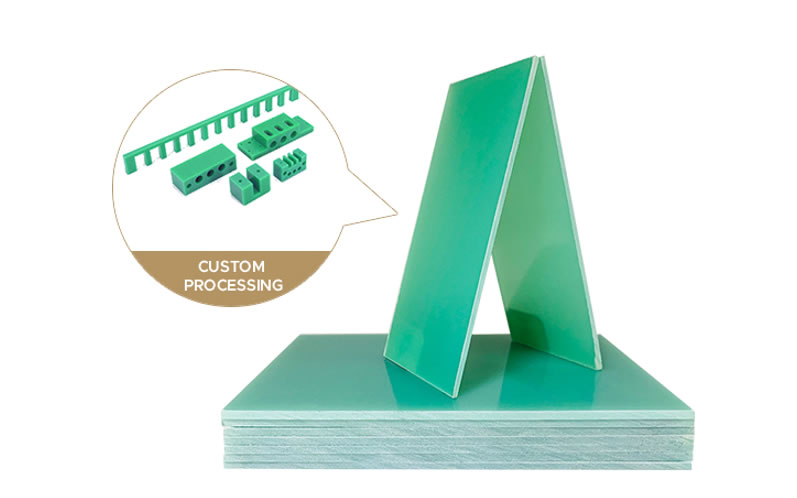

FR4 Epoxy Sheet Heat Resistance Rating & Selection Guide

1.Heat Resistance Rating of FR4 (Accurate Version) FR4 epoxy sheet is a composite material made from epoxy resin and...

1.Heat Resistance Rating of FR4 (Accurate Version)

FR4 epoxy sheet is a composite material made from epoxy resin and woven fiberglass cloth. Its thermal capability mainly depends on the resin system, Tg, and curing process.

Continuous Working Temperature of FR4: 130–150°C

| Type of FR4 | Continuous Operating Temperature | Thermal Class | Notes |

|---|---|---|---|

| Standard FR4 | 110–130°C | Class B (130°C) | Used in general-purpose PCBs and electrical insulation parts |

| Enhanced / Modified FR4 | 130–150°C | Close to Class F (155°C) | Used for electrical insulation structural parts |

| High Tg FR4 (Tg150 / Tg170) | ≈150°C (not exceeding 160°C) | Not an H-class material | High Tg ≠ high continuous operating temperature |

Important Clarification

High Tg FR4 (e.g., Tg170) does NOT mean it can operate continuously at 170°C.

Tg (glass transition temperature) indicates the temperature at which the resin starts to soften

It is not the allowable long-term operating temperature

Even high-Tg FR4 typically supports only ≤150°C continuous usage

2. Thermal Resistance Comparison With Similar Materials

To help engineers make decisions quickly, below is a comparison between FR4 and other common insulation laminates:

| Material | Continuous Temperature | Thermal Class | Characteristics |

|---|---|---|---|

| FR4 | 130–150°C | B ~ F | Low cost, good machinability, widely used |

| G10 | 130°C | B | Good mechanical strength, moderate heat resistance |

| EPGC203 | 155°C | F | Widely used in electrical and power equipment |

| G11 | 180°C | H | High temperature & high reliability applications |

| EPGC204 | 180–200°C | H | Premium high-temperature laminate |

3. How to Select FR4 for Engineering Applications

Below is a practical decision-making process used by engineers.

1) Selection by Temperature (Most Critical)

| Application Temperature | FR4 Applicable? | Recommended Material |

|---|---|---|

| ≤120°C | ✔ Fully suitable | Standard FR4 |

| 120–140°C | ✔ Use enhanced FR4 | Modified FR4 |

| 140–155°C | ⚠ Borderline, near performance limit | EPGC203 recommended |

| 155–180°C | ✘ Not suitable | G11 |

| ≥180°C | ✘ Forbidden | H-class or PI-based insulation |

2) Selection by Voltage Level

| Voltage Level | FR4 Suitability | Notes |

|---|---|---|

| Low voltage ≤1kV | ✔ Very suitable | PCB, low-voltage insulation |

| Medium voltage 3–12kV | ✔ With high-quality FR4 | Use ≥3–5mm thickness |

| 24–40kV | ⚠ Not recommended | Use EPGC203 or G11 |

| ≥66kV | ✘ Not suitable | Requires high-voltage pressboard/laminate |

3) Selection by Mechanical Load

FR4 has moderate mechanical strength. For heavy-load applications, it is not recommended.

| Load Level | FR4 Suitable? |

|---|---|

| Light load (electronic parts, PCB) | ✔ |

| Medium load (general support pieces) | ✔ with thicker FR4 |

| Heavy load (transformer clamping plates, structural supports) | ✘ Use EPGC203 / G11 |

4) Selection by Application Scenario

| Application | Recommended Material | Reason |

|---|---|---|

| PCB, control boards | FR4 | Standard application |

| Low-voltage insulation | FR4 | Adequate thermal capability |

| Switchgear partition (medium voltage) | Thick FR4 / EPGC203 | Depends on voltage level |

| Transformer clamping parts | ❌ Not FR4 | Insufficient strength & heat resistance |

| Inverters, power modules | High Tg FR4 | Suitable if temperature rise is controlled |

| Energy storage systems, PV | EPGC203 | Higher safety requirement |

| High-temperature motors, transformers | G11 / EPGC204 | H-class needed |

4. One Sentence Summary for Engineers

FR4’s reliable heat resistance: 130–150°C.

Do NOT use FR4 for >150°C, high-voltage, or heavy-load environments.

For improved reliability → EPGC203 (155°C)

For high-temperature 160–180°C → G11 (180°C)

Xujue Eeletrical is a professional manufacturer of high-quality electrical insulation materials with more than 65 years of manufacturing experience. If you need more product information and quotes, please contact us.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations