Phenolic Paper Laminate VS Phenolic Cotton Cloth Laminate

1. Differences Between Phenolic Paper Laminate and Phenolic Cotton Cloth Laminate Comparison Item Phenoli...

1. Differences Between Phenolic Paper Laminate and Phenolic Cotton Cloth Laminate

| Comparison Item | Phenolic Paper Laminate (PF Paper) | Phenolic Cotton Cloth Laminate (PF Cotton Cloth) |

|---|---|---|

| Reinforcement Material | Insulating paper (cellulose) | Cotton fabric (woven yarn) |

| Mechanical Strength | Medium, relatively brittle | High, strong impact and tensile resistance |

| Electrical Insulation | Excellent | Good, slightly lower than paper laminate |

| Wear Resistance | Poor | Excellent, suitable for frictional parts |

| Machinability | Easy to cut, drill, and process | Good, but harder; wears tools more |

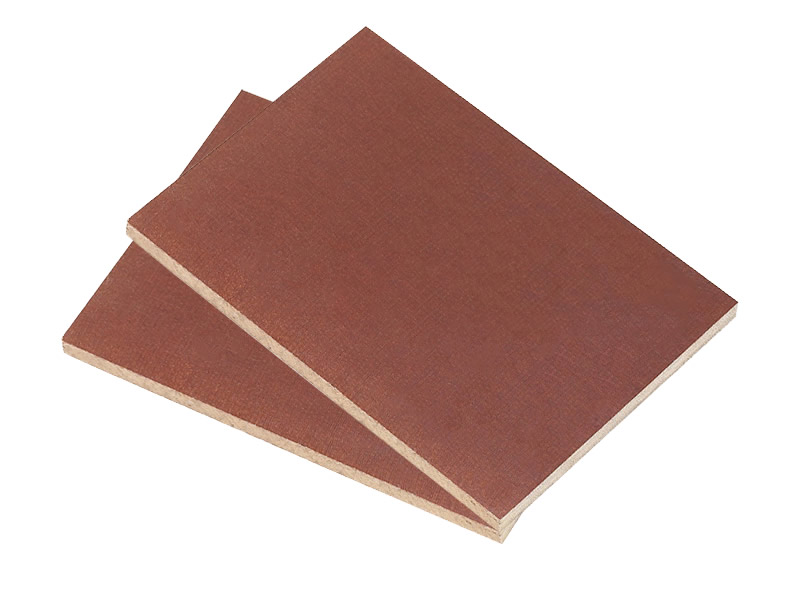

| Appearance | Brown, smooth surface | Dark brown, with visible fabric texture |

| Cost | Low | Relatively higher |

| Temperature Resistance | Generally ≤120°C | Generally ≤140°C, better heat resistance |

Phenolic Cotton Cloth Laminate

2. How to Select the Right Material?

Selection should be based on application environment, mechanical performance, electrical requirements, and cost considerations:

Application-Based Recommendations

| Application Requirement | Recommended Material |

|---|---|

| General electrical insulation (e.g., spacers, washers) | Phenolic Paper Laminate |

| Medium-load mechanical components | Phenolic Cotton Cloth Laminate |

| Wear-resistant sliding parts (e.g., sliders, bushings, bearing seats) | Phenolic Cotton Cloth Laminate |

| Cost-sensitive, non-load-bearing mass parts | Phenolic Paper Laminate |

| High-impact, high-load, friction environments | Phenolic Cotton Cloth Laminate |

If your priority is: excellent insulation, easy machining, low cost → choose Phenolic Paper Laminate

If your priority is: high mechanical strength, wear resistance, durability → choose Phenolic Cotton Cloth Laminate

phenolic paper sheet

3. Additional Selection Considerations

For high-temperature applications, consider heat-resistant cotton cloth laminate or upgrade to epoxy-based laminates (such as G10 or G11).

Do not use phenolic paper laminate in high mechanical stress environments to avoid cracking or failure.

For complex machining requirements, phenolic paper laminate is more suitable due to easier processing.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations