G10 Insulation Gaskets Introduction and Applications

Introduction to G10 Insulation Gaskets G10 insulation gaskets are high-performance insulating components made by mac...

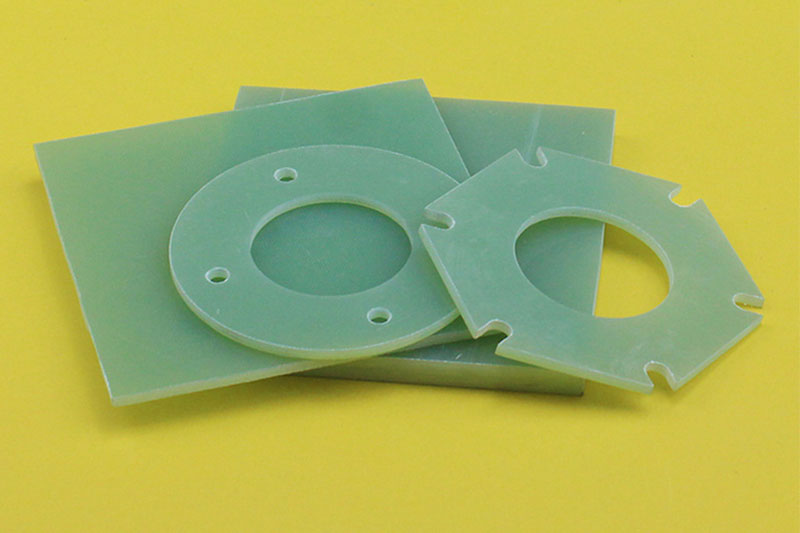

Introduction to G10 Insulation Gaskets

G10 insulation gaskets are high-performance insulating components made by machining or stamping G10 epoxy laminate sheets, which are composed of fiberglass cloth and epoxy resin. They offer excellent electrical insulation, mechanical strength, and dimensional stability, making them ideal for high-voltage, high-load, and high-reliability applications.

Key Performance Characteristics

| Property | Description |

|---|---|

| High Electrical Insulation | Dielectric breakdown strength ≥ 20kV/mm, suitable for high-voltage environments |

| Excellent Heat Resistance | Continuous operating temperature: 110°C; short-term resistance up to 130–140°C |

| High Mechanical Strength | Flexural strength ≥ 300 MPa, strong resistance to compression and impact |

| Dimensional Stability | Low thermal expansion, maintains shape in precision structures |

| Chemical Resistance | Resistant to oils and mild acids/alkalis; suitable for industrial conditions |

| Flame Resistance | G10 is non-flame retardant (use FR4 if flame resistance is required) |

3. Common Applications

Insulation in Transformers and Reactors

Used between high and low voltage windings

Acts as insulating structural supports in mounting areas

Power System Accessories

Insulation spacers in high-voltage switchgear, cable terminations, and grounding systems

Electrical isolation for busbar and copper connections

Electronics and Devices

Base insulation layer for PCBs or power modules

Support gaskets within control panels

Industrial Machinery and Automation

Dual-purpose insulating and structural parts in assembly systems

Machining and Specifications

| Item | Details |

|---|---|

| Thickness Range | Typically 0.3mm to 20mm, custom sizes available |

| Shapes | Round, square, custom cut-outs, holes, slots, chamfers, etc. |

| Tolerance Accuracy | ±0.05mm (CNC machining), ideal for precision assemblies |

| Surface Treatments | Optional coating, sanding, moisture-proofing, or lamination |

Common FAQs

Q1: Can G10 gaskets replace FR4?

A: Yes, in non-flame-retardant applications. For UL-certified or flame-resistant uses, FR4 is recommended.

Q2: Is G10 suitable for high-humidity environments?

A: G10 has a low water absorption rate and performs well in humid environments. However, for prolonged exposure to moisture or hot and humid conditions, edge sealing or protective treatments are recommended.

Q3: Are custom drawings supported for gasket production?

A: Yes. G10 sheets can be precisely machined according to custom CAD drawings using CNC, suitable for batch production in industrial settings.

Purchasing Recommendations

Recommended Industries: Power equipment manufacturing, industrial automation, electrical control panels, railway systems

Choose Certified Materials: UL-listed, RoHS, REACH compliant

Confirm with Supplier:

Material grade, dielectric strength, density, machining tolerance, and color

Whether it’s machined from original sheets and whether it includes a fiber-locking surface treatment (to reduce fiber shedding over time)

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations