G11 Epoxy Sheet in High-Voltage Switchgear | Applications & Installation Guide

1. Introduction to G11 Material G11 epoxy glass fiber laminate (Epoxy Glass Cloth Laminate G11) is produced from alk...

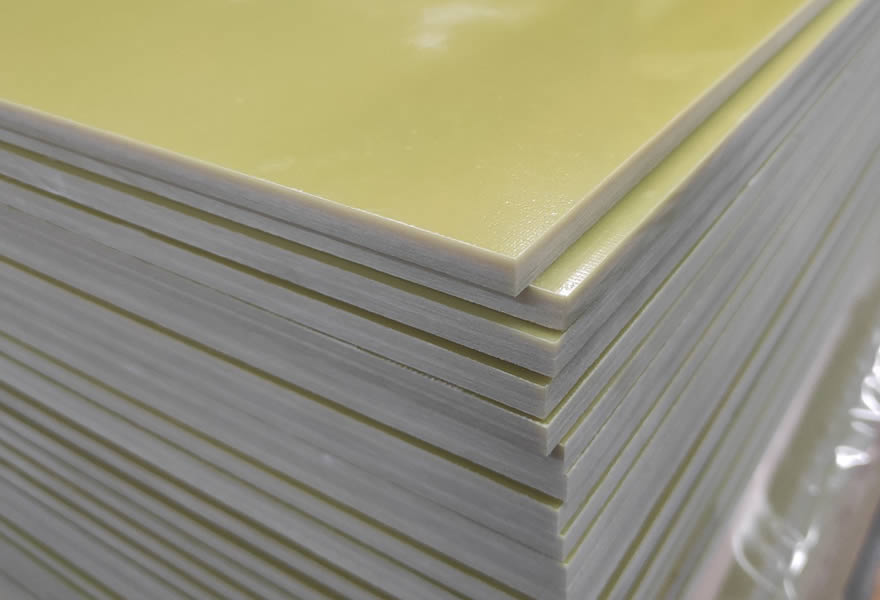

1. Introduction to G11 Material

G11 epoxy glass fiber laminate (Epoxy Glass Cloth Laminate G11) is produced from alkali-free fiberglass cloth impregnated with epoxy resin and cured under high temperature and pressure. It features H-class thermal resistance (180°C), high mechanical strength, excellent electrical insulation properties, and outstanding dimensional stability. It is widely used in high-voltage electrical equipment as structural support components, insulation partitions, and insulating spacers.

2. Main Applications of G11 in High-Voltage Switchgear

Phase Barriers

Used between busbar compartments, circuit breaker compartments, and adjacent phases.

Prevents arc propagation and enhances the dielectric strength of the switchgear.

Insulation Support Components

Commonly used as busbar supporting blocks and conductor insulating brackets.

Capable of withstanding continuous thermal and electrical stress without deformation.

Cable Fixing and Reinforcement Plates

Applied in the cable compartment or low-voltage chamber to support and secure cables.

Arc Isolation and Protective Shields

Installed between compartments to constrain internal arc faults and improve safety.

Operating Mechanism Components

Used in load switch mechanisms, isolators, and interlock systems as insulating pads, sliders, and support plates.

3. Technical Advantages of Using G11

| Property | Advantage |

|---|---|

| Thermal Resistance | 180°C, suitable for long-term operation under heavy thermal load |

| Mechanical Strength | High flexural strength, resistant to cracking under stress |

| Electrical Performance | High dielectric strength and insulation resistance |

| Low Water Absorption | Stable insulation performance even in humid environments |

| Dimensional Stability | Maintains shape accuracy, ideal for precision electrical assemblies |

4. Installation Methods of G11 in Switchgear

Cutting and Machining

CNC, milling, or laser cutting is recommended.

Edges must be smooth to avoid partial discharge.

Chamfering is recommended after machining.

Mounting Methods

(1) Bolt Fixing

Use galvanized or stainless-steel bolts with insulation washers.

Hole diameter should be 0.5–1 mm larger than bolt size.

Avoid excessive torque to prevent cracking.

(2) Insulation Support Posts

G11 plates can be mounted with epoxy insulator posts or sleeves.

Widely used for busbar support and partition mounting.

(3) Rail or Slot Fixing

Switchgear structures may include metal rails for sliding installation.Provides easy disassembly and maintenance.

Electrical Clearance and Creepage Requirements

Rated Voltage Minimum Clearance Minimum Creepage Distance

12 kV ≥ 125 mm ≥ 20 mm/kV

24 kV ≥ 240 mm ≥ 25 mm/kV

(Refer to IEC 62271 and national standards for actual assembly.)

Surface Treatment and Cleaning

Clean with anhydrous alcohol before installation.

Prevent oil, moisture, or dust from reducing insulation performance.

Post-Installation Inspection

Ensure moderate tightness of bolts.

Check for cracks, scratches, or edge defects.

Confirm that clearances and grounding requirements are met.

Make sure no unintended contact with live components exists.

5.Common Issues and Solutions

Edge Cracks

Cause: Blunt cutting tools or excessive tightening torque

Solution: Use sharp tools and reduce torque; chamfer edges

Moisture Affecting Insulation

Solution: Improve sealing and keep cabinet dry; use moisture-resistant G11 grades if necessary

Misaligned Bolt Holes

Solution: Ensure CNC precision machining and pre-check hole positions with jigs

6. Conclusion

G11 is a highly reliable structural insulation material for high-voltage switchgear thanks to its excellent insulation, strong mechanical strength, high thermal resistance, and stable performance. Proper machining and installation ensure long-term electrical safety and mechanical stability of the switchgear.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations