Why DMD Insulation Paper Is Preferred in EV Traction Motors

With the rapid development of electric vehicles, traction motors are required to operate under higher voltages, highe...

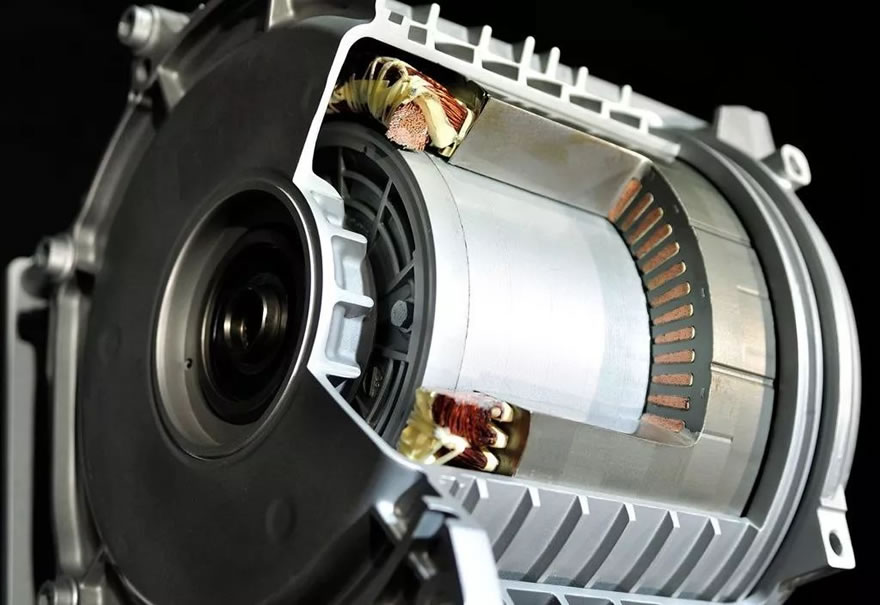

With the rapid development of electric vehicles, traction motors are required to operate under higher voltages, higher power density, higher rotational speed, and harsher thermal and mechanical conditions. As a result, the insulation system has become a critical factor affecting motor reliability and service life.

Among various insulation materials, DMD insulation paper (Non-woven Fabric/ Polyester Film / Non-woven Fabric/) has become the preferred and most widely used insulation solution for EV traction motors.

1.Balanced Electrical and Mechanical Performance

DMD insulation paper offers an excellent balance between dielectric strength and mechanical durability.

The polyester film layers provide reliable electrical insulation, while the non-woven core enhances tear resistance, impact strength, and structural stability.

This composite structure effectively prevents slot-to-core and phase-to-phase electrical breakdown, even under high-speed rotation and continuous vibration conditions.

2.Proven Suitability for High-Voltage EV Platforms (400V / 800V)

Modern EV traction motors typically operate on 400V and 800V DC platforms, generating steep voltage gradients and high dv/dt stress.

DMD insulation paper provides:

High breakdown voltage

Uniform and stable thickness

Low electrical failure risk

These properties make DMD highly suitable for both conventional and high-voltage EV motor designs.

3.Excellent Processability for Automated Motor Manufacturing

One of the key reasons DMD insulation paper is preferred is its superior processing performance.

DMD features:

High flexibility

Smooth surface

Low risk of edge damage and burrs

This makes it ideal for:

Automated slot liner insertion

Hairpin (flat wire) motor manufacturing

High-volume, automated production lines

Compared with NMN and NHN, DMD significantly reduces insertion damage and improves manufacturing efficiency.

4.Reliable Thermal Endurance for EV Operating Conditions

DMD insulation paper is available in Class F (155°C) and Class H (180°C) thermal ratings, which fully meet the long-term thermal requirements of most EV traction motors.

While NMN and NHN offer higher thermal limits, DMD provides sufficient thermal endurance for the majority of EV applications, without unnecessary increases in material cost.

5.Proven Long-Term Reliability and Industry Acceptance

DMD insulation paper has been used in motor insulation systems for decades and has a proven track record in:

Thermal aging resistance

Mechanical stability

Electrical reliability

Its performance has been extensively validated in both traditional industrial motors and modern EV traction motors, making it a trusted and standardized insulation material across the industry.

6.Optimal Cost-Performance Ratio

Compared with NMN and NHN insulation materials, DMD insulation paper delivers:

Comparable electrical performance for most EV motors

Lower material and processing costs

Reduced manufacturing losses

This optimal balance between performance and cost is a key reason why DMD remains the primary insulation choice for mass-produced EV traction motors.

Conclusion

DMD insulation paper is preferred in EV traction motors because it offers the best overall balance of electrical insulation, mechanical strength, thermal endurance, manufacturing efficiency, and cost effectiveness.

In practical EV motor designs, DMD insulation paper is widely used as the main slot liner and phase insulation, while NMN or NHN insulation paper is typically applied only as local reinforcement in high-temperature areas.

Manufacturer selection and obtaining quotes

XUJUE ELECTRICAL has over 65 years of experience in producing DMD insulation materials ensuring reliable quality and stable performance. Throughout customer service, Xujue’s professional team can provide suitable specifications and models of DMD insulation materials based on the specific requirements and application scenarios of Motor manufacturing. Whether for small batches or large-scale production, Xujue responds promptly, offering attentive service and high-quality products.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted