Motor Slot Insulation Selection Guide(DMD/NMN/AMA)

Motor Slot Insulation Selection Guide 1.Functions of Motor Slot Insulation Motor slot insulation is placed between ...

Motor Slot Insulation Selection Guide

1.Functions of Motor Slot Insulation

Motor slot insulation is placed between the stator core and the windings. It ensures safe operation under high temperature, electrical stress, and mechanical vibration.

Its main functions include:

Electrical isolation: Prevent turn-to-turn faults and ground insulation breakdown

Thermal protection: Withstand operating temperature and thermal shock

Mechanical protection: Resist pressure from windings during insertion and operation

Long-term reliability: Increase the lifespan of the overall insulation system

2. Common Types of Motor Slot Insulation Materials

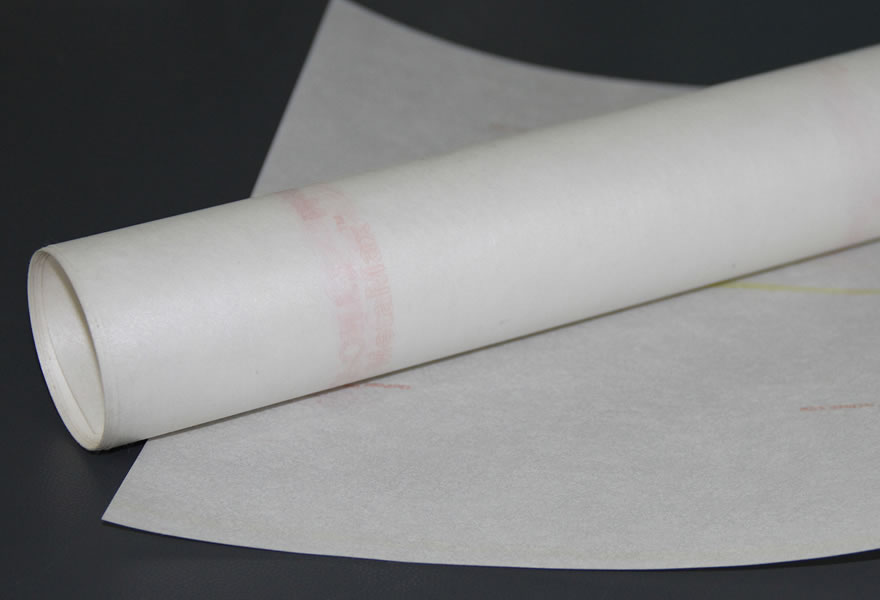

1) DMD Insulation Paper (Polyester Non-woven + Polyester Film)

Structure: D + M + D

Thermal class: Class B (130°C) / Class F (155°C)

Features: Soft, easy to form, cost-effective

Applications: Small and medium motors, standard industrial motors

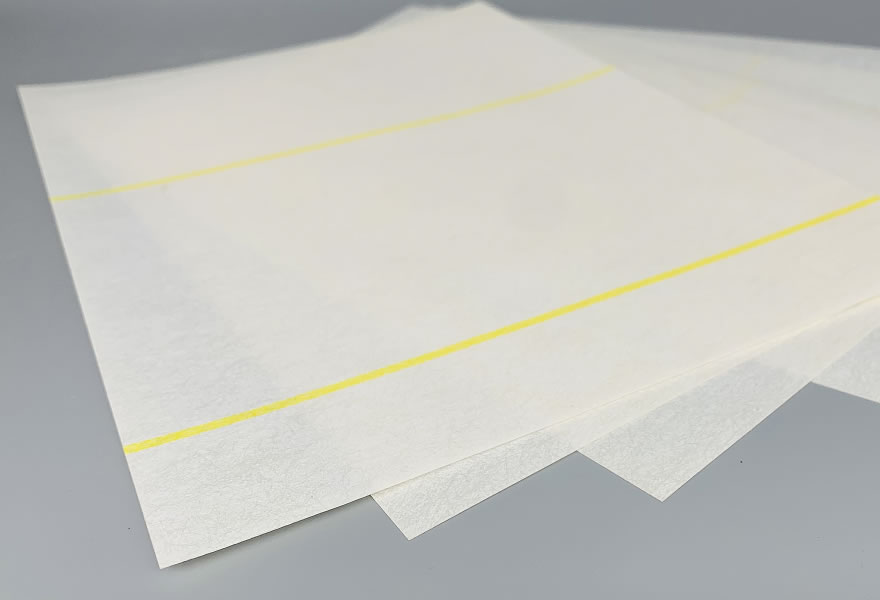

2) NMN Insulation Paper (Aramid Paper + Polyester Film)

Structure: N + M + N

Thermal class: Class F (155°C) / Class H (180°C)

Features: Excellent thermal shock resistance, high mechanical strength, strong bonding after varnishing

Applications: Medium and large motors, high-temperature motors, VPI motors

3) AMA Insulation Paper (Aramid Non-woven + Aramid Film)

Thermal class: Class H (180°C)

Features: Highest thermal stability, excellent aging resistance, ideal for high-voltage pulses

Applications: High-voltage motors, inverter-driven motors, traction motors

4) Polyester Film and Basic Insulation Paper

Thermal class: Class E (120°C)

Features: Low cost, suitable for simple motor structures

Applications: Small household motors, low-power motors

3. Key Factors for Selecting Slot Insulation Materials

1) Select According to Insulation Class

| Insulation Class | Max Temperature | Recommended Insulation |

|---|---|---|

| Class E (120°C) | Small motors | Polyester film, PET paper |

| Class B (130°C) | Standard motors | DMD (B-class) |

| Class F (155°C) | Industrial motors | F-class DMD / NMN |

| Class H (180°C) | High-temp motors | NMN (H-class), AMA |

2) Select Appropriate Thickness Based on Motor Size

| Motor Type | Recommended Thickness |

|---|---|

| Small motors | 0.13–0.20 mm |

| Industrial motors | 0.20–0.25 mm |

| Large / high-voltage motors | 0.30–0.35 mm |

3) Electrical Strength Requirements

Standard industrial motors: 6–12 kV

High-voltage motors: ≥15 kV

Inverter motors (PWM output): require high dielectric and corona resistance

→ Recommended NMN (H class) or AMA

4) Whether the Motor Uses Varnish Impregnation / VPI

For VPI Motors

Material must provide strong resin absorption and bonding

Recommended: NMN, AMA

For Non-VPI Motors

Flexibility and formability are more important

Recommended: DMD (B/F Class)

4. Recommended Selection for Typical Applications

1) General Industrial Motors (Most Common)

F-class DMD, 0.20–0.25 mm

2) High-Temperature Motors / Compressors / Blowers

NMN 155°C or NMN 180°C, 0.20–0.30 mm

3) High-Voltage or Large Motors

AMA or NMN (H Class), 0.30–0.35 mm

4) Inverter-Fed Motors (PWM Spike Voltage)

AMA H-class

Excellent corona resistance and partial discharge performance

5) Cost-Sensitive Motors

B-class DMD, 0.18–0.20 mm

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations