G11 Epoxy Glass Laminate in Test Fixtures | High Strength & Heat Resistance

What Is G11 Epoxy Glass Laminate? G11 epoxy glass laminate is a high-grade composite material made of alkali-free fi...

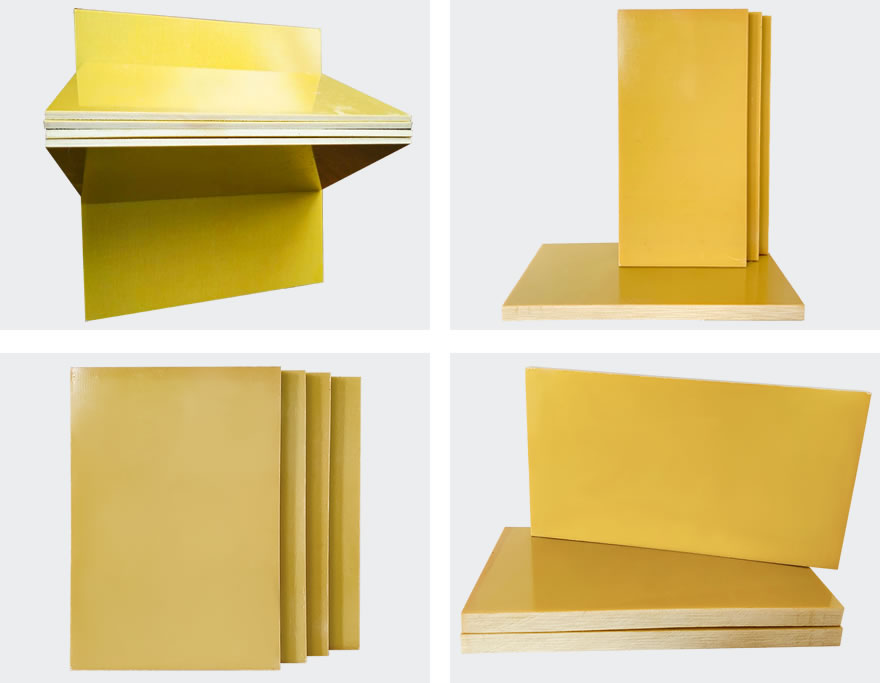

What Is G11 Epoxy Glass Laminate?

G11 epoxy glass laminate is a high-grade composite material made of alkali-free fiberglass cloth impregnated with epoxy resin and laminated under high temperature and pressure.

It meets NEMA G11, IEC 61212, and MIL-I-24768/3 standards.

Compared with FR4 or G10, G11 offers higher heat resistance (155–180°C), excellent mechanical strength, and outstanding electrical insulation — making it ideal for test fixtures and industrial testing equipment that operate under thermal and electrical stress.

Why Use G11 sheet in Test Fixtures?

Test fixtures (also called testing jigs or testing holders) are used to secure and connect components such as PCB boards, connectors, relays, or battery modules during electrical performance testing.

G11 is widely used as the insulating and supporting base due to its stability, strength, and electrical reliability.

| Application Area | Function | Reason for Using G11 |

|---|---|---|

| Insulating Support Plate | Separates high-voltage or signal circuits | Dielectric strength ≥ 19 kV/mm |

| Base Plate | Structural base for components and probes | High mechanical strength and dimensional stability |

| Probe Guide Plate | Aligns test probes precisely | Excellent wear resistance |

| Thermal Isolation Layer | Prevents heat conduction from DUT | Heat deflection >180°C |

| Mounting Brackets | Connects metal frames and circuits | High insulation and mechanical reliability |

G11 vs G10 vs FR4: Key Performance Comparison

| Property | FR4 / G10 | G11 | Advantage |

|---|---|---|---|

| Heat Resistance | 130°C | 155–180°C | Ideal for high-temp testing |

| Mechanical Strength | Good | Higher | No deformation under pressure |

| Water Absorption | 0.1–0.2% | Lower | Better dimensional stability |

| Electrical Strength | 17–19 kV/mm | 19–20 kV/mm | Safer for high-voltage tests |

| Dimensional Stability | Good | Excellent | Perfect for CNC precision machining |

Conclusion: G11 is the upgraded version of FR4 and G10, designed for continuous high-temperature, high-voltage testing in advanced industries.

Applications of G11 in Test Fixtures

1. PCB and ATE (Automatic Test Equipment) Fixtures

Used as the top and bottom support boards, probe guide plates, and fixture bases.

Provides high rigidity, insulation, and stability during repeated mechanical cycles.

2. Battery Pack Testing Equipment

Acts as an insulating support plate and thermal barrier for lithium battery cells during charge/discharge testing.

Prevents current leakage and deformation at high temperatures.

3. Automotive ECU and Relay Testing Fixtures

Used for structural frames and insulation layers in engine control module tests.

Resists heat, electrical arcing, and vibration during long testing cycles.

4. Power Module and High-Voltage Component Testing

Used as a high-voltage isolation plate or support block in IGBT and relay testing.

Withstands high dielectric stress and prevents breakdown.

5. Semiconductor Device Test Fixtures

Serves as the fixture skeleton or protective insert, ensuring accuracy and stability under high temperature and pressure.

Processing and Design Tips

CNC Machining:

G11 can be precisely cut, drilled, and milled.

Use carbide or diamond tools for the best surface quality.

Thread Inserts:

Use stainless-steel inserts or bushings to prevent stress cracking.

Hole Spacing:

Maintain >5 mm edge distance to avoid delamination.

Storage Conditions:

Keep in a dry environment (<60% humidity) and avoid prolonged UV exposure.

Why Choose XUJUE ELECTRICAL G11 for Test Fixtures

Xujue Electrical G11 epoxy fiberglass sheet are engineered for industrial-grade test environments.

Key advantages include:

Uniform epoxy resin impregnation and high laminate density

Superior delamination resistance and surface smoothness

Thickness range: 0.3 mm – 50 mm

Excellent machinability for CNC precision parts

Certified to UL 94 V-0 / RoHS / REACH standards

Widely used in ATE fixtures, battery pack testing, power module insulation parts

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations