Performance Analysis of GPO-3 and G10 Materials

Performance Analysis of GPO-3 and G10 Materials (Comprehensive Comparison) GPO-3 material and G10 materail are both ...

Performance Analysis of GPO-3 and G10 Materials (Comprehensive Comparison)

GPO-3 material and G10 materail are both glass-fiber-reinforced insulating materials, but they differ significantly in structural composition, resin systems, manufacturing processes, and therefore in performance and application fields.

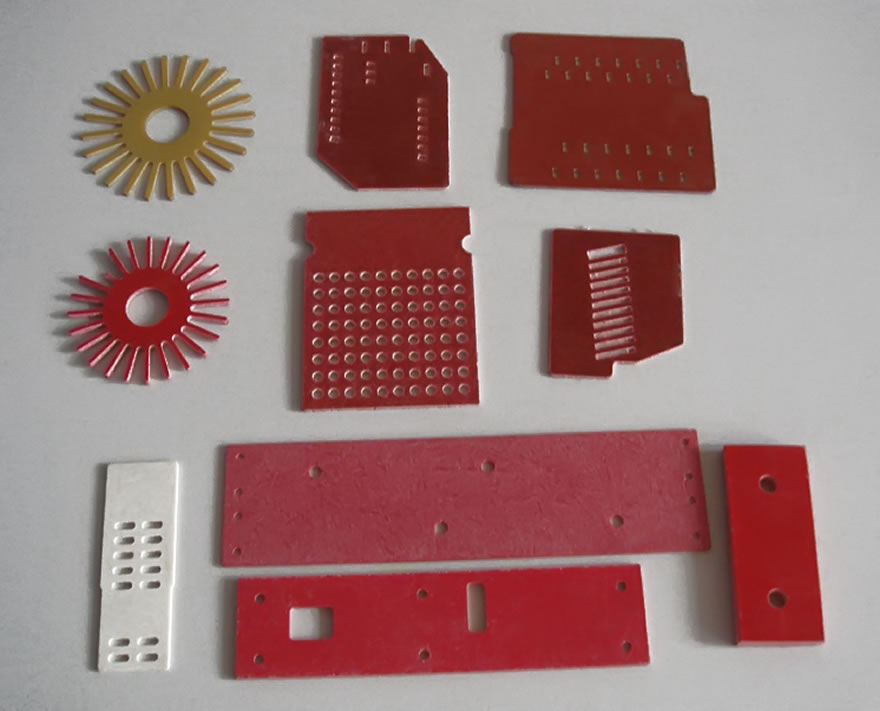

GPO-3 material sheets

G10 material sheets

1. Material Composition and Structural Differences

| Item | GPO-3 | G10 |

|---|---|---|

| Base reinforcement | Chopped strand fiberglass mat (CSM) | Woven fiberglass cloth |

| Resin system | Unsaturated polyester resin (UP) | Epoxy resin |

| Manufacturing process | Compression molding / SMC molding | Thermoset laminated sheet (heat-pressed laminates) |

| Appearance | Slightly rough, visible texture | Smooth, dense, high precision |

GPO-3 is more of a structural insulating material, while G10 is designed for high strength, high insulation, and precision applications.

2. Performance Differences

Mechanical Performance (G10 is significantly stronger)

| Property | GPO-3 | G10 |

|---|---|---|

| Flexural strength | 150–200 MPa | 350–480 MPa |

| Tensile strength | 100–150 MPa | 300–400 MPa |

| Impact strength | Medium | High |

| Dimensional stability | Medium | Excellent |

The mechanical strength of G10 is more than double that of GPO-3, suitable for high-stress and precision structures.

Electrical Performance

| Parameter | GPO-3 | G10 |

|---|---|---|

| Dielectric strength | 12–18 kV/mm | 20–25 kV/mm |

| Insulation resistance | High | Very high |

| Tracking resistance (CTI) | Very high (≥600V) | Medium to high (250–600V depending on grade) |

| Arc resistance | Excellent (>180 s) | High (>120 s) |

Key differences:

GPO-3 provides superior arc resistance (ideal for LV switchgear).

G10 provides higher dielectric strength (better for high-voltage insulation).

Thermal Performance

| Property | GPO-3 | G10 |

|---|---|---|

| Continuous thermal rating | 130°C (Class B) | 155°C (Class F), up to 180°C for modified grades |

| Thermal expansion | Higher | Lower (more stable) |

| Thermal decomposition temperature | Medium | Higher |

G10 offers much better heat stability, suitable for high-temperature and heavy-load environments.

Flame Retardancy

Both materials can reach UL94 V-0.

GPO-3: Naturally excellent flame retardancy + superior arc resistance

G10: Flame retardant depending on formulation (FR4 is the common flame-retardant epoxy)

GPO-3 is more suitable for arc-intensive, flame-critical environments.

Machinability

| Property | GPO-3 | G10 |

|---|---|---|

| CNC precision | Medium | High precision |

| Tool wear | Low | High (material is harder) |

| Cut edge quality | Rougher | Clean and smooth |

G10 is better for complex and precision-machined components, while GPO-3 is ideal for standard structural parts.

3. Application Comparison

GPO-3 Applications (mainly low-voltage power distribution)

LV switchgear barriers and partitions

Busbar supports, busbar holders

Distribution box insulation components

Transformer terminal boards

Arc-barrier and arc-proof components

Suitable for arc resistance, flame retardancy, and structural insulation in electrical equipment.

G10 Applications (high strength / high insulation)

Transformer slot wedges & insulation barriers

Motor insulation components

Precision structural parts

Electronic insulation parts

Aerospace and military components

High-temperature mechanical supports

Suitable for high mechanical strength, high dielectric performance, and thermal stability applications.

4. Summary: How to Choose?

| Requirement | Recommended Material |

|---|---|

| Very high mechanical strength (>300 MPa) | G10 |

| High-precision CNC machining | G10 |

| Superior arc resistance (>180 s) | GPO-3 |

| LV switchgear / busbar insulation supports | GPO-3 |

| High voltage / high insulation | G10 |

| Cost-sensitive projects | GPO-3 |

| Operating temperature above 130°C | G10 |

One-Sentence Summary

GPO-3 is ideal for structural insulation in power distribution systems, while G10 is the better choice for high-strength, high-insulation, and high-temperature precision components.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted