G11 epoxy sheet, G10, FR4 difference and selection

Differences Between G11 Epoxy Sheet, G10, and FR4 Comparison Item G10 FR4 G11 Base Material G...

Differences Between G11 Epoxy Sheet, G10, and FR4

| Comparison Item | G10 | FR4 | G11 |

|---|---|---|---|

| Base Material | Glass fiber cloth + epoxy resin | Glass fiber cloth + epoxy resin (flame-retardant type) | Glass fiber cloth + high heat-resistant epoxy resin |

| Heat Resistance Class | Class B (≈130℃) | Class B (≈130℃) | Class H (≈180℃) |

| Mechanical Strength | High strength, good toughness | Relatively high strength | Similar to G10, but retains strength much better at high temperatures |

| Electrical Properties | Stable insulation in dry and humid conditions | Good insulation, widely used in PCB | Excellent insulation, especially under high temperature and humidity |

| Flame Retardancy | Usually non-flame-retardant | UL94 V-0 flame-retardant | Available in both flame-retardant and non-flame-retardant grades (more flexible than G10) |

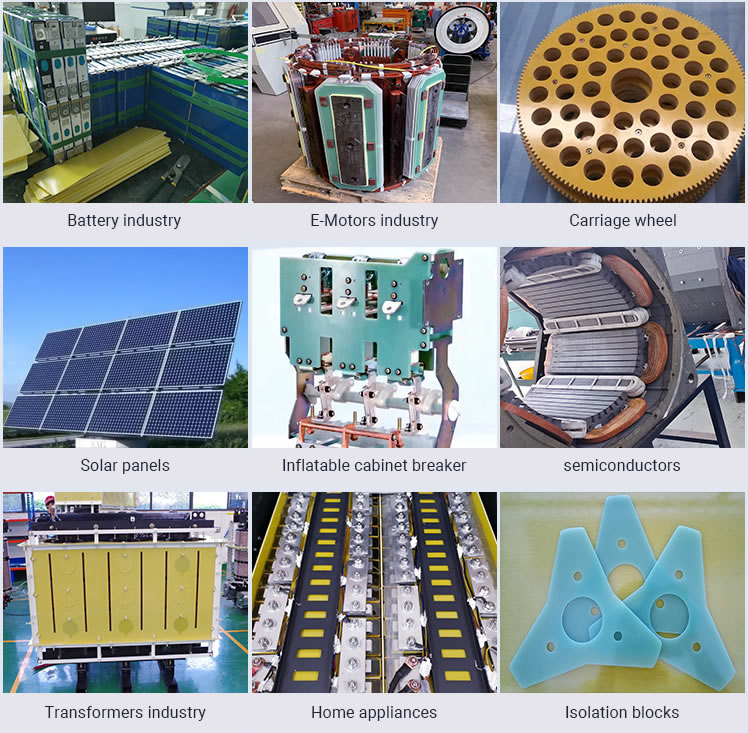

| Typical Applications | Motor insulation parts, transformer insulation, mechanical structural parts | Printed circuit boards (PCBs), general electrical insulation components | High-temperature motors, generators, transformers, high-voltage switchgear, heat-resistant structural parts |

| Key Features | High strength but non-flame-retardant | Flame-retardant, suitable for PCB | Upgraded version of G10 with superior heat resistance |

FR4 → Suitable for PCB and general electrical insulation; flame retardancy is the main advantage.

G10 → High strength but non-flame-retardant, commonly used in electrical and mechanical insulation parts.

G11 → An upgraded version of G10 with significantly improved heat resistance (up to 180℃), ideal for high-temperature electrical and mechanical applications.

Selection Guide for G11, G10, and FR4 Epoxy Sheets

Quick Decision Rule

≥150–180℃ continuous operation or strength required at high temperatures → G11

Up to ~130℃, high strength needed but flame retardancy not required → G10

Flame retardancy (UL94 V-0) or PCB/general insulation required → FR4 (or high Tg FR4)

Application-Based Selection

1) Transformers (Dry-type / Oil-immersed)

End rings, spacers, support blocks:

Dry-type, hot spots ≥155℃ → G11 1.0–10 mm (end rings typically 3–6 mm). Excellent dimensional stability at high temperatures.

Oil-immersed, ≤130℃ → G10 1.0–8 mm; use FR4 if flame-retardancy is required.

Creepage / humid environments: G11 or G10 preferred (better insulation stability in moist conditions).

Note: For large parts, chamfer or use rounded corners to reduce stress; degreasing/cleaning is recommended after machining for oil-immersed parts.

2) Motors / Generators (Insulation barriers, slot wedges, end supports)

F/H-class insulation, frequent thermal shocks → G11 0.8–3 mm (slot wedges usually 1.0–2.0 mm).

Medium temperature (B/F-class) → G10 0.8–3 mm; if flame-retardant required near wiring → FR4.

Highlight: G11 retains mechanical strength much better than G10/FR4 at >150℃, suitable for end supports in high-speed machines.

3) Switchgear / Control Cabinets (Insulation barriers, busbar supports, spacers)

High cabinet temperature rise, high current density → G11 2–10 mm (busbar supports typically 3–8 mm).

General distribution panels, balancing cost vs flame retardancy → FR4 2–8 mm.

Heavy mechanical loads / tightening torque → G10 or G11; use larger washers or countersunk holes around fasteners.

4) PCB / Electronics

Circuit boards → FR4 (standard Tg or high Tg 170 grade).

Clamping / structural insulation parts near heat sources → G11 1–4 mm; medium temperature → G10.

Note: If close to heating components and flame-retardancy is required → choose high Tg FR4 or flame-retardant G11.

5) New Energy Battery Packs / Energy Storage

High cavity temperature, thermal runaway risk → G11 1–3 mm; offers heat resistance and strength.

Normal temperature, lightweight priority → FR4 0.8–2 mm (with flame retardancy); for load-bearing parts → G10 or G11.

Engineering Comparison

| Property | FR4 | G10 | G11 |

|---|---|---|---|

| Continuous Operating Temp. | ~130℃ (higher with high Tg FR4) | ~130℃ | ~155–180℃, more stable |

| Strength Retention at High Temp. | Medium | Medium–High | High |

| Flame Retardancy | UL94 V-0 standard | Usually non-flame-retardant | Flame-retardant or non-FR options available |

| Moisture/Heat Stability | Good | Good | Excellent |

| Machinability | Easy | Easy | Slightly harder, requires good tools |

| Cost (relative) | Low–Medium | Medium | Medium–High |

Thickness & Structural Guidelines

0.8–1.5 mm → Barriers, shields, slot wedges (G11/G10/FR4 depending on conditions).

2–4 mm → End rings, supports, busbar spacers (medium mechanical load).

5–10 mm → Heavy load supports, base insulation pads (prefer G10 or G11).

Fastener zones → Hole ≥ 1.2 × thickness; edge distance ≥ 2 × thickness; chamfer 0.3–0.5 mm.

Design / Machining Notes

Thermal environment: For >150℃ continuous operation, G11 is the safe choice; FR4 weakens more under high heat/humidity.

Flame retardancy compliance: For cabinets, vehicles, energy storage → select V-0 grade (FR4 or flame-retardant G11).

Electrical creepage / clearance: In HV systems, choose G11/G10, increase thickness in humid areas, add ventilation slots.

Machining: Use carbide tools, apply multiple light passes; round corners and chamfer edges.

Surface treatment: For bonding/potting, first sand → clean → degrease (IPA/acetone).

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations