Is a Cold punching sheet phenolic cotton cloth laminate or phenolic paper laminate?

Cold punching sheets are typically made of phenolic paperboard, not phenolic cloth. Phenolic paperboard, with its exc...

Cold punching sheets are typically made of phenolic paperboard, not phenolic cloth. Phenolic paperboard, with its excellent electrical properties, mechanical strength, and processability, is a more suitable material for cold punching sheets.

Basic Concepts of Cold Punching Sheets

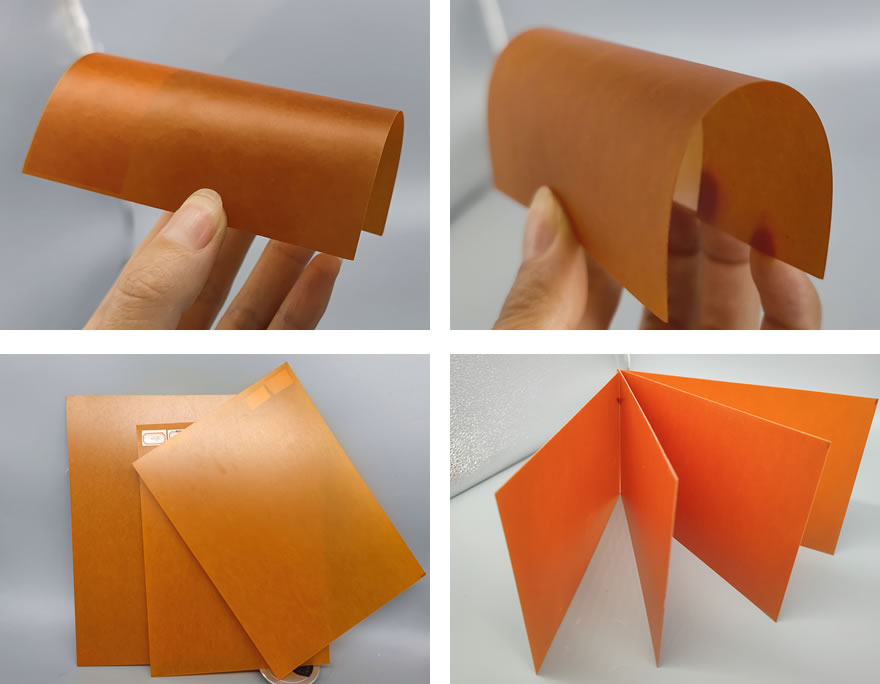

Cold punching sheets are laminated sheets made by impregnating bleached wood pulp paper with phenolic resin and hot pressing at high temperatures. They exhibit excellent mechanical and dielectric properties. This material can be punched and sheared stably at room temperature and has a temperature resistance range of 150°C to 300°C, making it suitable for humid environments and transformer oil applications. As a core insulation material for electronic and electrical products, its typical applications include FPC reinforcement, PCB test fixtures, and carbon film printed circuit boards.

Why Cold Punching Sheets Are Usually Made of Phenolic Paperboard

As an electrical insulation material, cold punching sheets must meet certain electrical performance, mechanical strength, and processability requirements. Phenolic paperboard excels in these areas, especially its excellent processability and low cost, making it an ideal choice for cold punching sheets. Phenolic paperboard also offers excellent oil, acid, and water resistance, meeting the requirements for cold punching sheets in various environments. II. Comparison of the Characteristics of Phenolic Cloth Board and Phenolic Paperboard

1. Phenolic Cloth Board: Phenolic cloth board is made from fiberglass cloth, impregnated with phenolic resin, and then hot-pressed. It has high mechanical strength and heat resistance, but is difficult to process and relatively expensive.

2. Phenolic Paperboard: Phenolic paperboard is made from wood cellulose paper, also impregnated with phenolic resin, and then hot-pressed. Phenolic paperboard has excellent electrical properties, mechanical strength, and processability, and is relatively low in cost, making it widely used in electrical insulation.

Comparison Between Phenolic Cotton Cloth Laminate and Phenolic Paper Laminate

| Item | Phenolic Cotton Cloth Laminate | Phenolic Paper Laminate (Cold-punched board) |

| Base Material | Cotton fabric + phenolic resin | Electrical paper + phenolic resin |

| Mechanical Strength | High, excellent impact resistance, wear resistance, and bending strength | Moderate, suitable for light-load structural parts |

| Processing Method | Requires machining (turning, milling, drilling, etc.) | Can be cold-punched into shape, high processing efficiency |

| Electrical Properties | Medium insulation properties, lower than paper laminate | Excellent electrical insulation, high dielectric strength |

| Heat Resistance | Good, stable under higher temperatures | Average, properties decline under moisture |

| Wear Resistance | Excellent, can replace some metal parts | Poor, not suitable for friction parts |

| Main Advantages | High strength, good toughness, wear resistance, heat resistance | Excellent electrical properties, low cost, suitable for stamping |

| Main Disadvantages | Electrical properties are inferior to paper laminate, higher processing cost | Lower mechanical strength, poor wear resistance |

| Typical Applications | Gears, bearing cages, friction plates, mechanical structural parts, wear-resistant insulating components | Gaskets, insulation spacers, stamped parts for switchgear/transformers, motor insulation parts |

Recommendations for Selecting Cold-Punched Board

When selecting cold-punched board, in addition to considering the material (phenolic paperboard or phenolic cloth board), the following factors should also be considered:

1. Electrical Performance: Select the appropriate electrical performance level based on the specific application scenario.

2. Mechanical Strength: Ensure that the selected cold-punched board has sufficient mechanical strength to support equipment operation.

3. Processing Performance: Consider factors such as the ease of processing and yield of the cold-punched board. 4. Cost: Choose a product with the best value for money, while meeting performance requirements.

In summary, cold-punched panels are typically made of phenolic paperboard rather than phenolic cloth. When choosing a cold-punched panel, consider factors such as electrical performance, mechanical strength, processing performance, and cost to select the best product for your needs.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations