Transformer Insulation Materials: Importance for Power System Stability

The Importance of Insulation Materials in Transformers and Their Impact on Power System Stability In modern power sy...

The Importance of Insulation Materials in Transformers and Their Impact on Power System Stability

In modern power systems, transformers are core equipment responsible for voltage conversion and power transmission. During transformer design, manufacturing, and long-term operation, the performance of insulation materials directly determines the safety, reliability, and overall stability of the power system. The insulation system can be regarded as the “lifeline” of a transformer.

This article provides a comprehensive explanation of the critical role of insulation materials in transformers and their importance to stable power system operation.

1. Fundamental Functions of Transformer Insulation Systems

Transformers contain complex internal structures with conductors, cores, and metal components operating at different voltage levels. Insulation materials play several essential roles:

Electrical Insulation

They prevent electrical breakdown or short circuits between high-voltage and low-voltage windings, as well as between windings and the core, ensuring safe operation.

Mechanical Support

Insulation materials provide stable support for windings and conductors, withstanding short-circuit forces, vibration, and transportation stress to prevent displacement or deformation.

Thermal Stability and Heat Management

Under high-load operation, insulation materials must endure elevated temperatures over long periods while working together with oil or air to dissipate heat effectively.

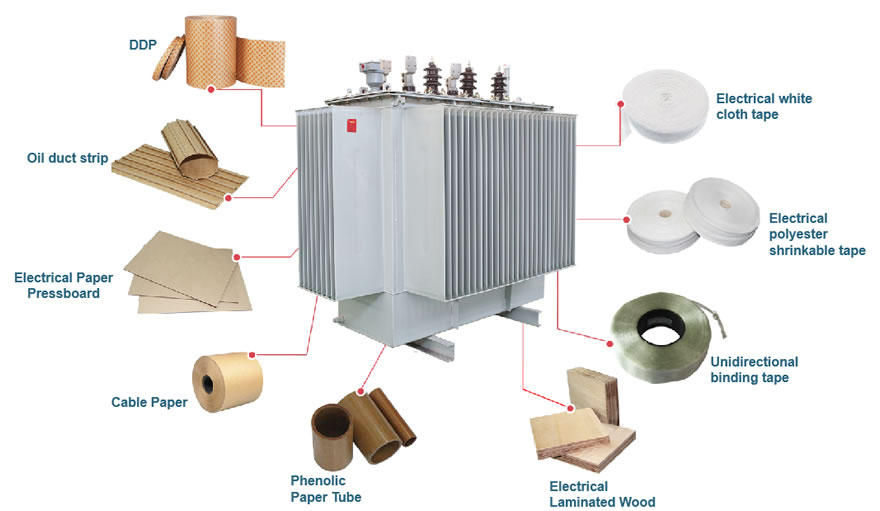

2. Common Types of Insulation Materials Used in Transformers

Different transformer types (oil-immersed and dry-type) require different insulation material solutions:

Solid Insulation Materials

Insulating paper and pressboard

Epoxy glass fiber laminates (such as G10, G11, FR4)

Composite insulation materials (such as NHN and NMN)

These materials are widely used for interlayer insulation, turn-to-turn insulation, structural support, and electrical isolation.

Liquid Insulation Materials

Mineral insulating oil

Natural ester oil and synthetic ester oil

Liquid insulation provides both electrical insulation and cooling, making it essential for oil-immersed transformers.

Gas and Resin Insulation

Air insulation (dry-type transformers)

Epoxy resin cast insulation (cast resin transformers)

These systems are commonly applied in environments with high fire-safety and explosion-proof requirements.

3. Impact of Insulation Materials on Transformer Reliability

Determining Dielectric Strength and Safety Margins

High-quality insulation materials offer superior dielectric strength, effectively resisting lightning impulses, voltage fluctuations, and switching overvoltages.

Influencing Service Life

Insulation aging is one of the primary factors limiting transformer lifespan. Materials with higher thermal endurance and excellent aging resistance can significantly extend service life.

Reducing Failure Rates and Maintenance Costs

A stable insulation system minimizes risks such as partial discharge and insulation breakdown, reducing unplanned outages and long-term maintenance costs.

4. Relationship Between Insulation Materials and Power System Stability

Preventing the Spread of System-Level Failures

Insulation failure in a single transformer can trigger line trips, regional blackouts, or even large-scale grid instability.

Enhancing Power Grid Reliability

High-reliability transformers are fundamental to continuous power supply, with insulation performance being one of the most critical indicators.

Supporting Renewable Energy and High-Load Applications

In photovoltaic, wind power, energy storage, and electric transportation systems, transformers often operate under sustained high loads, placing higher demands on the thermal and electrical stability of insulation materials.

5. How to Select Insulation Materials for Transformers Scientifically

In practical engineering and manufacturing, the following factors should be carefully evaluated:

Thermal class (e.g., Class B, F, H)

Dielectric strength and partial discharge performance

Mechanical strength and dimensional stability

Moisture resistance, oil resistance, and aging resistance

Compliance with international standards such as IEC, IEEE, and UL

These considerations are especially important for export-oriented products and overseas power projects.

6. Conclusion

Although insulation materials are not the most visible components of a transformer, they are decisive factors in performance and service life. High-performance insulation materials not only ensure the safe operation of individual transformers but also form a critical foundation for stable, efficient, and sustainable power system development.

As power systems continue to evolve toward higher voltages, larger capacities, and greener energy solutions, advancements in insulation material technology will remain indispensable.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted