G10 Epoxy sheet– Common Thicknesses & Selection Guide

Introduction to G10 Epoxy sheet G10 epoxy sheet is a high-strength fiberglass-reinforced epoxy laminate, known for ...

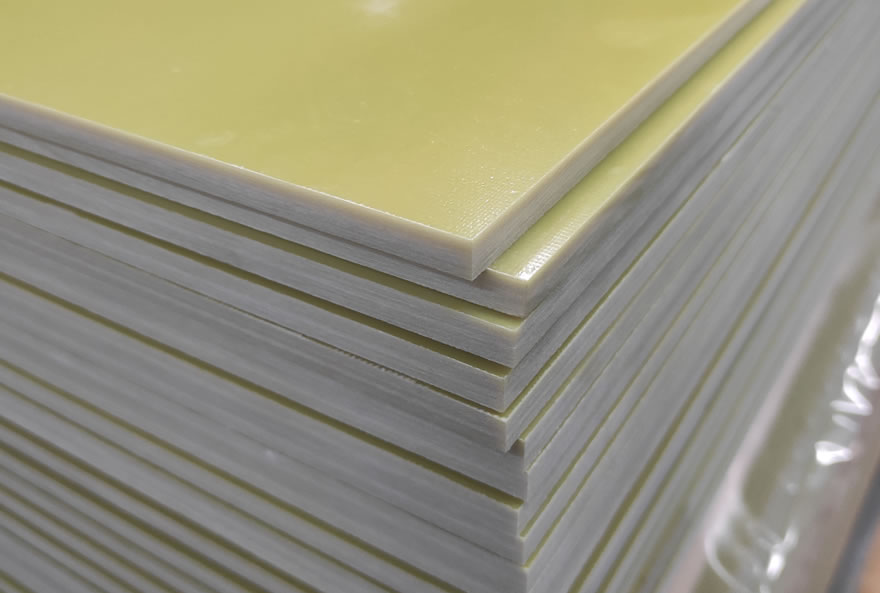

Introduction to G10 Epoxy sheet

G10 epoxy sheet is a high-strength fiberglass-reinforced epoxy laminate, known for its excellent mechanical strength, electrical insulation properties, low moisture absorption, and strong oil resistance. It is widely used in electrical, mechanical, and industrial applications.what is the typical thickness of G10 epoxy board? Today, Xujue Electrical will give you a detailed guide on common G10 epoxy board thicknesses and how to select them.

1.Recommended Thickness by Application (Quick Selection Table)

| Application / Part | Recommended Thickness (mm) | Reason |

|---|---|---|

| Thin insulation sheets, light-duty separators | 0.5–1.2 mm | Flexible, lightweight, non-load-bearing insulation |

| Internal isolation plates | 1.6–2.0 mm | Basic rigidity + electrical insulation |

| Equipment structural insulation parts | 3–6 mm | Higher mechanical strength and stability |

| Transformer terminal boards / motor end plates | 5–10 mm | Withstand bolt torque, high dielectric strength |

| HV insulating barriers, phase separators | 8–20 mm | Higher creepage distances and rigidity |

| Load-bearing insulating blocks | 10–30 mm | Strong bending and compressive strength |

| Large structural insulation components | 20–50 mm | For large machines and oil-immersed environments |

2. When to Choose G10 Instead of FR4

Better mechanical strength

More stable dielectric properties

Superior oil resistance → suitable for transformers

Higher thermal rating (commonly Class F / 155°C)

However, G10 is not flame-retardant (unlike FR4).

If UL94 V-0 is required, choose FR4 or G11 V-0 grade.

3. Selection Guidelines (Engineering Steps)

Operating environment

Oil-immersed, high-humidity, high-temperature → choose G10

Flame-retardant requirement → avoid G10

Mechanical load

Load-bearing components → 5 mm, 10 mm, 20+ mm depending on force

Electrical insulation requirements

Higher voltage → use thicker plates (8–20 mm)

Processing method

CNC machining → thick plates OK

Punching → ≤2 mm only

Tolerance & surface finish

Common thickness tolerance: ±0.1 mm

High precision: ±0.05 mm

4. Fast Selection for Transformer Applications

| Transformer Component | Recommended Thickness | Reason |

|---|---|---|

| Terminal boards | 5–10 mm | Mechanical load + insulation |

| Phase separators | 6–12 mm | Mechanical rigidity + creepage distance |

| High-voltage insulation barriers | 10–20 mm | High dielectric & mechanical strength |

| Structural support blocks | 10–30 mm | Strong load-bearing performance |

| Oil-immersed insulation parts | 8–20 mm (G10 recommended) | Excellent oil resistance |

5.Contact the manufacturer

If you are looking for G10 epoxy fiberglass sheets, please contact Xujue Electrical and provide the product specifications, thickness and purpose you need, you can get detailed product information and quotation, and also send samples free of charge

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308