How to Select Crepe Paper for Oil-Immersed Transformers

I. Definition and Characteristics of Crepe Paper Crepe paper is a flexible insulating material made from high-purity...

I. Definition and Characteristics of Crepe Paper

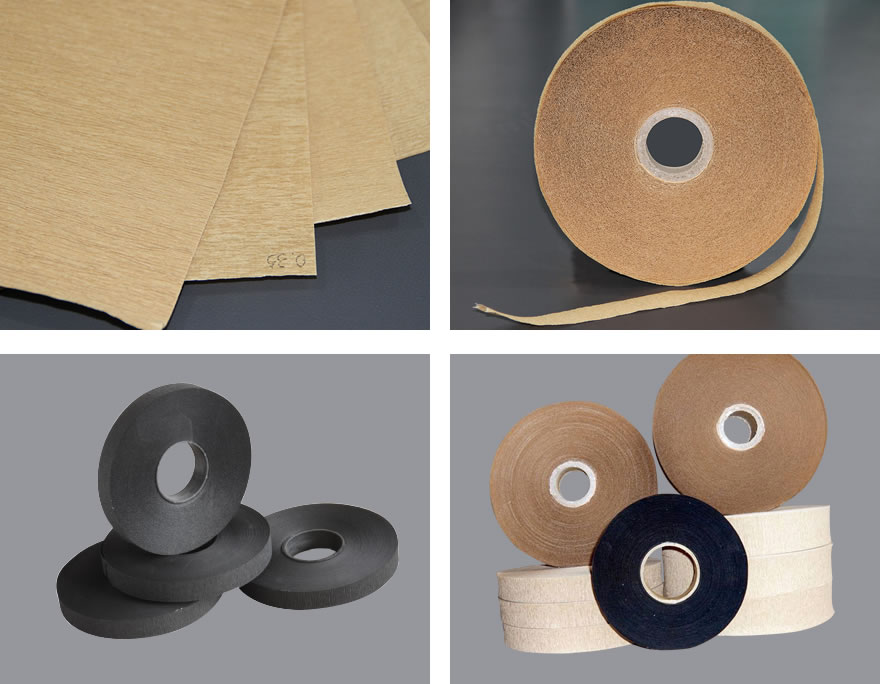

Crepe paper is a flexible insulating material made from high-purity electrical insulation paper that has been mechanically creped.

Its main characteristics include:

High flexibility and elasticity — closely adheres to conductor surfaces;

Excellent oil absorption and high dielectric strength when impregnated with oil;

Good oil and heat resistance with stable insulation performance;

Ability to relieve mechanical stress caused by thermal expansion and contraction.

Therefore, crepe paper is one of the most widely used wrapping insulation materials in oil-immersed transformers.

II. Main Functions of Crepe Paper in Oil-Immersed Transformers

| Function Category | Specific Role | Description |

|---|---|---|

| 1. Conductor Wrapping Insulation | Provides the primary insulation layer around conductors | Replaces smooth paper; more flexible and less prone to cracking |

| 2. Turn-to-Turn / Layer-to-Layer Insulation | Increases dielectric distance between wires | Improves insulation and voltage withstand performance |

| 3. Lead and End Insulation | Provides mechanical protection and oil resistance | Prevents partial discharge and aging at winding ends |

| 4. Electric Field Smoothing | Balances the electric field at winding ends | Enhances local insulation safety margin |

| 5. Oil Flow Path Formation | Crepe structure promotes oil circulation and heat dissipation | Improves cooling and oil impregnation efficiency |

In summary:Crepe paper = flexible insulation + oil channel + electric-field buffer.

III. Key Parameters for Crepe Paper Selection

| Parameter | Technical Requirement | Description |

|---|---|---|

| Base Paper | 100% high-grade unbleached kraft electrical paper | Ensures purity, oil resistance, and dielectric stability |

| Basis Weight (g/m²) | 60–120 (common range) | Thicker paper offers greater mechanical strength |

| Crepe Stretch Ratio | 10–35% | Determines flexibility and wrapping conformity |

| Oil Absorption | ≥300% | Ensures uniform oil impregnation |

| Dielectric Strength (in oil) | ≥35–40 kV/mm | For high-voltage applications, ≥40 kV/mm is recommended |

| Thermal Class | Class A (105 °C) standard; up to Class H (180 °C) for special grades | Choose according to operating temperature |

| Appearance | Free from spots, holes, or cracks | Guarantees uniform insulation quality |

IV. Selection Recommendations by Transformer Section

| Application Area | Recommended Type | Basis Weight (g/m²) | Stretch Ratio | Key Features |

|---|---|---|---|---|

| Low-Voltage Winding Wrapping | Fine Crepe Paper | 60–70 | 10–20% | Soft, flexible, prevents sharp bends |

| High-Voltage Layer / Turn Insulation | Medium Crepe Paper | 80–90 | 15–25% | Balanced dielectric and mechanical strength |

| Leads & End Reinforcement | Heavy Crepe Paper or Aromatic Modified Crepe Paper | 100–130 | 25–35% | Excellent mechanical protection and heat resistance |

| EHV Transformer End Sections | Polyimide Composite Crepe Paper | ≥100 | 20–25% | Thermal endurance 120–155 °C for critical zones |

V. Selection Reference by Voltage Level

| Voltage Level | Recommended Paper Type | Thermal Class | Typical Application |

|---|---|---|---|

| ≤35 kV | Standard Class A Crepe Paper | 105 °C | Conventional oil-immersed distribution transformers |

| 66–110 kV | Modified Class A Crepe Paper | 105–120 °C | High-voltage windings |

| 220 kV | Aromatic Modified Crepe Paper | 120 °C | Lead wrapping and end insulation |

| ≥500 kV | PI/PTFE Composite Crepe Paper | ≥155 °C | Extra-high-voltage and extreme-temperature zones |

VI. Quality and Testing Standards

Applicable Standards:

GB/T 5643 – Electrical Crepe Paper

IEC 60554 – Cellulosic Papers for Electrical Purposes

| Test Item | Standard Requirement |

|---|---|

| Moisture Content | ≤7% |

| Tensile Strength | ≥40 N/15 mm |

| Oil Absorption | ≥300% |

| Dielectric Strength (in oil) | ≥35 kV/mm |

| Crepe Uniformity | No visible variation in thickness |

| Powdering (surface dust) | ≤0.05 g/m² |

| Thermal Aging (120 °C × 96 h) | Property degradation ≤10% |

VII. Storage and Handling Guidelines

Storage: Keep in a dry, ventilated environment, humidity ≤60%, avoid direct sunlight.

Before Use: Balance moisture for at least 24 h in the transformer workshop, then vacuum-dry.

Long-Term Storage: Seal against moisture; if stored >6 months, re-dry before use.

During Wrapping: Maintain even tension, avoid tearing or powdering.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations