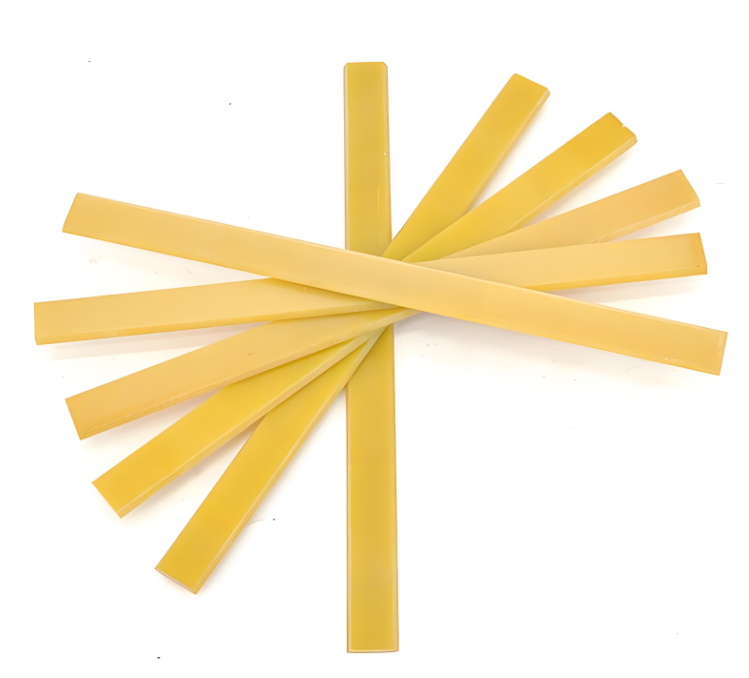

G10 epoxy sheet in Slot Wedge Applications

I. Introduction to G10 Epoxy sheet G10 is an epoxy resin–based laminate reinforced with glass fiber cloth and manufa...

I. Introduction to G10 Epoxy sheet

G10 is an epoxy resin–based laminate reinforced with glass fiber cloth and manufactured under high temperature and high pressure.

Key properties:

High mechanical strength (retains stability even at elevated temperatures)

Excellent electrical insulation

Thermal class B (around 130℃)

Good dimensional stability, wear resistance, and moisture resistance

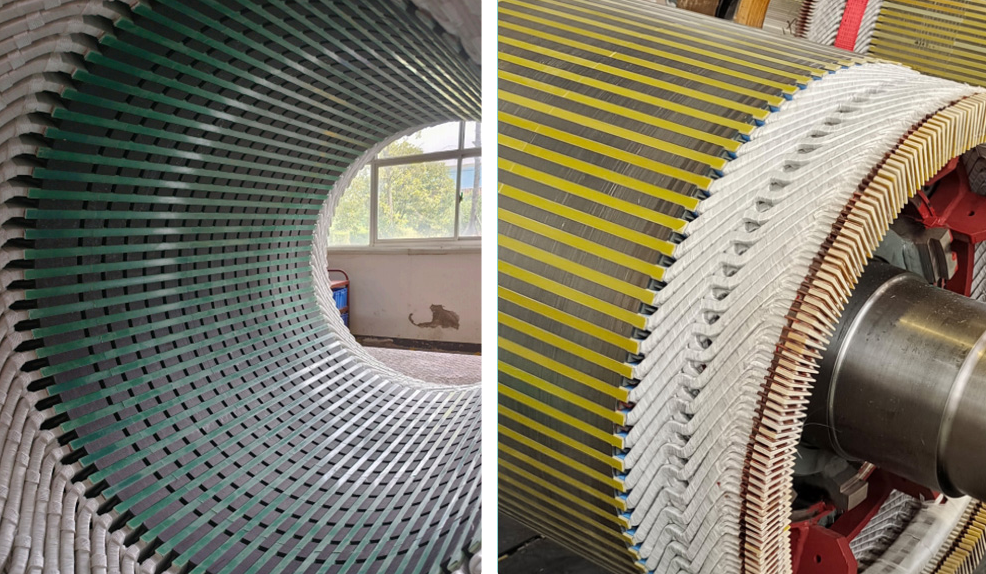

II. Function of Generator Slot Wedges

In a generator stator core, after the coils are inserted into the slots, slot wedges are used for fixing. Their functions include:

Mechanical fixation – Preventing coils from loosening or shifting due to electromagnetic forces or vibration.

Insulation protection – Avoiding direct contact between the coil and the stator core slots.

Electromagnetic optimization – The right wedge material helps reduce air-gap magnetic field distortion, lowering losses and noise.

III. Advantages of G10 sheet in Slot Wedge Applications

High mechanical strength – Withstands electromagnetic forces and slot pressure during operation.

Good thermal resistance – Suitable for Class B insulation systems (≤130℃), with stable long-term performance.

Excellent insulation properties – Ensures the reliability of the insulation system and prevents partial discharge.

Good machinability and dimensional stability – Can be precisely processed into wedge shapes for tight slot fitting.

Cost-effectiveness – More economical compared with G11 or aramid composite wedges, while still meeting performance requirements.

IV. Selection Guidelines

When selecting G10 slot wedges, consider the following aspects:

Insulation Class of the Generator

For Class B (130℃) and below → G10 slot wedges are sufficient.

For Class F (155℃) and above → G11 is recommended for better thermal resistance.

Generator Size and Operating Conditions

Small to medium generators → G10 meets both strength and insulation requirements.

Large generators or high-load operation → G11 or aramid composites are preferred for better fatigue and thermal performance.

Dimensional Requirements

The thickness of the wedge must match the slot size to ensure proper fit, avoiding looseness or excessive tightness.

Can be processed into various shapes (straight wedge, ripple wedge, etc.).

Operating Environment

For humid or chemically corrosive environments → surface treatment for moisture resistance is recommended, or epoxy glass fabric tubes can be used as wedges.

V. Material Selection Comparison

| Material Type | Insulation Class | Features | Application |

|---|---|---|---|

| G10 | Class B (130℃) | High mechanical strength, cost-effective | Standard generator slot wedges |

| G11 | Class F (155℃) | Higher thermal resistance, stable strength | High-power generators |

| Aramid composite wedges | Class H (180℃) | Excellent high-temperature and fatigue resistance | High-end generators, nuclear, aerospace |

| Epoxy wedges (non-cloth base) | Class B/F | Easy to process, low cost | Small and medium generators, cost-sensitive projects |

Summary:

G10 epoxy laminate slot wedges are widely used in generators due to their reliable mechanical and insulation performance, making them suitable for Class B and below, especially small and medium generators. For higher thermal resistance and service life requirements, G11 or aramid composite wedges are recommended.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations