G10 VS G11 Epoxy Fiberglass Tube

Difference Between G10 and G11 Epoxy Tubes G10 and G11 epoxy tubes are both made by rolling fiberglass cloth impregn...

Difference Between G10 and G11 Epoxy Tubes

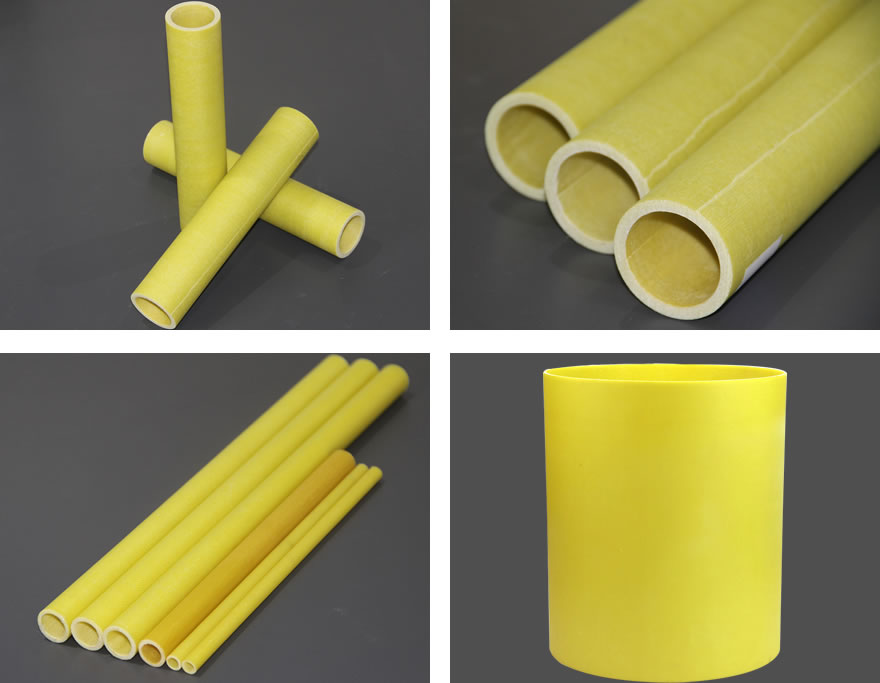

G10 and G11 epoxy tubes are both made by rolling fiberglass cloth impregnated with epoxy resin under heat and pressure. While they share a similar base structure, they differ significantly in performance characteristics and application suitability.

1. Heat Resistance Class

G10: Rated for Class B (130°C)

G11: Rated for Class H (180°C)

G11 maintains excellent electrical and mechanical properties under high-temperature conditions, making it more suitable for demanding thermal environments.

2. Resin System

G10: Uses standard epoxy resin

G11: Uses modified high-temperature epoxy resin

G11 offers superior thermal stability and better resistance to thermal aging.

3. Electrical Performance

G11 outperforms G10 in electrical insulation, especially under high temperatures or humid conditions.

4. Cost and Economic Consideration

G11 is more expensive than G10 in terms of material and processing costs.

G10 is cost-effective for environments below 130°C, while G11 is recommended for continuous high-temperature operation.

5. Typical Applications

| Application Area | G10 Epoxy Tube | G11 Epoxy Tube |

|---|---|---|

| Standard Motors/Transformers | Suitable | More suitable for high-temperature versions |

| Electronics Support | Commonly used | Better for internal support in hot devices |

| Aerospace & Military | Less common | Often used in high-temp, high-insulation environments |

Summary Comparison Table

| Comparison Aspect | G10 | G11 |

|---|---|---|

| Heat Resistance Class | Class B (130°C) | Class H (180°C) |

| Resin System | Standard epoxy resin | High-temperature modified epoxy resin |

| Electrical/Mechanical Performance | Good | Better, especially at high temperatures |

| Cost | Lower | Higher |

| Application Suitability | General/moderate environments | High-temp/demanding environments |

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations