Introduction to G11 Epoxy Sheet and Selection Guide

Introduction to G11 Epoxy Sheet G11 epoxy glass fiber sheet is a high-performance insulation material made of glass ...

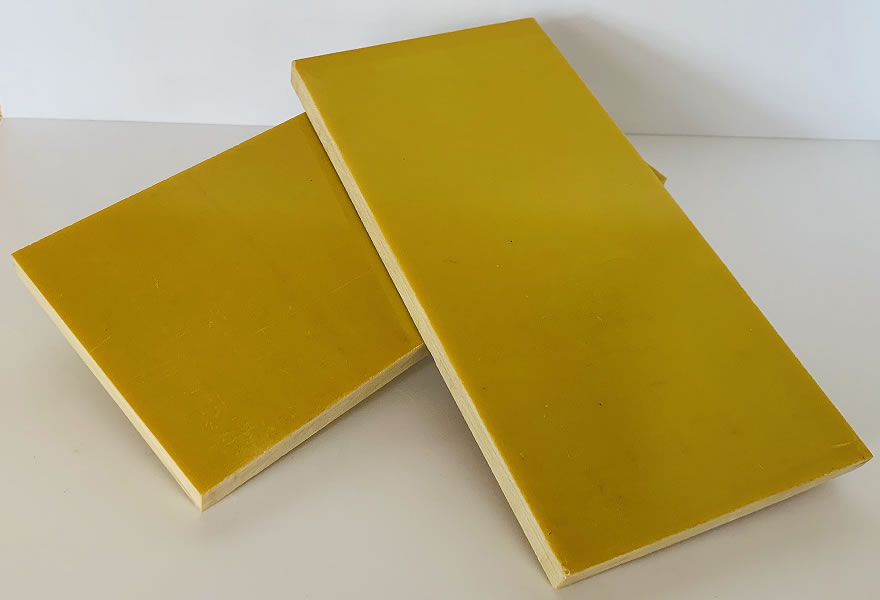

Introduction to G11 Epoxy Sheet

G11 epoxy glass fiber sheet is a high-performance insulation material made of glass fiber cloth as reinforcement and epoxy resin as the matrix, laminated under high temperature and pressure. It belongs to the family of epoxy glass fiber laminates and is considered an upgraded version of FR4.

Key Features:

Excellent high-temperature resistance: Compared with G10 and FR4, G11 can operate continuously at 180℃–200℃, with outstanding thermal stability.

High mechanical strength: Maintains excellent flexural and impact strength even under high temperatures.

Superior electrical insulation: High dielectric strength, suitable for electrical insulation applications.

Moisture and chemical resistance: Performs stably in humid or chemically corrosive environments.

Dimensional stability: Low thermal expansion, ideal for precision electrical equipment.

Typical Applications:

Insulation components for high-temperature motors and electrical devices

Insulating partitions and support structures in dry-type transformers

High-temperature electrical switches and controllers

Aerospace and military electronic insulation components

Selection Guide for G11 Epoxy Sheet

The following aspects should be considered when selecting G11:

Operating Temperature

If < 130℃ → FR4 or G10 is sufficient.

If 155℃–200℃ for long-term use → G11 is recommended.

Mechanical Strength

For heavy load-bearing or structural support parts → choose G11.

For general insulation purposes → G10 or FR4 is acceptable.

Electrical Requirements

For high insulation and dielectric strength (e.g., high-voltage equipment, transformers) → G11 is more reliable.

Service Environment

In humid or chemically corrosive environments → G11 is superior to FR4.

Cost Consideration

G11 offers the best performance but comes at a higher cost. If performance requirements are not extreme, FR4 or G10 can be a more economical choice.

Comparison Table: FR4 / G10 / G11

| Material | Long-term Operating Temp. | Mechanical Strength | Electrical Properties | Moisture / Chemical Resistance | Cost Level | Typical Applications |

|---|---|---|---|---|---|---|

| FR4 | ~130℃ | High | Excellent | Good | ★ (Lowest) | PCB boards, general electrical insulation |

| G10 | ~140℃ | High (better than FR4) | Excellent | Good | ★★ (Medium) | Electrical/motor insulation structures |

| G11 | 155℃–200℃ | Very high (retains strength at high temp) | Superior (stable under high voltage/frequency) | Excellent | ★★★ (Highest) | Dry-type transformer insulation, high-temp motors, aerospace, defense electronics |

Summary:

G11 epoxy sheet is a high-performance, high-temperature resistant insulation material widely used in electrical insulation and structural applications. Selection should be based on operating temperature, mechanical strength, electrical performance, and cost:

Standard applications → FR4 / G10

High-temperature & high-strength applications → G11

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted