G11 Epoxy Laminates for Generator Slot Wedges

1. Overview of G11 Epoxy Laminate G11 epoxy laminate sheet is manufactured from woven fiberglass cloth and high-tem...

1. Overview of G11 Epoxy Laminate

G11 epoxy laminate sheet is manufactured from woven fiberglass cloth and high-temperature epoxy resin, laminated under high heat and pressure.

It belongs to NEMA G11 insulation grade and is widely used in generators due to its:

H-class thermal resistance (180–200°C)

High mechanical strength at both room and elevated temperatures

Excellent dielectric properties

Low moisture absorption and dimensional stability

These characteristics make G11 an ideal material for generator slot wedges and slot insulation systems.

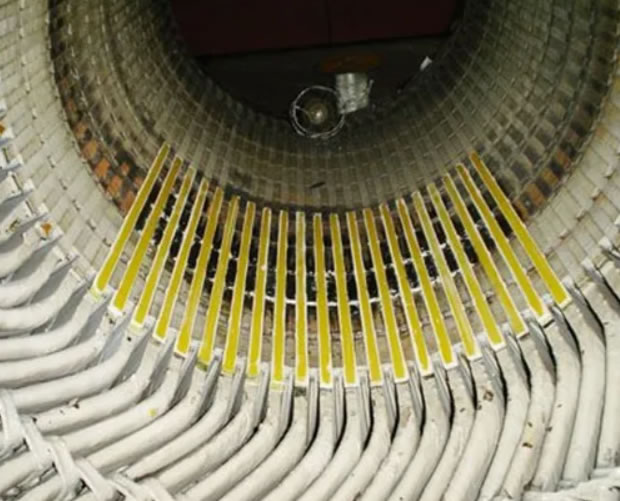

2. Application of G11 in Generator Slot Wedges

1) Stator Slot Wedges

In a generator stator, slot wedges secure the coils inside the slots and resist electromagnetic forces during operation.

Why G11 is preferred for slot wedges:

Does not soften or deform at high temperatures

High bending and compressive strength

Superior dielectric strength ensures insulation reliability

Moisture-resistant and chemically stable

Long-term dimensional stability and long service life

2) Slot Bottom and Slot Side Insulation

G11 is also used for:

Slot bottom liners

Slot side insulation shims

Coil support components

End winding support insulation parts

Its strength and thermal resistance make it suitable for high-performance generator insulation systems.

3. Selection Guide for G11 Slot Wedges

1) Select by generator insulation class

| Generator Class | Recommended Material |

|---|---|

| F-class (155°C) | G10 / FR4 or G11 |

| H-class (180°C) | G11 strongly recommended |

| VFD-driven, wind power, high-temperature machines | G11 required |

2) Thickness and Dimensions

Common thickness: 0.8–6 mm

Heavy-duty structural parts: 8–12 mm

Width: 10–80 mm

Length: 500–2000 mm (Typical: 1000 mm)

Tolerances:

Thickness: ±0.05–0.10 mm

Width: ±0.10 mm

Length: ±1 mm

Straightness: ≤0.3 mm/m

3) Wedge Types

| Type | Features | Applications |

|---|---|---|

| Straight Wedge | Simple, economical | Standard generators |

| Dovetail Wedge | Excellent locking force | Hydro & turbo generators |

| Spring Wedge | Vibration-resistant | VFD motors, wind turbines |

| Split Wedge | Easy assembly | Large generators |

| Reinforced Wedge | Higher mechanical strength | Heavy-duty machines |

4) Surface Treatment Options

| Surface | Benefits |

|---|---|

| Smooth surface | Standard use |

| Roughened surface | Anti-slip, anti-loosening |

| Sanded/matte finish | Better friction, easier fit |

| Chamfering | Smooth insertion, avoids insulation damage |

| Moisture-proof coating | For damp environments |

| Insulation coating | Higher dielectric strength |

4. Advantages of G11 Compared to G10/FR4

| Property | G10 / FR4 | G11 | Result |

|---|---|---|---|

| Thermal class | 120–155°C | 180–200°C | G11 superior |

| High-temp strength | Medium | High | Not prone to softening |

| Electrical insulation | Good | Excellent | Safer for HV coils |

| Dimensional stability | Medium | High | Ideal for long-term load |

| Service life | Standard | Long | More reliable |

G11 is widely used in modern wind power, hydro, nuclear, and turbo-generator stators.

5. Typical Applications

Steam-turbine generators

Hydro generators

Wind turbine generators (DFIG, PMG)

Nuclear power generators

High-voltage synchronous motors

VFD motors and industrial generators

Contact manufacturer

Xujue Electrical is a professional manufacturer of electrical insulation materials, which can customize various motor insulation slot wedges according to customer provided drawings. If you need to learn more about G11 epoxy board product information and quotations, please contact us.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations