The Role of Pressboard in the Insulation System of Oil-Immersed Transformers

The Role of Pressboard in Oil-Immersed Transformers Pressboard is one of the core solid insulation materials in oil-...

The Role of Pressboard in Oil-Immersed Transformers

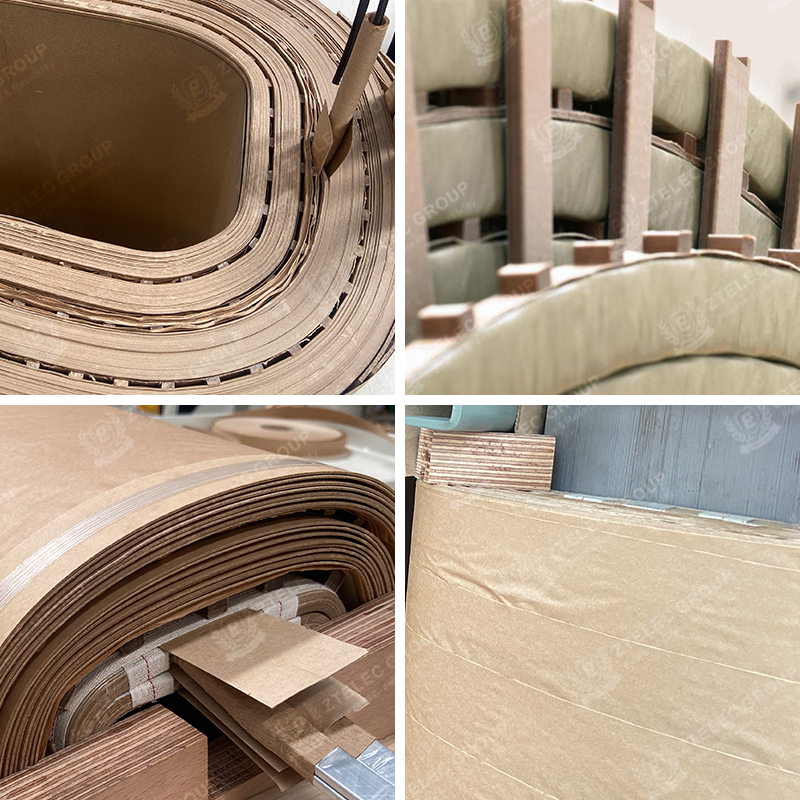

Pressboard is one of the core solid insulation materials in oil-immersed transformers. Together with transformer oil, it forms the oil–paper composite insulation system, which directly affects the electrical safety, mechanical stability, and service life of the transformer. The following explains its role from both the insulation mechanism and practical application perspectives.

1. Main Functions of Pressboard in Oil-Immersed Transformers

Critical Electrical Insulation Function

Pressboard features high dielectric strength and stable insulation performance. When fully impregnated with oil, it significantly enhances the overall insulation level of the transformer and is mainly used for:

Main insulation between high-voltage and low-voltage windings

Insulation between windings and the core or clamping structures

Reinforced insulation between winding layers and sections

In combination with transformer oil, pressboard effectively suppresses partial discharge and improves withstand voltage capability.

Mechanical Support and Structural Stability

Oil-immersed transformers are subjected to strong electrodynamic forces during operation and short-circuit conditions. Pressboard provides:

Excellent compressive strength and bending resistance

Stable dimensional integrity

Typical applications include:

Winding end supports

Insulating spacers and pressure plates

Oil duct barriers and supporting structures

These components ensure long-term mechanical stability of the windings.

Formation of Oil Ducts and Improved Heat Dissipation

Properly designed pressboard structures help form axial or radial oil ducts, which:

Promote transformer oil circulation

Enhance heat dissipation from windings and the core

Reduce local hot-spot temperatures

This function is particularly important for medium- and large-capacity oil-immersed transformers.

Extended Insulation Service Life

High-purity pressboard offers:

Excellent oil absorption capability

High compatibility with mineral transformer oil

After full oil impregnation, pressboard reduces internal electric field stress and slows insulation aging, making it one of the most critical materials determining transformer service life.

2. Typical Applications of Pressboard in Oil-Immersed Transformers

| Application Area | Function Description |

|---|---|

| Winding end insulation | Prevents electric field concentration |

| Main insulation cylinders | Separation between HV and LV windings |

| Insulating spacers | Mechanical support and oil duct formation |

| Core-to-winding barriers | Prevents creepage and electrical breakdown |

| Lead and clamping insulation | Improves insulation safety margins |

3. Key Selection Criteria for Pressboard in Oil-Immersed Transformers

From a transformer insulation material selection perspective, the following parameters are commonly emphasized:

Thermal class: Typically Class A (105 °C) or upgraded heat-resistant pressboard

Thickness range: 0.5–6.0 mm, depending on structural requirements

Dielectric strength: Must comply with IEC, GB, or ASTM standards

Moisture content and purity: Directly affect insulation aging in oil

Processability: Suitable for punching, hot pressing, and CNC machining

4. Conclusion

Pressboard in oil-immersed transformers not only serves as an electrical insulation material but also provides mechanical support and forms heat dissipation channels. It is an irreplaceable component of the oil–paper insulation system. Proper material selection and strict quality control are essential to ensure long-term safe and reliable transformer operation.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted