FR4 antistatic epoxy board Features and applications

Introduction to FR4 antistatic epoxy board FR4 antistatic epoxy board is a composite material made of epoxy resin as...

Introduction to FR4 antistatic epoxy board

FR4 antistatic epoxy board is a composite material made of epoxy resin as the base material and glass fiber cloth as the reinforcement material. It has stable antistatic properties by adding antistatic agents (such as carbon fiber, conductive filler, etc.). This material effectively solves the problem of static electricity accumulation while retaining the excellent mechanical properties and high temperature resistance of traditional FR4 epoxy board. It is widely used in high-precision electronics, communications, medical and other fields that are sensitive to static electricity. Its surface resistance is usually controlled within the range of 106∼109Ω106∼109Ω, which can not only avoid the damage of electrostatic discharge (ESD) to components, but also avoid the risk of short circuit due to excessive conductivity.

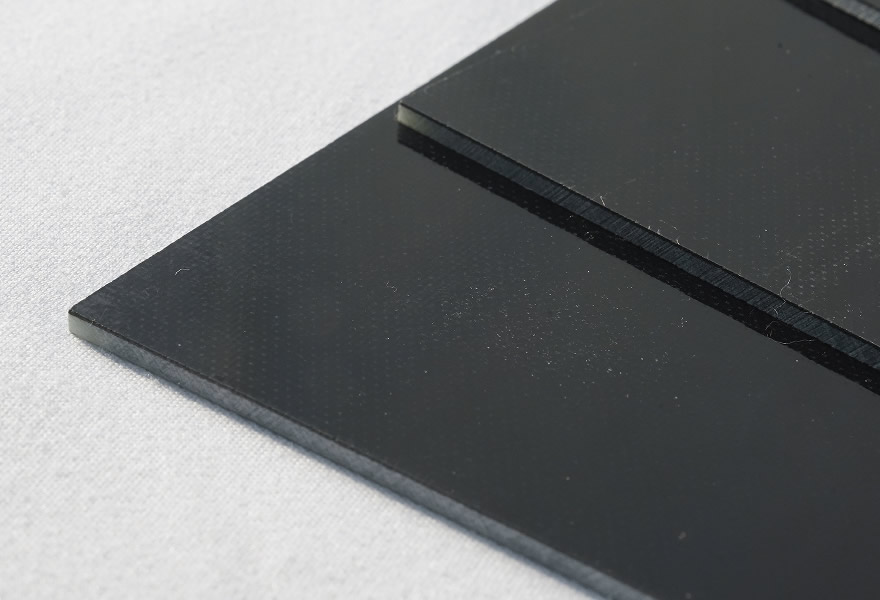

Double sided FR4 anti-static sheet

FR4 antistatic epoxy board Product Features

Antistatic performance: Stable surface resistance is achieved through modification process, which can quickly conduct away static electricity charge and prevent static electricity adsorption or discharge.

High mechanical strength: Glass fiber cloth gives it excellent bending strength, impact resistance and dimensional stability.

High temperature resistance: The long-term working temperature can reach above 130°C, and it can withstand higher temperatures (such as 180°C) in the short term, which is suitable for high temperature environment.

Chemical corrosion resistance: Good tolerance to chemicals such as acids, alkalis, and organic solvents.

Easy processing: Supports mechanical processing such as drilling, cutting, and milling, but it should be noted that the local anti-static performance may be affected after processing.

