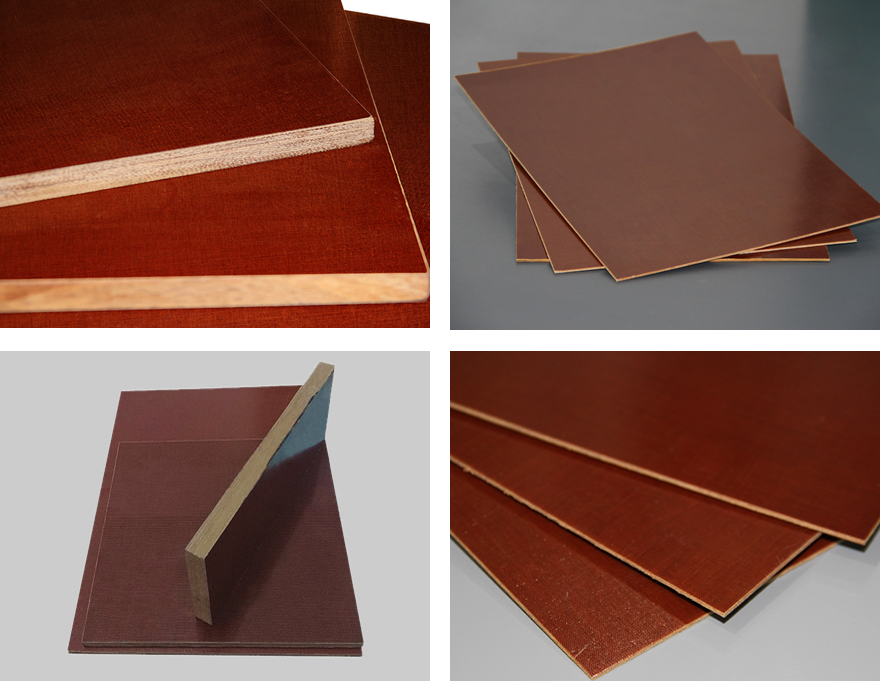

Phenolic Cotton Cloth Sheet for Material Processing Applications

Applications of Phenolic Cotton Cloth Sheet in the Material Processing Industry Phenolic cotton cloth sheet (Phenoli...

Applications of Phenolic Cotton Cloth Sheet in the Material Processing Industry

Phenolic cotton cloth sheet (Phenolic Cotton Cloth Laminate) is a composite material made by impregnating cotton fabric with phenolic resin and laminating it under high temperature and pressure. With its high mechanical strength, excellent wear resistance, good electrical insulation, and vibration damping, it is widely used in the material processing industry.

1. Mechanical Component Processing

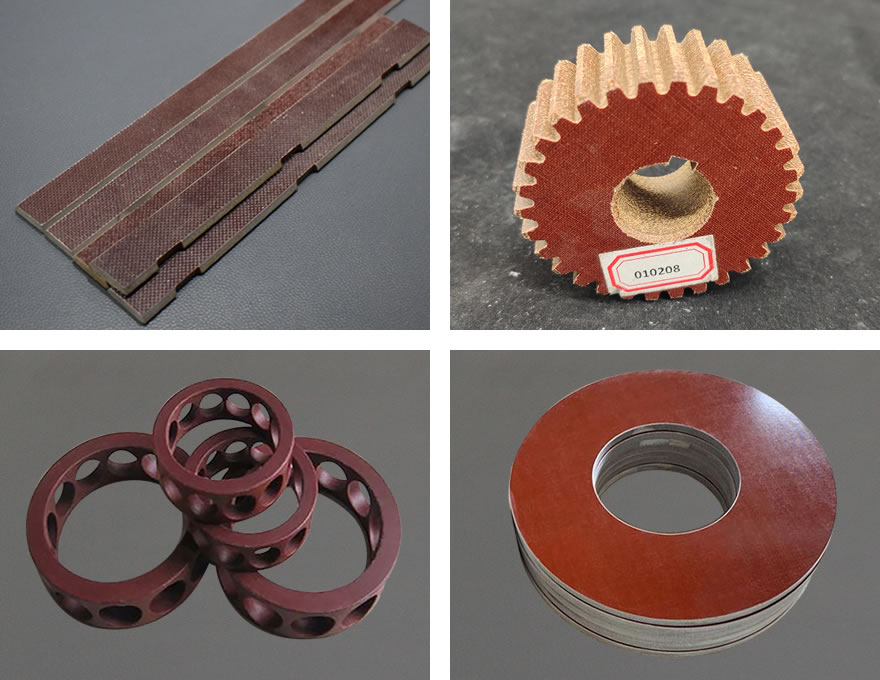

Bearings and Bushings: With good wear resistance and self-lubricating properties, it is suitable for sliding bearings and bushings under low-speed and medium-load conditions.

Gears and Pulleys: Lightweight and low-noise operation, making it a good substitute for certain metal parts, while extending equipment service life.

Guides and Support Components: With strong vibration absorption, it is often used in machine tools and light machinery for support or positioning.

2. Tooling and Fixture Manufacturing

Machining Fixtures: With moderate hardness and easy machinability, it is suitable for fixture bases and positioning blocks.

Insulating Tooling: Commonly used as insulating carriers or spacers in processes involving electrical machining.

Friction Plates and Brake Pads: Due to stable friction coefficient and wear resistance, it is applied in certain friction tooling and braking systems.

3. Electrical Processing Industry

Insulating Partitions: Used in motors, generators, and transformers for insulation and structural support.

Machine Tool Electrical Components: Applied in control cabinets, electrical panels, and insulating supports.

Low-voltage Insulating Parts: Suitable for parts of electrical processing equipment where high mechanical strength and moderate electrical insulation are required.

4. Material Substitution and Optimization

Metal Replacement: In light-load, low-speed applications, it can replace steel, copper, and other metals to reduce weight and cost.

Engineering Plastic Replacement: Compared with some engineering plastics (such as nylon), phenolic cotton cloth sheet provides better wear resistance and dimensional stability.

5. Processing Advantages

Easy to turn, mill, drill, and saw, suitable for customized shaped parts.

Can be cut into various thicknesses and dimensions as required.

Excellent surface friction properties, ideal for motion and wear-resistant components.

Conclusion:

In the material processing industry, phenolic cotton cloth sheet is mainly applied in mechanical components, tooling fixtures, electrical insulation parts, and friction elements. With its high cost-performance ratio, wear resistance, and machinability, it has become an ideal alternative to traditional metals and some engineering plastics.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308