FR4 Epoxy Laminates in Power Systems: Key Roles & Engineering Benefits

The Role and Engineering Value of FR4 Epoxy Glass Fiber Laminates in Power Systems In modern power systems, equipmen...

The Role and Engineering Value of FR4 Epoxy Glass Fiber Laminates in Power Systems

In modern power systems, equipment is continuously evolving toward higher voltage levels, higher power density, compact design, and long-term reliable operation. These trends place stringent demands on insulation materials—not only must they provide stable electrical insulation, but they must also serve as load-bearing structural components.

Against this background, FR4 epoxy glass fiber laminate has become one of the most widely used composite insulation–structural materials in power systems.

I. The Fundamental Role of FR4 in Power Systems: More Than “Just an Insulation Board”

FR4 is often simply regarded as an insulation material. However, in real power equipment applications, its true role is far more comprehensive:FR4 functions simultaneously as an electrical insulation medium, a mechanical support structure, and a long-term operational reliability material.These three functions are inseparable in power system design.

II. Electrical Insulation Function: Electric Field Control and System Safety

Isolation of Live Conductors and Prevention of Breakdown

In transformers, switchgear, and power distribution equipment, conductors at different potentials are often arranged in close proximity.

Thanks to its high volume resistivity and dielectric strength, FR4 effectively isolates high- and low-voltage conductors within limited space, preventing failures caused by air breakdown, surface tracking, or flashover.

Stabilizing Electric Field Distribution and Reducing Partial Discharge

With stable dielectric properties and a dense internal structure, FR4 acts as an electric field grading and buffering medium:

Reduces electric field concentration at sharp edges

Lowers the risk of partial discharge

Slows insulation aging

This function is particularly critical in medium- and high-voltage power equipment.

III. Mechanical Support Function: The “Skeleton” of the Insulation System

Withstanding Electrodynamic and Thermal Stresses

During operation, power equipment is subjected to:

Electrodynamic forces generated by short-circuit currents

Thermal expansion and contraction caused by load fluctuations

FR4 combines high mechanical strength with excellent dimensional stability, enabling it to:

Securely support windings, busbars, and power modules

Prevent structural displacement that could compromise insulation clearances

Integration of Insulation and Structure

Compared with traditional designs that rely on metal structures plus additional insulation layers, FR4 allows:

Structural components to be inherently insulating

Reduced assembly complexity

Improved overall system reliability

This is a key reason why FR4 is extensively used in switchgear and power electronic equipment.

IV. Thermal Resistance and Long-Term Operational Stability

Adaptation to Continuous Thermal Stress

Power equipment typically operates 24/7 over long service lifetimes rather than in intermittent duty cycles.

FR4 provides:

F-class (155°C) thermal endurance or higher

High-Tg FR4 grades that retain mechanical and electrical stability at elevated temperatures

2. Resistance to Aging and Electric Arc Damage

During switching operations, overloads, or fault conditions:

FR4 exhibits good arc resistance

Flame retardancy can reach UL94 V-0

These properties are directly related to operational safety and fault containment.

V. How FR4 Functions in Typical Power Equipment

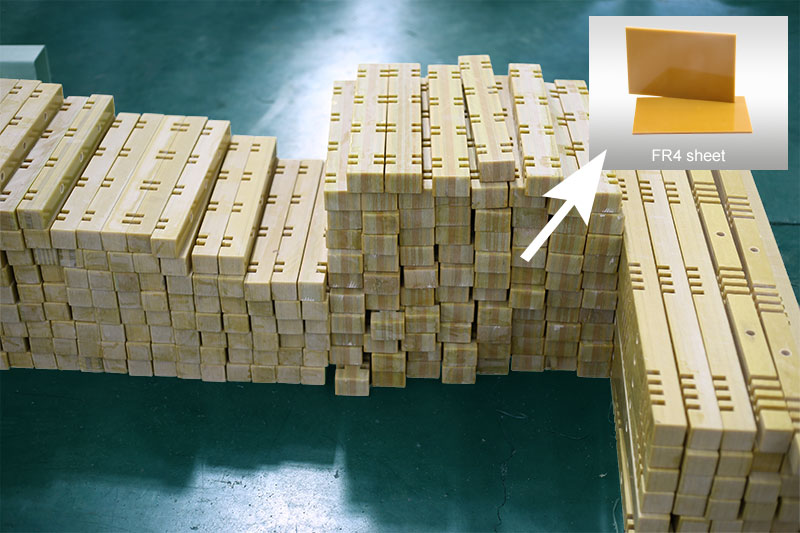

In Transformer Systems

FR4 is far more than a simple spacer. It plays a critical role in:

Maintaining winding geometry

Controlling insulation distances

Sharing mechanical stresses

Enhancing overall insulation system reliability

In dry-type transformers, FR4 is one of the core structural insulation materials.

In Switchgear and Distribution Cabinets

In these systems, FR4 is used to:

Provide phase-to-phase and phase-to-ground insulation

Support and insulate busbar systems

Act as a protective barrier for personnel safety

Its importance is especially evident in compact and modular switchgear designs.

In Renewable Energy and Power Electronics

In inverters, energy storage systems, and photovoltaic installations, FR4:

Supports high-power electronic modules

Electrically isolates high-voltage DC and AC circuits

Ensures both mechanical stability and electrical safety

VI. Performance Requirements for FR4 in Power Systems Are More Than “Basic Insulation”

In power system applications, the concern is not merely whether FR4 can insulate, but whether it can:

Remain stable over long periods

Perform reliably under humidity, vibration, and electrical stress

Exhibit predictable and controlled aging behavior

Therefore, power-grade FR4 typically requires:

Low moisture absorption

High CTI (Comparative Tracking Index)

High glass transition temperature (Tg)

Flame retardancy and arc resistance

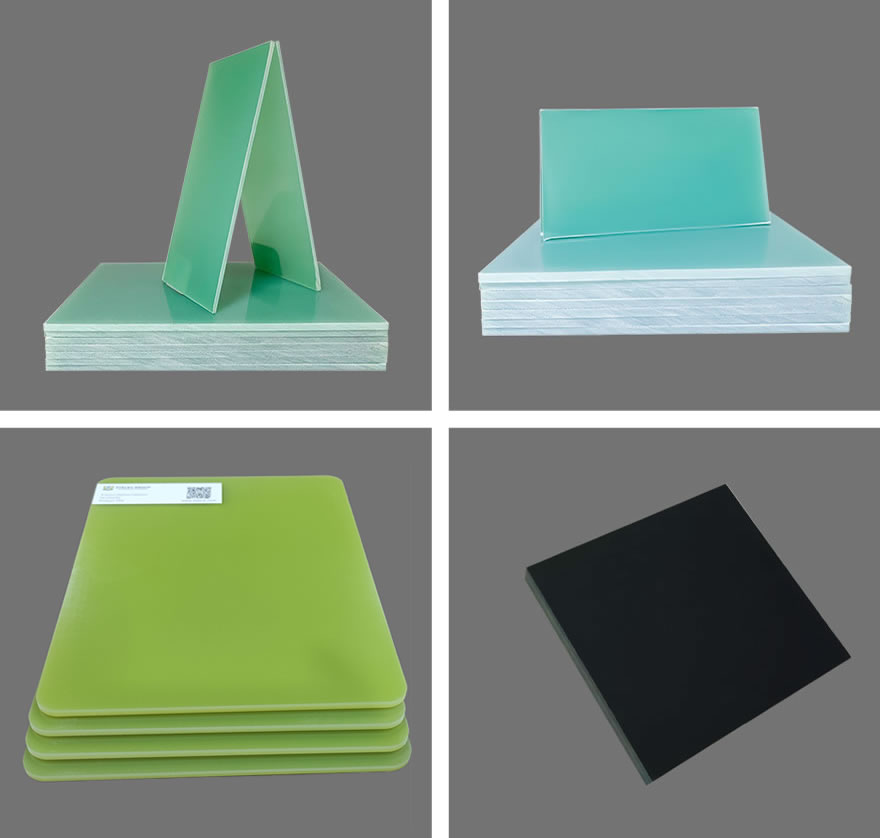

VII. Engineering Positioning of FR4 Compared with Other Insulation Materials

In power systems, insulation materials are not substitutes but complementary components with clearly defined roles:

FR4: Integrated insulation and structural support

G10 / G11: Higher mechanical strength or higher temperature resistance

Insulation paper and flexible laminates: Winding and interlayer insulation

Epoxy molded components: Complex, customized insulation structures

FR4 represents the best balance of performance, manufacturability, and cost efficiency.

VIII. An Engineer’s One-Sentence Summary

The value of FR4 in power systems lies not simply in its ability to insulate, but in its capability to reliably combine insulation, structure, and safety throughout long-term operation.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations