, good electrical properties, UL94 V-0 flame retardant.

Considered the flame-retardant upgrade of G10.

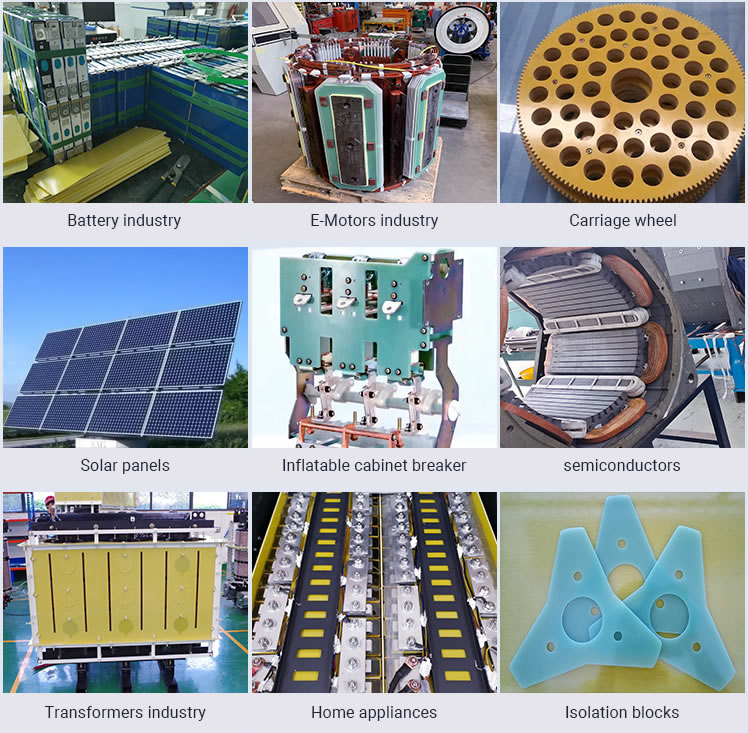

Most widely used: PCB, motors, generators, transformers, etc.

| Performance Index | GPO-3 | G10 | FR4 |

|---|---|---|---|

| Flame Resistance | ★★★★★ | ★☆☆☆☆ (Non-FR) | ★★★★★ |

| Mechanical Strength | ★★★★☆ | ★★★★★ (Highest) | ★★★★★ |

| Arc Resistance | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| CTI / Tracking Resistance | >600V (Excellent) | Medium | Medium |

| Moisture Resistance | ★★★★☆ | ★★★★★ | ★★★★★ |

| Thermal Class | Class B (130°C) | Class F (155°C) | Class F–H (155°C–180°C) |

| Machinability | Excellent | Excellent | Excellent |

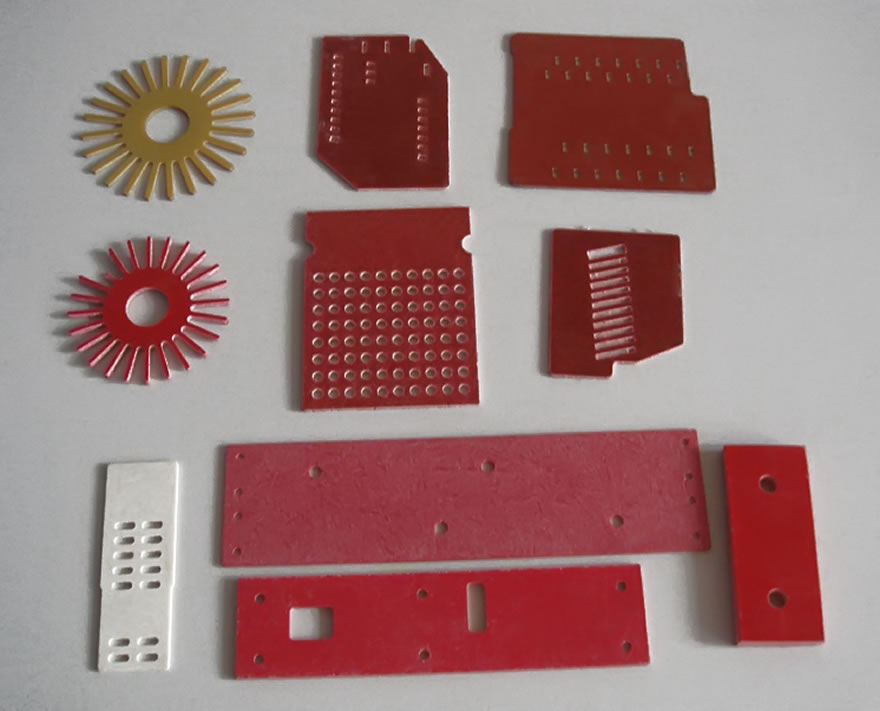

GPO-3 Applications

Suitable for structural insulation parts requiring stable electrical properties and strong arc resistance:

Switchgear internal insulation barriers & partitions

Busway phase barriers and separators

Transformer end plates and coil press plates

Electrical enclosure insulation components

Railway, elevator, and industrial control cabinet insulation parts

Keywords: Flame-retardant + Arc-resistant + Structural parts

G10 Applications

Ideal for applications requiring extremely high mechanical strength without mandatory flame-retardant requirements:

Mechanical fixtures, jigs, precision supports

Aerospace components

Insulation parts for high-humidity environments

Motor end caps and support rings (non-FR)

Keywords: High mechanical strength + No flame-retardant requirement

FR4 Applications

The most common choice where both flame retardancy and high electrical performance are required:

PCB boards

Generator insulation barriers, stator/rotor slot wedges

Transformer spacers, supports, insulation blocks

Motor end caps and structural insulation components

Precision machined insulation parts

Keywords: Flame-retardant + High strength + High electrical insulation

If flame retardancy is required

Choose FR4 or GPO-3

High strength needed → FR4

High arc resistance / thick sheets → GPO-3

If extremely high mechanical strength is needed but no FR requirement →

Choose G10

For switchgear or busway systems →

GPO-3 (best arc resistance and cost-effective)

For generators or transformers →

FR4 (stable electrical & thermal performance)

For high-humidity environments →

G10 or FR4

| Machining Requirement | Recommended Material |

|---|---|

| Large, thick structural parts | GPO-3 |

| Precision machining, threaded parts | G10 / FR4 |

| Flame-retardant precision parts | FR4 |

| High arc resistance | GPO-3 |

GPO-3 = Best for switchgear & busway structural insulation (Flame-retardant + Arc-resistant)

G10 = Highest mechanical strength, non-FR (Mechanical parts specialist)

FR4 = Most universal high-strength flame-retardant insulation board (Motors/transformers general use)

XUJUE ELECTRICAL is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 65 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you need to know more about GPO-3,FR4,G10 epoxy sheets and other insulation materials product information and quotations, please contact us, we can mail you samples for your testing.

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778