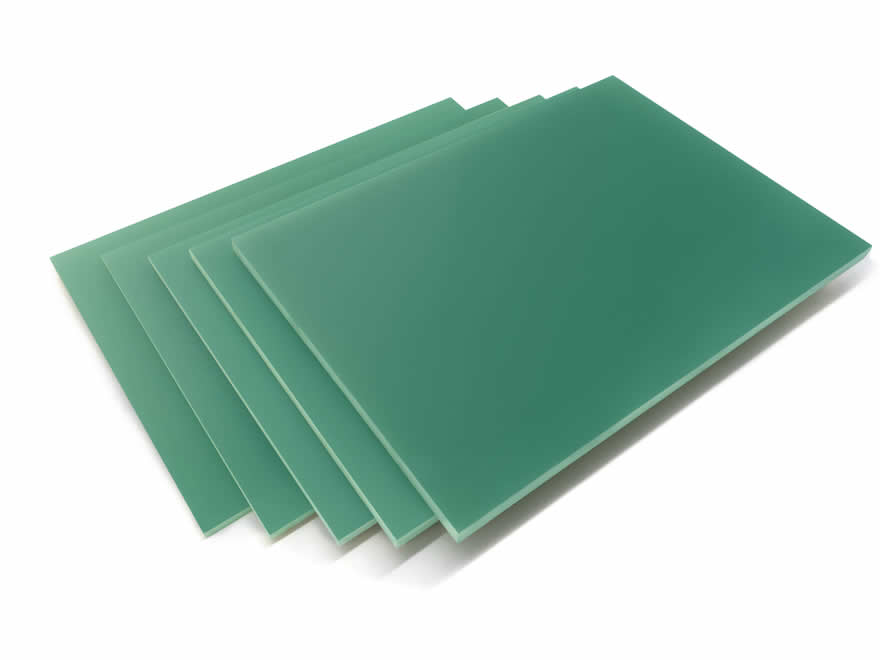

Single sided FR4 anti-static board

FR4 antistatic epoxy board Application

FR4 anti-static epoxy boards are mostly used in scenarios where electrostatic interference needs to be eliminated, such as:

Electronics industry: PCB test fixtures, semiconductor packaging equipment, and precision instrument operating tables.

Medical equipment: Insulating support components for highly sensitive medical testing instruments.

Aerospace: Anti-static isolation panels or brackets in electronic cabins.

Industrial automation: Protective structural parts for electrostatic sensitive areas of robots.

Differences between FR4 anti-static epoxy boards and ordinary FR4 epoxy boards

Differences in conductive properties:

Ordinary FR4 epoxy boards are insulating materials with a surface resistance usually higher than 1012Ω1012Ω, which is easy to accumulate static electricity.

The anti-static type is modified to reduce the surface resistance to 106∼109Ω106∼109Ω, and has controllable electrostatic dissipation capabilities.

Different application scenarios:

Ordinary FR4 is mostly used in pure insulation scenarios, such as transformer insulation gaskets, motor slot wedges, etc.

Antistatic type is specifically used in areas where electrostatic discharge needs to be avoided, such as chip testing, precision electronic assembly, etc.

Material composition adjustment:

Antistatic version needs to add conductive components (such as carbon fiber, metal oxide or permanent antistatic agent), which may slightly sacrifice some dielectric properties.

Post-processing:

Ordinary FR4 has little performance change after processing, while antistatic type needs to pay attention to cutting or drilling may damage the conductive network, and needs to restore performance through surface treatment (such as spraying antistatic coating).

How to choose and purchase FR4 anti-static board

FR4 antistatic epoxy board realizes the electrostatic protection function on the basis of traditional materials and is an indispensable functional material in the electronics manufacturing industry. The core difference between it and ordinary FR4 lies in the regulation of conductive properties. Users need to choose according to actual needs (such as electrostatic protection level, dielectric strength, cost). In high-frequency circuits or ultra-high voltage insulation scenarios, ordinary FR4 is still a better choice; in electrostatic sensitive environments, antistatic type can significantly improve equipment reliability.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 65 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first. Products are exported to Europe, America, Southeast Asia and other countries and regions.

If you are looking for fr4 antistatic sheets, please Contact us. we are a professional manufacturer of high-quality electrical insulation materials with more than 65 years of manufacturing experience.it can be customized according to the product specifications, thickness and purpose you need.

Contact us now to get detailed product information and quotation. We can also mail samples for free for your testing.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted