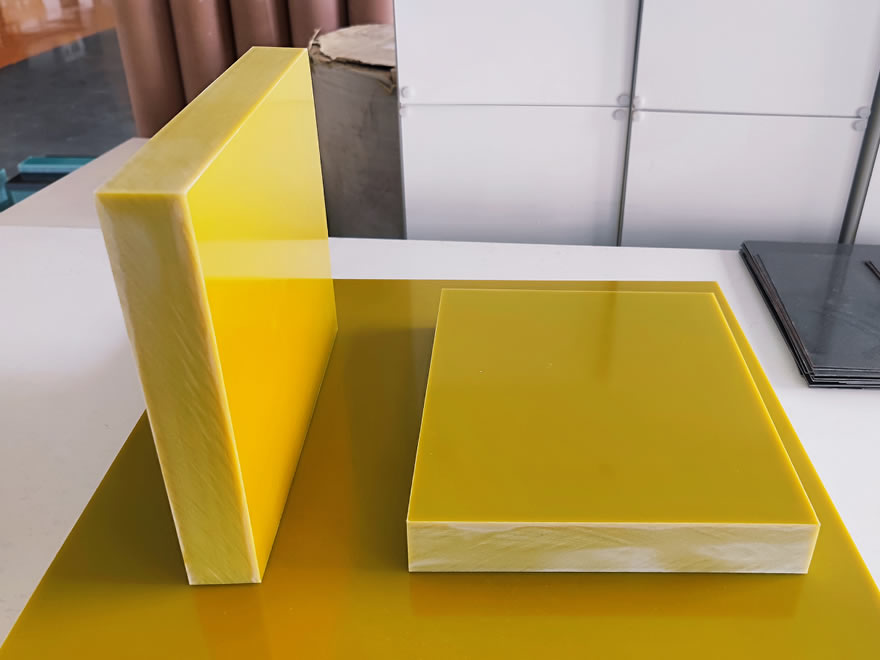

G10 Epoxy sheet for Fixtures: Applications and Advantages

G10 epoxy sheet is a high-end industrial laminate favored in fixture manufacturing. It's also known as "fiberglass s...

G10 epoxy sheet is a high-end industrial laminate favored in fixture manufacturing. It’s also known as “fiberglass sheet” or “epoxy glass cloth laminate” for its exceptional overall performance.

I. Core Properties of G10 Epoxy Sheet (Why is it Suitable for Fixtures?)

G10’s widespread use in fixtures is primarily due to its following key properties:

Extreme Strength and Rigidity

G10 is made by laminating fiberglass cloth and epoxy resin under high temperature and pressure, resulting in a very high strength-to-weight ratio. This means it can withstand significant clamping forces without bending or breaking, ensuring machining accuracy.

Excellent Insulation

G10 is an excellent electrical insulator. When machining or testing electronic components and circuit boards, using G10 fixtures completely eliminates the risk of short circuits, protecting products and equipment.

Zero Hygroscopicity

G10 does not absorb moisture. In humid environments or when coolant is required, it will not rust like metal, nor will it swell and deform due to water absorption like some wood or plastics, maintaining long-term dimensional stability.

Chemical Resistance

Its excellent resistance to most common solvents, oils, and coolants makes it highly durable in the complex chemical environments of machine shops.

Good Machinability

Despite its exceptional hardness, G10 can be easily machined into a variety of complex shapes using conventional machining methods (such as CNC milling, drilling, turning, and wire cutting). This is crucial for creating customized, high-precision fixtures.

Wear Resistance

The hard, smooth surface offers excellent wear resistance, allowing it to withstand repeated clamping and removal of workpieces, ensuring a long service life.

Non-magnetic

This property makes it an irreplaceable material in applications requiring protection from magnetic field interference, such as magnetic chucks and precision electromagnetic measurement environments.

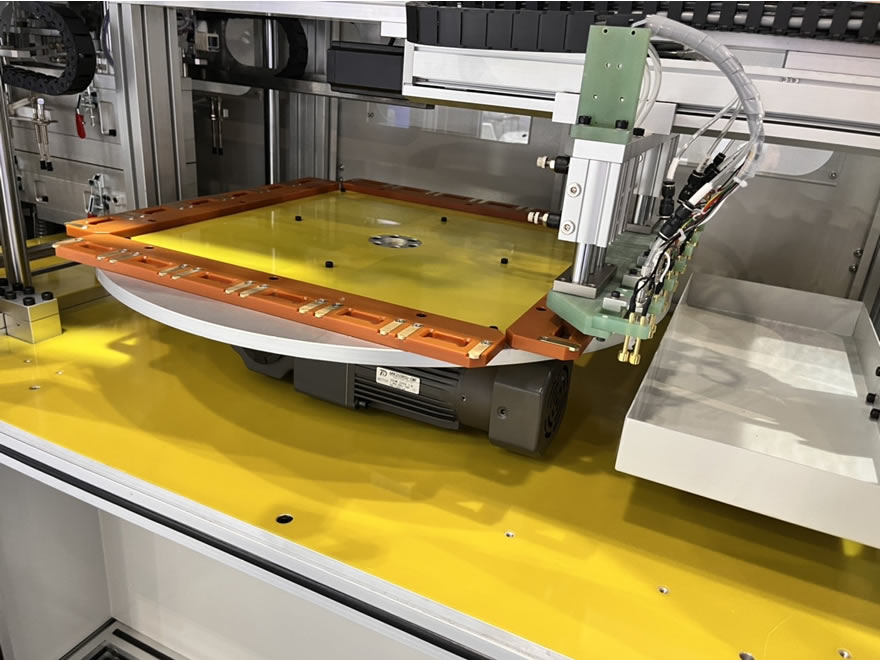

II. Specific Applications of G10 in Fixtures

In fixture design, G10 is commonly used as the following components:

Locate and Support Blocks

It is used to support and determine the position of the workpiece. Due to its high strength, it can be made relatively thin and lightweight, providing more room for tool manipulation. Its insulating properties prevent scratching of conductive workpiece surfaces.

Pressure Plates and Jaws

Clamping components that directly contact the workpiece surface. G10 is hard enough to provide a secure clamp, yet softer than metal, so it won’t scratch or damage finely machined work surfaces (such as aluminum alloys, copper, and polished parts).

Insulating Spacers and Spacers

In welding fixtures and circuit board test fixtures, G10 is a standard base plate or insulating material used to secure electronic components and prevent unintended electrical continuity between circuits.

V-Blocks

Used for clamping cylindrical workpieces. V-Blocks made of G10 are lightweight, wear-resistant, and gentle on the workpiece.

Specialized Fixture Bodies

For specialized applications requiring lightweight and high insulation requirements, the entire fixture body may be machined from G10 sheet metal.

III. Practical Application Examples

CNC machining center fixtures: When machining aluminum or copper parts, using pressure plates and locating blocks made of G10 provides a secure clamp while preventing galvanic corrosion and surface markings.

PCB (Printed Circuit Board) Test Fixtures: G10 is the primary material used in flying probe testers, ICT test fixture substrates, and probe support plates.

Soldering Fixtures: In the automotive and consumer electronics industries, G10 fixtures are used to secure circuit boards and wiring harnesses for soldering, ensuring precise positioning and absolute insulation.

Precision Measuring Fixtures: On coordinate measuring machines (CMMs) and other inspection equipment, using G10 fixtures can prevent interference or damage to the workpiece being measured.

IV. Precautions for Using G10

Processing Dust: This is the most important safety precaution! The fiberglass dust generated during G10 machining is irritating to the skin, eyes, and respiratory system. Appropriate dust removal equipment (such as a vacuum cleaner) is essential, and operators should wear dust masks and goggles.

Interlaminar Strength: Although G10 boards have high in-plane strength, their interlaminar peel strength is relatively low. When designing fixtures, avoid excessive impact or splitting forces in the thickness direction.

Temperature Limitations: G10’s long-term operating temperature is typically around 130°C (the glass transition temperature of epoxy resin). Its strength and insulation properties degrade at higher temperatures (such as high-temperature baking or hot pressing).

Cost: G10 is more expensive than steel, aluminum, or some engineering plastics, but its performance advantages (such as workpiece protection, insulation, and maintenance-free) often justify its value.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations