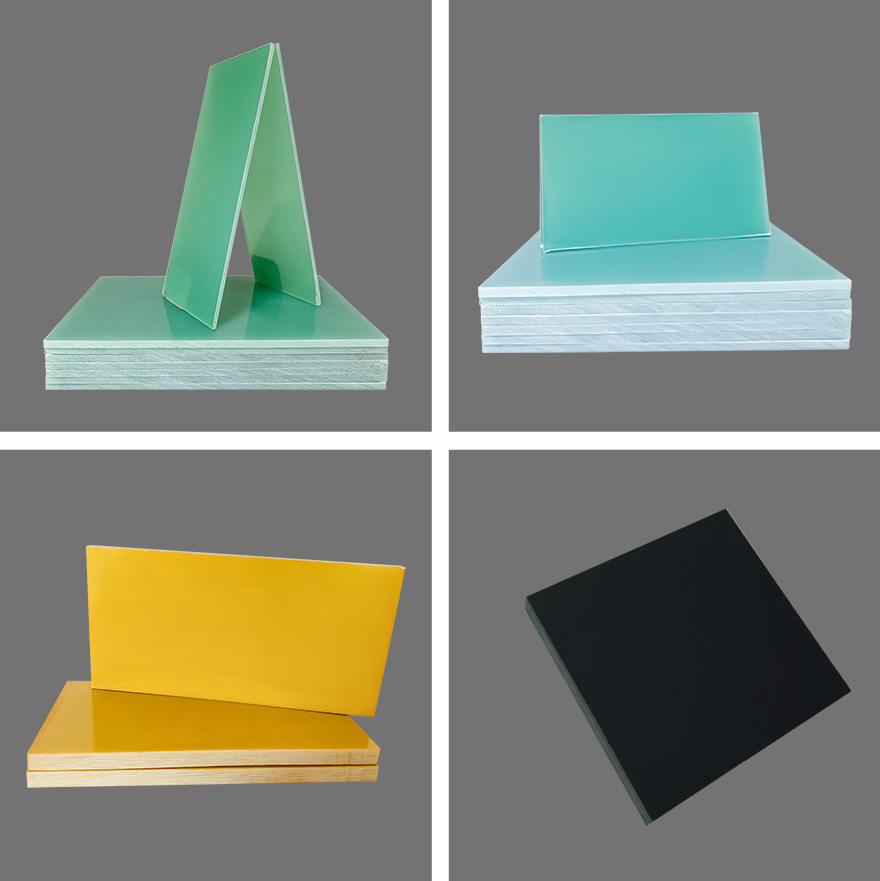

FR4 sheet in New Energy Battery Insulation Boards

FR4 sheet is a composite insulation material made of glass fiber cloth impregnated with epoxy resin. It features high...

FR4 sheet is a composite insulation material made of glass fiber cloth impregnated with epoxy resin. It features high mechanical strength, excellent electrical insulation, high temperature resistance (generally 130–155°C), moisture resistance, and flame retardancy (UL94 V-0), making it ideal for structural insulation in power battery systems.

FR4 epoxy sheet(White)

1. Application Location and Function

Cell Spacer

Places between individual battery cells to prevent vibration, displacement, or extrusion from causing short circuits in the metal casing. It also provides cushioning and deformation resistance.

Module Top/Bottom Insulation Board

Isolates the battery cells from the module casing, base plate, or top cover. It improves overall module rigidity and prevents conductive components from contacting the casing.

End Plate Insulation Layer

Located between the module end plate and the high-voltage busbar/conductor, it prevents breakdown and leakage.

Insulation Layer under the BMS Protection Board

Prevents short circuits caused by contact between solder joints on the back of the PCB and metal components.

Thermal Management Isolation

Combined with thermally conductive gaskets, aluminum substrates, etc., it acts as an insulating medium to separate high-voltage components from metal cooling components.

Fr4 Epoxy glass fiber sheet (green/yellow/black)

Key Points for Selecting FR4 Battery Insulator Boards

1. Thickness Selection

| Application Position | Common Thickness Range | Selection Notes |

|---|---|---|

| Cell Spacers | 0.2–0.8 mm | Balances insulation and weight; greater thickness improves mechanical support but increases weight |

| Module Top/Bottom Boards | 1.0–2.0 mm | Enhances module rigidity and withstands assembly pressure |

| End Plate Insulation | 0.8–1.5 mm | Dielectric margin should be at least twice the operating voltage |

| BMS Insulation | 0.3–0.8 mm | Thin and lightweight for easy assembly while meeting dielectric requirements |

2. Voltage Rating

Common operating voltage for power battery systems: 300–800V

Voltage rating for insulation boards: ≥2kV (AC 1min). A safety factor of 2–3 times is recommended.

Optional: Standard FR4 (dielectric strength 14–18 kV/mm) or high-voltage modified FR4.

3. Flame Retardancy and Environmental Requirements

Flame Retardancy Rating: UL94 V-0

Compliant with ROHS/REACH halogen-free environmental standards

4. Heat Resistance

Conventional FR4: Tg 130–140°C

High Tg FR4: Tg 150–170°C, suitable for high-temperature environments (such as where the battery compartment is adjacent to the motor controller).

5. Processing and Structural Design

Molding Method: CNC Milling, laser cutting, and stamping

Design: Capable of designing through-holes, slots, chamfers, and positioning bosses

Laminar layer: Can be laminated with PI (polyimide) and PET films to enhance heat and wear resistance

Selection Examples

High-power passenger vehicle battery pack: Choose 1.5 mm high-Tg FR4 for the module base plate and 0.5 mm standard FR4 for the inter-cell separators.

Commercial vehicle battery pack: Choose 1.0 mm high-voltage FR4 for the module end plate insulation layer and 2.0 mm FR4 for the top protection.

Lightweight energy storage system: Choose 0.4 mm FR4 for the BMS base plate and 1.0 mm FR4 for the module upper and lower plates.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations