Epoxy glass fiber winding tube processing and customization

Introduction to epoxy glass fiber winding tube Epoxy glass fiber winding tube is made of glass fiber impregnated wi...

Introduction to epoxy glass fiber winding tube

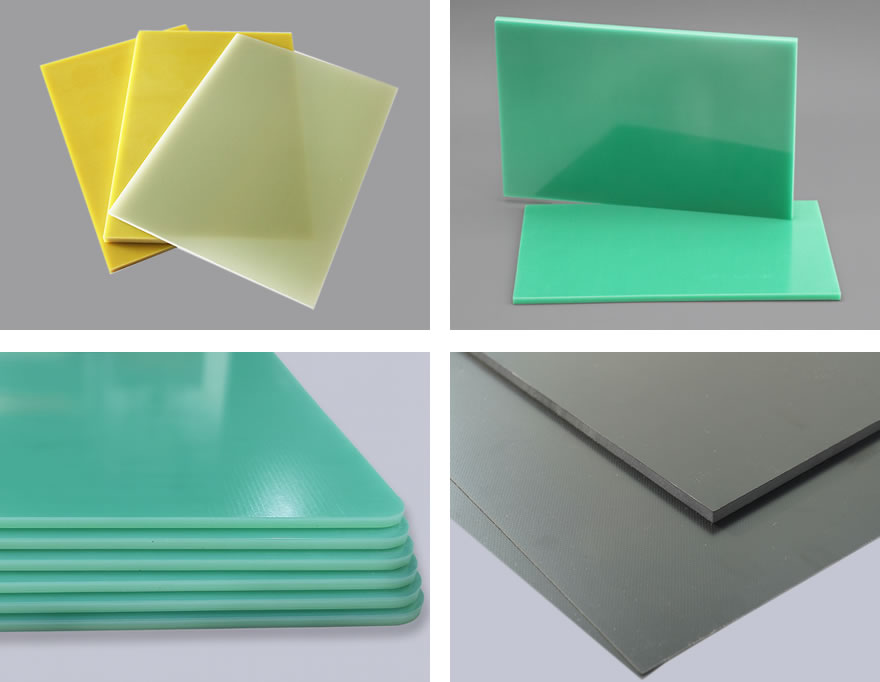

Epoxy glass fiber winding tube is made of glass fiber impregnated with insulating colloids of different resin ratios such as epoxy, wet rolled and cured by heat baking. This product has high temperature resistance, reaching H level, good electrical and mechanical properties, low dielectric loss, no deformation and no stratification, chemical corrosion resistance (SF6 resistance) and other characteristics.

It is widely used as the main insulator of H-class dry-type transformers, on-load tap changers, reactors, lightning arresters, SF6 transformers and other products.

Epoxy glass fiber winding tube processing and customization

XUJUE ELECTRICAL provides various electrical grade glass fiber winding tubes with inner diameters of 6mm-1000mm and lengths generally less than 3.2 meters. The length can be customized according to needs. The winding angle can be controlled between 30 degrees and 90 degrees, and can be treated to resist SF6. Various punching, grooving, cutting, processing of internal or external threads, etc. can be provided.

Epoxy glass fiber winding tube Technical Parameters

Executive Standard:GB-T 23100-2008 IEC61212-2006

| Number | Item | Unit | Value |

| 1 | Density | G/Cm3 | 1.95-2.1 |

| 2 | Flexural Strength At Perpendicular Lamination (Under Normal) |

MPa | 400 |

| 3 | Axial Compressive Strength | MPa | ≥150 |

| 4 | Breakdown Voltage At Parallel Lamination (Transformer Oil At 90℃) |

Kv | ≥40 |

| 5 | Dielectric Strength At Perpendicular Lamination (Transformer Oil At 90℃, 1mm) |

KV/Mm | ≥11.6 |

| 6 | Surface Voltage Resistance After Damp | Kv | ≥12 |

| 7 | Insulation Resistance After Immersion | Ω | 1.0×103 |

| 8 | Dielectric Loss Factor(50Hz) | – | ≤0.05 |

| 9 | Water Absorption | % | ≤1 |

| 10 | Partial Discharge | PC | ≤5 |

| 11 | Thermal Index | – | 180 |

Product Specification

| Product specification | 3520 | 380/380A | 3640/3641 | 355 | 356 | 3652 | 364 | 360 |

| PFCP22 | PFCC21/24 | EPGC21/22 | – | – | SIGC21 | BMIGC21 | EPCF52 | |

| Min Wall Thickness(mm) | 2.0 | 3.0 | ||||||

| Max Wall Thickness(mm) | 80 | 200 | 200 | 200 | 200 | 200 | 200 | – |

| Min Inside Diameter(mm) | 10 | 10 | 6 | 6 | 6 | 10 | 10 | 30 |

| Max Inside Diameter(mm) | 1200 | 600 | ||||||

| Length(mm) | 1000 | 1000/1200 | 1000-3000 | |||||

Epoxy glass fiber winding tube mold table (partial)

Small winding tube workshop mold

| Small winding tube workshop mold | ||

| Mold diameter * length (φ)mm |

Mold diameter * length (φ)mm |

Mold diameter * length (φ)mm |

| 16*2000 | 43*2000 | 70*2000 |

| 20*2000 | 44*1800 | 72*2000 |

| 22*2000 | 48*2000 | 73*2000 |

| 30*2000 | 50*1800 | 73.5*2000 |

| 32*2000 | 52*1500 | 75*2000 |

| 33*2000 | 54*2000 | 77.5*2000 |

| 36*2000 | 55*2000 | 76*2000 |

| 36.5*2000 | 57*1500 | 90*2000 |

| 38*2000 | 58*2000 | 95*1500 |

| 40*2000 | 59.5*2000 | 95*2000 |

| 41*2000 | 61*2000 | 97*2000 |

| 41*1800 | 63*1500 | |

| 42*2000 | 67*2000 | |

Large winding tube workshop mold

| large winding tube workshop mold | |||

| Mold diameter(φ)mm | Mold length mm | Mold diameter(φ)mm | Mold length mm |

| 100 | 3100 | 345 | 2750 |

| 100 | 2750 | 350 | 3300 |

| 105 | 3100 | 350 | 3100 |

| 110 | 3100 | 355 | 3100 |

| 115 | 2750 | 355 | 2750 |

| 116 | 3100 | 360 | 3100 |

| 116 | 2750 | 365 | 3100 |

| 120 | 4000 | 365 | 2750 |

| 120 | 3250 | 370 | 3100 |

| 125 | 3250 | 375 | 3250 |

| 130 | 3100 | 375 | 3250 |

| 135 | 3100 | 380 | 3100 |

| 140 | 3100 | 380 | 2750 |

| 145 | 3100 | 385 | 3100 |

| 145.89 | 3200 | 385 | 2750 |

| 145.3 | 3100 | 390 | 3100 |

| 145.9 | 3100 | 395 | 3100 |

| 145.85 | 3100 | 395 | 2750 |

| 146.2 | 3100 | 400 | 3200 |

| 146.1 | 3100 | 400 | 2750 |

| 150 | 3100 | 405 | 3100 |

| 155 | 3100 | 405 | 2750 |

| 155 | 3200 | 410 | 3100 |

| 160 | 3100 | 410 | 3150 |

| 165 | 3300 | 415 | 3100 |

| 165 | 3200 | 420 | 3100 |

| 170 | 3100 | 425 | 3100 |

| 170 | 2750 | 425 | 2750 |

| 175 | 2800 | 430 | 3100 |

| 180 | 3100 | 430 | 2750 |

| 180 | 2750 | 435 | 3100 |

| 185 | 3100 | 435 | 2700 |

| 185 | 2750 | 440 | 3100 |

| 190 | 3100 | 440 | 2750 |

| 195 | 3100 | 445 | 3100 |

| 195 | 2750 | 450 | 3200 |

| 200 | 3100 | 455 | 3100 |

| 200 | 2750 | 460 | 3200 |

| 205 | 3100 | 460 | 3250 |

| 210 | 3100 | 465 | 3100 |

| 210 | 2750 | 470 | 3200 |

| 215 | 3100 | 470 | 2800 |

| 215 | 2750 | 475 | 2800 |

| 220 | 3100 | 480 | 3100 |

| 225 | 3300 | 480 | 3150 |

| 225 | 3100 | 484.6 | 3200 |

| 230 | 3100 | 484.8 | 3200 |

| 230 | 2750 | 485 | 3100 |

| 235 | 3100 | 490 | 3100 |

| 235 | 2750 | 495 | 3000 |

| 240 | 3100 | 495 | 3200 |

| 240 | 2750 | 496 | 3200 |

| 245 | 3100 | 500 | 3100 |

| 245 | 2750 | 505 | 3200 |

| 250 | 3100 | 510 | 3200 |

| 250 | 2750 | 515 | 2800 |

| 255 | 3300 | 520 | 3100 |

| 255 | 3100 | 525 | 3100 |

| 260 | 3100 | 530 | 3200 |

| 260 | 3200 | 535 | 3200 |

| 260 | 2750 | 540 | 3200 |

| 265 | 3100 | 540 | 2750 |

| 265 | 2750 | 550 | 3200 |

| 270 | 3100 | 555 | 3200 |

| 270 | 2750 | 560 | 3100 |

| 275 | 3100 | 560 | 3400 |

| 275 | 2750 | 580 | 2800 |

| 280 | 3100 | 590 | 3200 |

| 280 | 2750 | 604 | 2800 |

| 285 | 3100 | 620 | 3100 |

| 285 | 3200 | 630 | 2800 |

| 285 | 2800 | 640 | 3200 |

| 290 | 3100 | 650 | 3200 |

| 290 | 2750 | 670 | 3200 |

| 295 | 3100 | 676 | 2800 |

| 295 | 2750 | 685 | 3200 |

| 300 | 3000 | 725 | 3200 |

| 300 | 3100 | 750 | 3200 |

| 300 | 2750 | 777.77 | 3100 |

| 305 | 3100 | 800 | 3000 |

| 305 | 3300 | 884 | 3000 |

| 305 | 2750 | 1044 | 2800 |

| 310 | 3100 | 1080 | 3200 |

| 310 | 2750 | ||

| 315 | 3100 | ||

| 315 | 2750 | ||

| 320 | 3100 | ||

| 320 | 3200 | ||

| 325 | 3100 | ||

| 330 | 3100 | ||

| 330 | 2800 | ||

| 335 | 3100 | ||

| 335 | 2750 | ||

| 340 | 3100 | ||

| 340 | 2750 | ||

| 345 | 3100 | ||

The above mold table is for reference only. The template material is mainly steel, supplemented by epoxy material.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers