In-depth analysis of the five major insulating laminates

Overview of Insulating Laminates Insulating laminates are known for their excellent performance among many insulatin...

Overview of Insulating Laminates

Insulating laminates are known for their excellent performance among many insulating materials. By deeply analyzing several common insulating laminate materials, we can find the best choice for our needs. Laminates are widely used in motors, electrical equipment, and PCB manufacturing due to their excellent electrical insulation, mechanical strength, and chemical resistance.

Five major insulating laminates

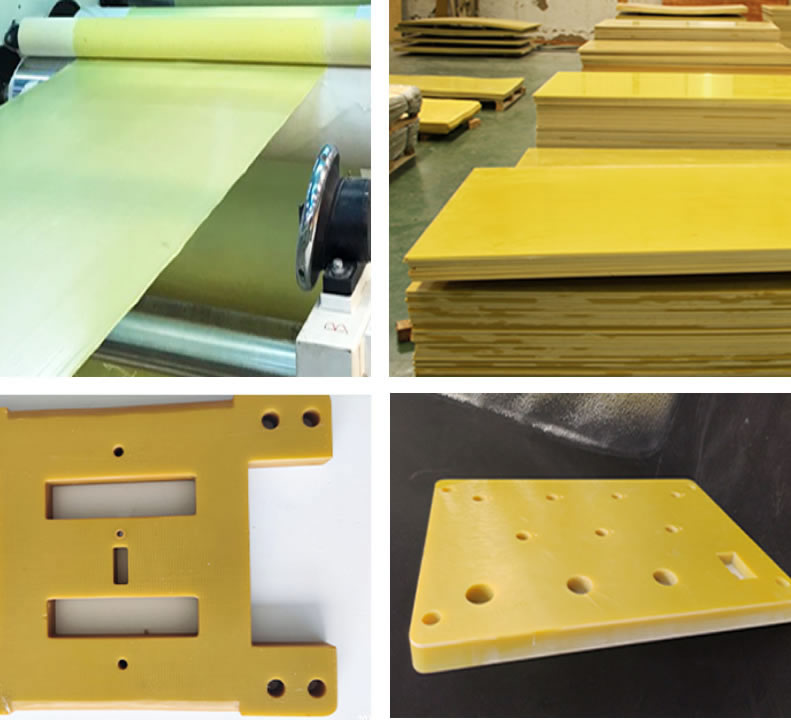

[3240 epoxy board]

Among insulating materials, 3240 epoxy laminates perform well in applications such as transformer oil-immersed environments and PCB drilling pads due to their excellent electrical insulation, mechanical strength, and chemical resistance.

Brand: 3240, EPGC201; Full name: Epoxy laminated glass cloth board; Color: usually yellow, aqua, and other options such as black are also available; Size: 1000mm×2000mm, 1220mm×2440mm, and other specifications are available; Thickness: ranging from 0.5mm to 100mm to meet different needs.

Features: Made of glass fiber cloth and epoxy resin, it has excellent electrical insulation, mechanical strength and chemical resistance. Its temperature resistance reaches F grade (155℃), ensuring the stability of mechanical properties under high temperature environment. Application: Suitable for the manufacture of insulating structural parts of motors and electrical equipment, such as oil-immersed environment of transformers, PCB drilling pads, distribution boxes and mold splints.

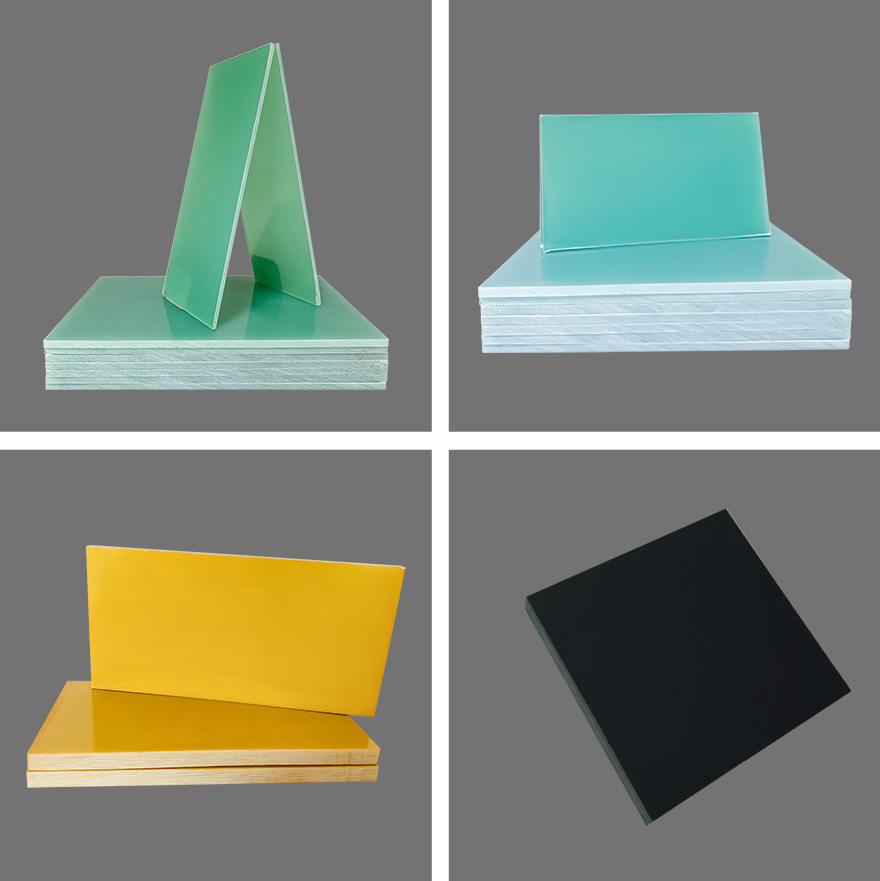

[FR4 fiberglass board]

FR4 fiberglass board combines glass fiber and epoxy resin, has good mechanical and dielectric properties, and is an ideal material for PCB manufacturing.

Brand: FR4, EPGC202; Full name: Epoxy glass fiber cloth base laminated copper clad plate; Color: Often presented in yellow, green, black, etc.; Size: Provide a variety of size options such as 1220mm×2440mm, 1000mm×2000mm; Thickness: The thickness ranges from 0.1mm to 50mm to meet different processing needs.

Features: It uses glass fiber cloth and epoxy resin for fine lamination, combined with copper cladding process, giving it excellent mechanical properties, dielectric properties, heat resistance and moisture resistance. Its temperature resistance grade also reaches F grade (155℃), ensuring that it can still maintain high mechanical strength in high temperature environment. Application: It is widely used in the field of PCB manufacturing, such as as a substrate for multi-layer printed circuit boards, and insulating structural parts in motors and electrical equipment. At the same time, it is also suitable for high-demand application scenarios such as FPC reinforcement boards and tin furnace high-temperature resistant boards.

[Bakelite]

The hardness, wear resistance and high strength of phenolic laminated paperboard make it an ideal insulating material in motor and transformer oil environments.

Brand: such as PFCP201, PFCP202, PFCP203 and PFCP206; Full name: phenolic laminated paperboard; Color: mainly orange and black; Size: 1000mm×2000mm, 1220mm×2440mm and other sizes are available; Thickness: ranging from 1mm to 50mm to meet different processing needs.

Features: Made of insulating impregnated paper and phenolic resin, it exhibits high mechanical strength, excellent insulation and heat resistance. Its surface is hard and wear-resistant, and it is not easy to be scratched. Application: It plays the role of high-demand insulation structural parts in motors and electrical equipment, such as transformer oil environment. At the same time, it is also widely used in many fields such as PCB drilling pads, distribution boxes, mold splints, etc.

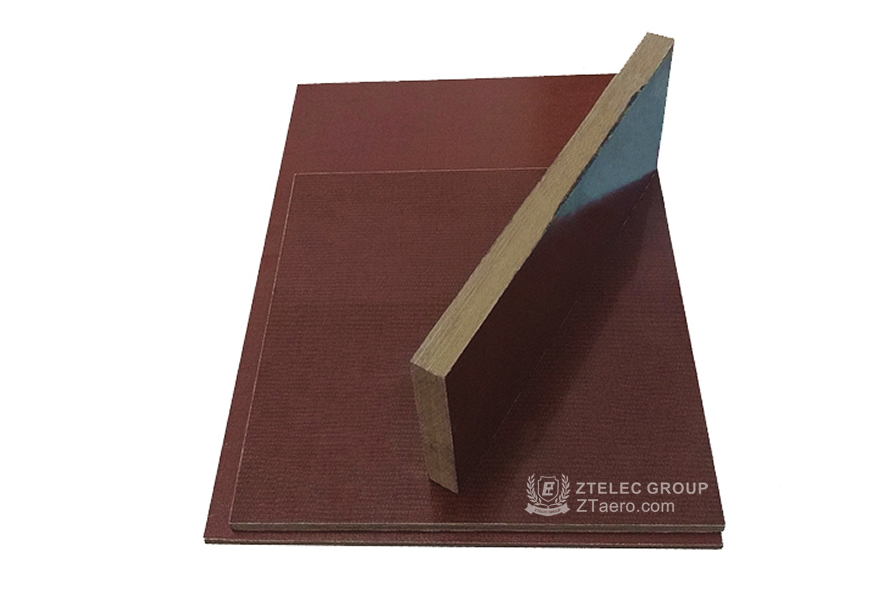

[Phenolic cotton cloth board]

Phenolic cotton cloth laminate is widely used to make insulating structural parts of electrical appliances due to its excellent electrical insulation and mechanical strength.

Brand: 3722, 3723, 3724, 3725, etc.; Full name: Phenolic cotton cloth laminate; Color: Mainly reddish brown and black; Size: Provide 1000mm×2000mm, 1220mm×2440mm and other sizes; Thickness: The thickness ranges from 1mm to 50mm to meet diversified processing needs.

Features: Made of cotton cloth and phenolic resin, it has excellent electrical insulation performance and mechanical strength, and also exhibits good heat and moisture resistance. Application: Widely used in the production of insulating structural parts of motors and electrical equipment, such as switches, sockets, and electrical insulation carbon film printed circuit boards.

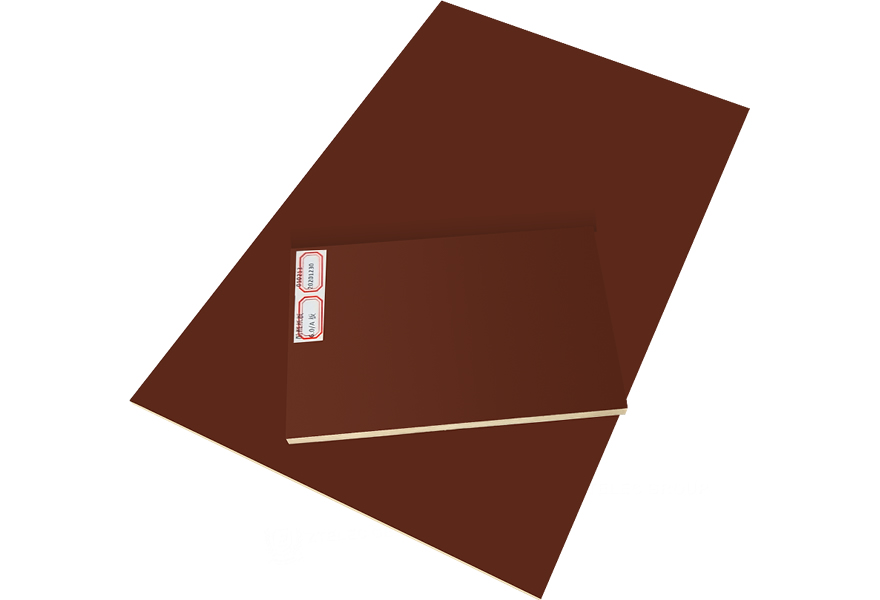

[Phenolic paperboard]

Phenolic paperboard is widely used in the production of insulating parts of electrical equipment due to its insulation performance and heat resistance.

Brand: 3722, 3723, 3724, 3725, etc.; Full name: phenolic cotton cloth laminate; Color: mainly red brown and black; Size: 1000mm×2000mm, 1220mm×2440mm and other specifications are available; Thickness: The thickness ranges from 1mm to 50mm to meet different processing requirements.

Features: Made of cotton cloth and phenolic resin, it has excellent electrical insulation performance and mechanical strength, and also exhibits excellent heat and moisture resistance. Application: Widely used in the production of insulating structural parts of motors and electrical equipment, such as switches, sockets, and electrical insulation carbon film printed circuit boards.

By deeply analyzing these five insulating laminates, you can easily find the best choice for your specific needs. Whether it is motors, electrical equipment or PCB manufacturing, each laminate has its unique advantages.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted