Laminated Wood in Oil-Immersed Transformers: Electrical Insulation and Mechanical Support

Laminated Wood in Oil-Immersed Transformers Laminated wood, also known as electrical laminated wood or insulation la...

Laminated Wood in Oil-Immersed Transformers

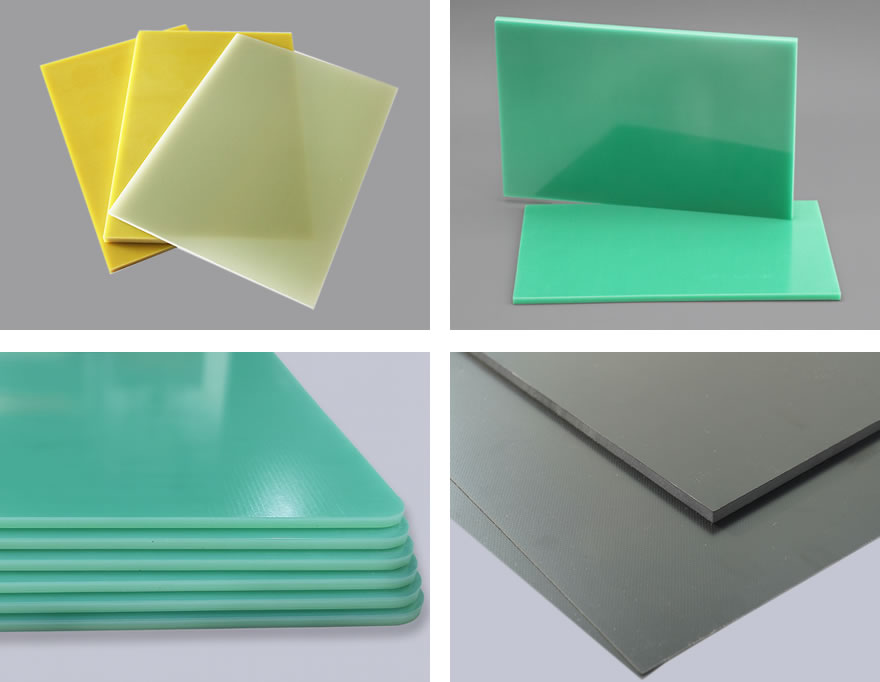

Laminated wood, also known as electrical laminated wood or insulation laminate, is a critical material used in oil-immersed transformers and instrument transformers. Its excellent electrical insulation, high mechanical strength, and customizable shapes make it ideal for supporting and isolating internal components. Laminated wood ensures the transformer operates safely and reliably under demanding conditions.

What is Laminated Wood?

Laminated wood is produced by impregnating high-quality birch wood veneers with insulating resin and then pressing them under heat. This process creates a dense, durable material that combines both mechanical strength and electrical insulation. Due to its versatility, laminated wood can be machined into various components such as:

Coil clamping plates

Support blocks

Insulating spacers

Core and coil supports

These components are widely used in oil-immersed transformers to maintain structural integrity and prevent electrical faults.

Manufacturing Process of Electrical Laminated Wood

The production of electrical laminated wood involves multiple precise steps:

Veneer Preparation: High-quality birch wood is sliced into thin sheets and dried.

Impregnation: Sheets are soaked in insulating resin through single or double impregnation.

Lamination: Sheets are stacked in cross-grain patterns to enhance mechanical strength.

Hot Pressing: The stack is pre-pressed and then heat-pressed under high pressure to form a solid laminate.

Machining: The laminated block is cut, drilled, and finished according to transformer component specifications.

This careful process ensures the laminated wood is strong, heat-resistant, oil-resistant, and dimensionally stable.

Key Roles of Laminated Wood in Oil-Immersed Transformers

Electrical Insulation

Even though transformers use insulating oil, certain structural parts such as coil frames, spacers, and supports require solid insulation. Laminated wood effectively isolates high-voltage and low-voltage regions, preventing:

Electrical breakdown

Partial discharge

Current leakage

This guarantees safe operation and long-term reliability.

Mechanical Support

Transformers experience strong electromagnetic forces during operation, which can cause coils to shift or deform. Laminated wood provides excellent:

Compressive and bending strength

Shear resistance

Structural stability

It keeps windings and components securely fixed, reducing vibration and mechanical stress.

Heat and Oil Resistance

Laminated wood is treated with insulating resins, giving it:

High thermal stability

Resistance to transformer oil corrosion

Long-term durability in harsh environments

This ensures consistent electrical and mechanical performance over time.

Environmental and Safety Benefits

As a renewable resource, laminated wood is environmentally friendly compared to synthetic insulation materials. Its reliable insulation properties also reduce the risk of electrical accidents, supporting safer transformer operation.

Easy Machining and Installation

Laminated wood is highly machinable and can be customized to precise transformer design requirements. This enables:

Fast assembly

On-site maintenance and replacement

Adaptation to complex structures

Its ease of use makes it a preferred material in transformer manufacturing.

Common Applications Inside Transformers

Coil clamping plates

Spacers and support blocks

Coil frame insulation

End winding support

Core and winding assembly components

Laminated wood is integral to almost every structural and insulating component of an oil-immersed transformer.

Conclusion

Laminated wood plays a crucial role in oil-immersed transformers by providing:

High electrical insulation

Strong mechanical support

Heat and oil resistance

Environmental friendliness

Ease of machining and installation

Its combination of properties makes it an indispensable material for transformer reliability and safety.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 03-03 2026G10 Fiberglass Density Standard

- 03-02 20262026 Global Epoxy Sheet Market Trends | FR4 & G10 Electrical Insulation Demand Growth

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers