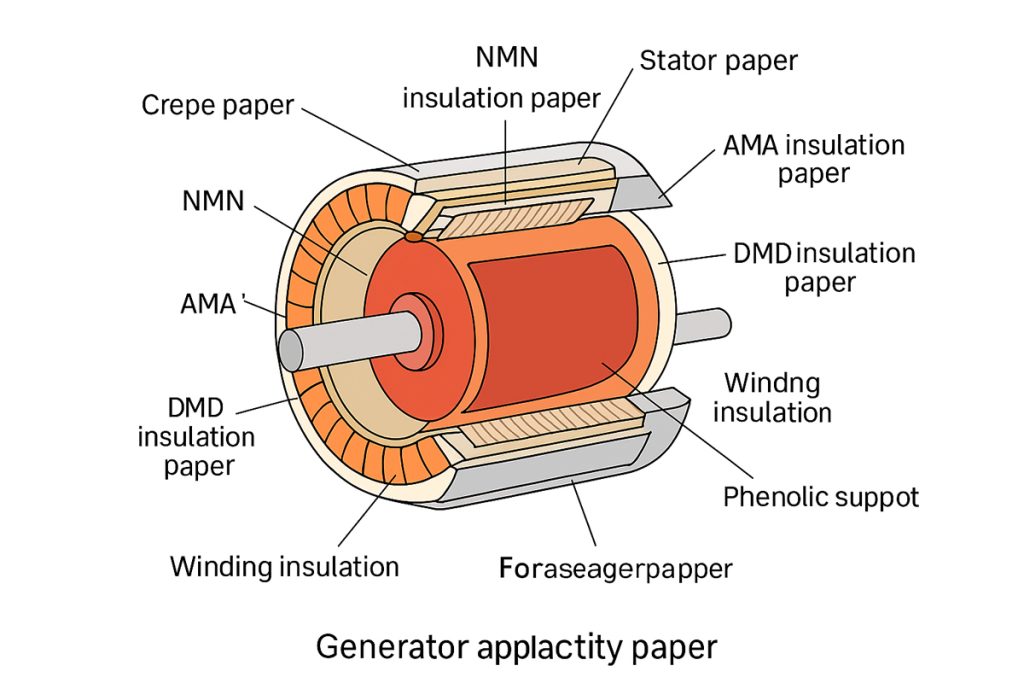

Types of insulation paper for generators and how to select them

Insulation paper for generators is mainly used for winding insulation, interlayer insulation and slot insulation to e...

Insulation paper for generators is mainly used for winding insulation, interlayer insulation and slot insulation to ensure the safety and reliability of motors or generators under high voltage, high temperature and long-term operation conditions.

1. Comparison Table of Insulation Paper Types for Generators

| Insulation Paper Type | Main Application | Temperature Class | Key Features | Typical Applications |

|---|---|---|---|---|

| NMN Paper | Inter-layer insulation, winding insulation | Class B (130℃) ~ Class F (155℃) | Good mechanical strength, voltage resistance, cost-effective | General industrial generators, low-voltage windings |

| AMA Paper | High-temperature windings, inter-layer insulation | Class H (180℃) | High-temperature resistance, excellent flexibility, moisture resistant | Hoist motors, metallurgical motors, marine generators |

| Crepe Paper | Slot insulation, inter-layer insulation | Class F (155℃) ~ Class H (180℃) | High elongation, flexible, easy to tightly fill windings | High-voltage windings, dry-type transformers, generator slot insulation |

| DMD Paper (Pre-impregnated) | Inter-layer insulation, winding insulation | Class H (180℃) | High mechanical strength, chemical resistance, improves heat dissipation | Dry-type transformers, high-temperature generators, long-life equipment |

| Phenolic Tube / Fabric Tube | Slot support, end fixation | Class H (180℃) ~ 220℃ | High mechanical strength, high-temperature resistant, chemically resistant | Stator slot wedges, winding support, rotor end fixation |

| High-Temperature Specialty Paper | Extreme high-temperature windings, critical insulation | Above 220℃ | High-temperature resistant, long life, highly reliable | Aerospace generators, military equipment, high-temperature industrial generators |

2. Guidelines for Selecting Insulation Paper

Select by Temperature Class

Class B (130℃), F (155℃), H (180℃), >220℃.

Generator operating temperature ≤ insulation paper temperature class × safety factor (typically 1.2–1.3).

Select by Application Location

Slot insulation: Choose paper with good flexibility and elongation, e.g., Crepe Paper or pre-impregnated DMD.

Inter-layer insulation: Choose paper with high mechanical strength and heat resistance, e.g., NMN, AMA, or DMD.

End support / stator slot wedges: Use phenolic tube/fabric tube for mechanical support.

Select by Operating Environment

High temperature, high humidity, or corrosive environments → AMA or DMD.

General industrial environment → NMN is sufficient.

Consider Mechanical Processing

For thick sheets or complex winding shapes → pre-impregnated DMD and Crepe Paper are easier to process and reduce stress concentration.

Consider Cost-effectiveness

Ordinary low-voltage windings → NMN is the most economical.

High-temperature or high-reliability windings → AMA or DMD, although more expensive, offer longer life and higher reliability.

Summary of Selection Strategy:

1.Determine the generator’s operating temperature and insulation class → choose paper with suitable temperature rating.

2.Select material based on location (slot, inter-layer, end support) → flexible or mechanically strong paper as appropriate.

3.Combine environmental conditions and cost → finalize material choice.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308