FR4 vs G10 vs G11 for Generator Slot Wedges | Selection Guide

Generator slot wedges are critical insulation and structural components installed at the slot openings of stator wind...

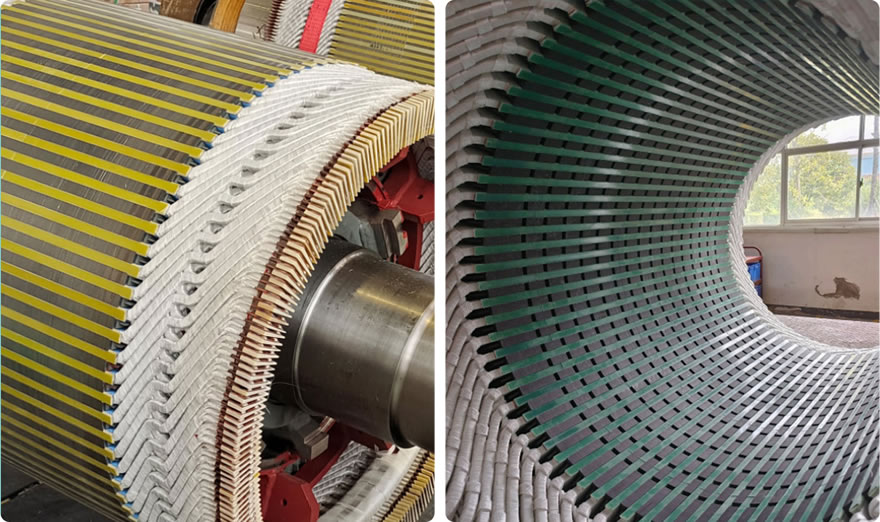

Generator slot wedges are critical insulation and structural components installed at the slot openings of stator windings. Their primary functions are to secure the windings, prevent vibration and displacement, and withstand electromagnetic forces and thermal stress. Proper selection of slot wedge materials directly affects generator reliability, insulation lifetime, and maintenance intervals.

Among various insulation materials, FR4, G10, and G11 epoxy laminate sheets are the most mature and widely used solutions for generator slot wedge applications. This guide provides a systematic overview of material properties, application scenarios, and selection principles.

I. Key Requirements for Generator Slot Wedge Materials

Slot wedges operate under combined conditions of high temperature, vibration, electromagnetic force, and electrical stress, requiring materials with the following characteristics:

High mechanical strength to prevent loosening or breakage

Stable dielectric strength to avoid partial discharge

Excellent thermal resistance and aging performance

Dimensional stability for precise machining and installation

Compatibility with VPI (Vacuum Pressure Impregnation) resins

II. Performance Comparison of FR4 / G10 / G11

| Item | FR4 | G10 | G11 |

|---|---|---|---|

| Base Material | Glass fiber cloth + epoxy resin | Glass fiber cloth + epoxy resin | Glass fiber cloth + high heat-resistant epoxy |

| Flame Retardancy | UL94 V-0 | Not mandatory | Not mandatory |

| Thermal Class | Class B(130°C) | Class B(130°C) | Class F/H (155°C/180°C) |

| Mechanical Strength | High | High | Higher |

| Dielectric Properties | Stable | Stable | Stable |

| Cost | Medium | Medium | Higher |

III. Application of FR4 in Generator Slot Wedges

Suitable Applications

Small to medium-sized generators

Insulation systems up to Class F

Projects with mandatory flame-retardant requirements

Advantages

Excellent flame retardancy and safety performance

Good machinability and dimensional stability

Cost-effective and widely available

Recommendation

FR4 is suitable for industrial generators, standby generators, and auxiliary power systems operating under stable conditions.

IV. Application of G10 in Generator Slot Wedges

Suitable Applications

Medium to large generators

Designs emphasizing mechanical strength and rigidity

Applications where flame retardancy is not a mandatory requirement

Advantages

High flexural strength and excellent vibration resistance

Reliable electrical insulation performance

Competitive cost-to-performance ratio

Recommendation

G10 is commonly used in industrial power generators and export-oriented generator projects, especially where structural strength is prioritized.

V. Application of G11 in Generator Slot Wedges (Premium Option)

Suitable Applications

High-voltage and large-capacity generators

Class H or higher insulation systems

High-temperature, heavy-load, and continuous-duty operations

Advantages

Superior thermal resistance (up to 180°C)

Slower thermal aging and longer service life

Maintains structural integrity under strong electromagnetic forces

Recommendation

G11 is strongly recommended for 6 kV / 10 kV and above generators, continuous full-load operation, and critical power plant applications.

VI. Quick Selection Guide for Generator Slot Wedge Materials

Based on Insulation Class

Class F → FR4 / G10

Class H → G11

Based on Operating Conditions

Normal load → FR4 / G10

High temperature & heavy load → G11

Based on Standards & Market Requirements

Strict safety or European standards → FR4

Mechanical strength prioritized → G10

VII. Engineering Selection Notes

Slot wedge thickness must match slot dimensions precisely

Ensure material compatibility with VPI resins

Avoid using lower thermal-class materials in high-temperature systems

High-voltage generators should undergo dielectric and partial discharge testing

Get samples and manufacturer quotations

FR4, G10, and G11 epoxy laminate sheets are proven and reliable materials for generator slot wedge applications. Proper selection based on insulation class and operating conditions significantly enhances generator stability and extends insulation system service life.

XUJUE ELECTRICAL is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 65 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first.

If you are looking for FR4/G10/G11 epoxy sheet or Slot Wedge Materials, please contact us, we will provide you with product catalog and quotation, and can also mail you free samples for your testing.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted