G10 sheet applications and selection in switchgear

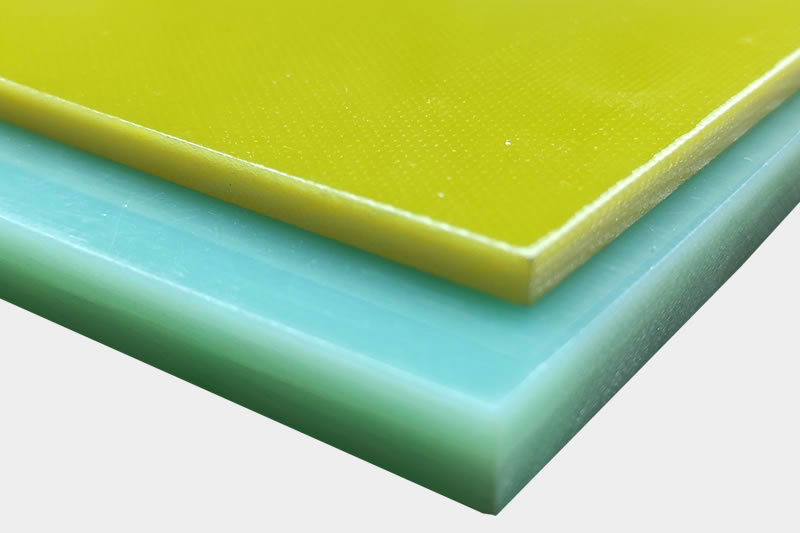

Applications of G10 Insulation sheet in Switchgear Insulating Support Components Application: Used to suppor...

Applications of G10 Insulation sheet in Switchgear

- Insulating Support Components

Application: Used to support and fix busbars inside the switchgear, ensuring safe clearance between phases and structural stability.

Features: Excellent dimensional stability and dielectric strength; capable of withstanding high voltage and mechanical loads over long periods.

- Barrier Boards / Interphase Insulation

Application: Provides electrical isolation between phases or between phase and ground, effectively preventing arc flash or flashover incidents.

Features: High dielectric strength and heat resistance; can withstand temporary overvoltage conditions.

- Bent or Custom-Shaped Parts

Application: Formed through CNC machining or thermoforming; used as brackets, connectors, or structural parts in complex assemblies.

Features: Highly machinable and customizable to meet the needs of non-standard switchgear designs.

- Mounting Base Plates / Insulating Pads

Application: Serve as mounting bases for electrical components or insulating spacers to eliminate conductive contact between metal parts.

Features: Smooth surface, flatness, and easy installation and maintenance.

Selection Guidelines for G10 in Switchgear

| Selection Criteria | Recommendations |

| Thickness | Common thicknesses include 3mm, 5mm, 8mm, and 10mm, selected based on voltage rating and structural load; 8–10mm is typical for main busbar supports. |

| Thermal Class | G10 typically meets Class B (130°C) requirements, suitable for medium and high-voltage switchgear. For higher thermal demands, G11 (Class H, 180°C) is recommended. |

| Mechanical Strength | Use high-strength G10 boards with flexural strength over 350 MPa to ensure long-term mechanical performance. |

| Machining Precision | For complex parts, choose boards with smooth surfaces and tight thickness tolerances to maintain dimensional accuracy after machining. |

| Flame Retardancy | If flame resistance is required, consider using FR4 (flame-retardant grade of G10) as an alternative. |

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations