FR4 Material Applications in the Electrical Industry

FR4 Material Applications in the Electrical Industry FR4 material is primarily used in strong-current fields (e.g., ...

FR4 Material Applications in the Electrical Industry

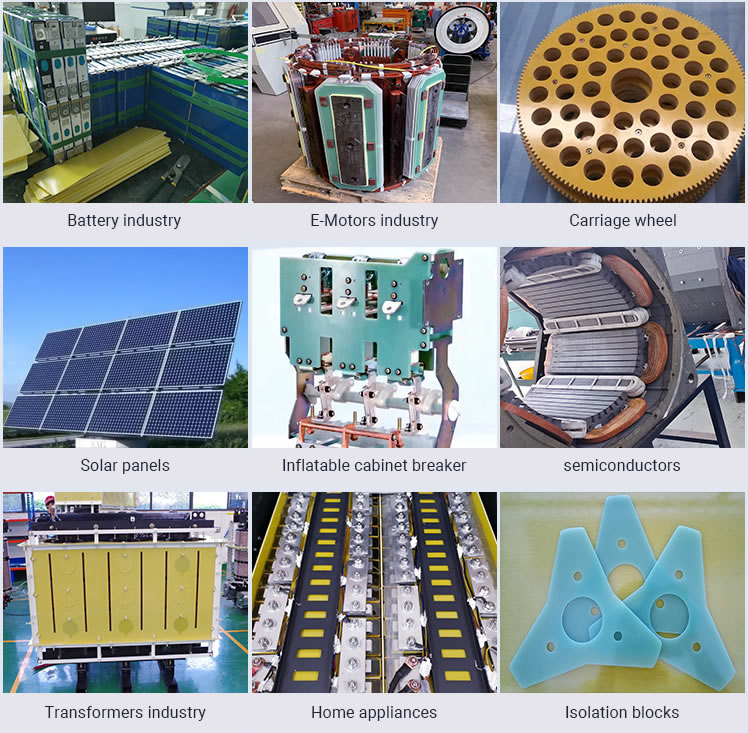

FR4 material is primarily used in strong-current fields (e.g., power transmission, distribution equipment, motors, electrical appliances) for components requiring high-performance insulation, mechanical support, and heat/flame resistance. Core applications and rationale:

Core Application Areas

Insulation Structural Components

Slot wedges/Insulation blocks: Fix coils in motor/transformer stator slots to prevent vibration displacement (FR4’s mechanical strength/heat resistance exceeds traditional epoxy boards).

Circuit breaker barriers: Phase-to-phase insulation barriers in LV/MV switchgear to block arcs (UL94 V-0 flammability rating is critical).

Terminal blocks: Support electrical terminals and isolate conductive parts (relying on dielectric strength >20 kV/mm).

Power Distribution Equipment Substrates

Metering/control box PCBs: Control boards in smart meters and distribution automation devices (FR4 is the preferred PCB substrate).

Relay/contactor bases: Insulating frames for contact structures (arc resistance/carbonization resistance).

Power Electronics Modules

IGBT module substrates: Insulating substrates for power modules in LV/MV drives/UPS (require high-thermal-conductivity FR4 variants).

Power module PCBs: Power conversion boards in EV chargers/inverters (high-temperature resistance/tracking resistance).

Key Advantages of FR4

| Property | Value in Electrical Industry | Application Example |

| High insulation strength | Withstands kilovolt-level voltages | Circuit breaker phase barriers |

| Flame resistance (UL94 V-0) | Prevents flame propagation during faults | Motor slot wedges |

| Mechanical rigidity | Supports heavy conductors/vibration | Transformer winding supports |

| Heat resistance (Tg≥130°C) | Tolerates motor heating/short-circuit temps | E-drive control boards |

| Chemical resistance | Resists oils/coolants | Industrial motor insulation |

Specific Applications in Typical Equipment

Dry-type transformers: Interlayer insulation spacers/end rings (FR4 replaces epoxy laminates for extended lifespan).

HV switchgear: Busbar support insulators/breaker chassis (superior mechanical strength vs. SMC).

Wind turbines: Converter control boards/sensor interfaces (resists humidity/salt spray).

Power tools: Motor commutator PCBs/power switch boards (impact resistance + flame retardancy).

Key Requirements

Electrical industry demands enhanced FR4 grades:

High CTI (Comparative Tracking Index): >600V (essential for humid environments).

High-Tg variants (e.g., Tg170°C): For high-temperature motors/dense switchgear.

Halogen-free flame retardancy: Meets eco/low-toxicity standards (e.g., IEC 61249-2-21).

Summary: FR4 serves as the “structural backbone of insulation systems” in electrical applications – resisting electrical stress (HV insulation), thermal stress (temperature rise), mechanical stress (vibration/impact), and preventing fire propagation. It underpins the safe operation of high-power equipment.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations