FR-4 materials in PCB Application and advantages

FR-4 materials is not only the core substrate material in PCB (printed circuit board) manufacturing, but also an impo...

FR-4 materials is not only the core substrate material in PCB (printed circuit board) manufacturing, but also an important guarantee for the stability and reliability of modern electronic products.

When choosing PCB board materials, FR-4 is often mentioned as the abbreviation for a type of glass fiber reinforced epoxy resin material. But strictly speaking, FR-4 is not a material name, but the fire resistance level of the material.

FR-4 material Definition

FR-4, full name Flame Retardant 4, is a glass fiber reinforced epoxy resin laminate material. It does not refer to a specific material, but a general term for a class of materials with specific fire resistance levels and compositions.

According to the classification standards of NEMA (National Electrical Manufacturers Association), FR represents that the material has flame retardant properties, and the number “4” represents its specific composition: epoxy resin as adhesive, electronic grade glass fiber cloth as reinforcing material, and the flame retardant level reaches UL94 V-0 standard.

FR-4 Material Characteristics

High mechanical strength:Glass fiber reinforcement gives FR-4 substrate excellent bending and impact resistance, and can withstand the stress caused by complex circuit layout.

Excellent electrical performance:FR-4 material has good electrical insulation performance, which can effectively prevent interference and short circuits between different circuits on the circuit board, ensuring the stability and reliability of signal transmission.

Good flame retardant performance: UL94 V-0 level flame retardant performance enables FR-4 material to quickly self-extinguish when encountering fire, greatly improving the safety of electronic products.

Good processing performance: FR-4 material is easy to drill, cut, bend and other processing operations, suitable for realizing complex multilayer board structures.

Moderate cost: Compared with other high-performance materials, the manufacturing cost of FR-4 material is relatively low, suitable for large-scale production.

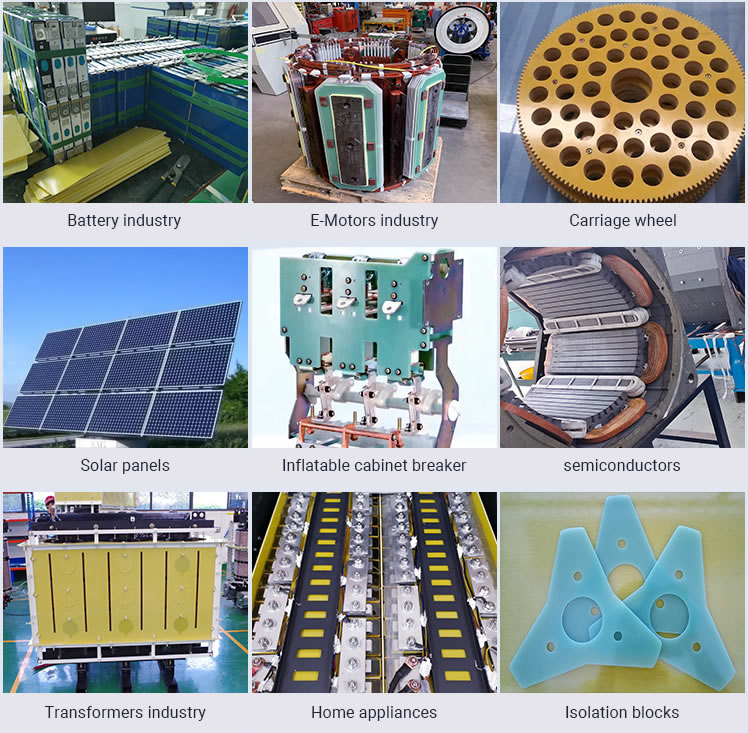

Application fields of FR-4 materials

Due to the many excellent properties mentioned above, FR-4 materials are widely used in the PCB manufacturing of various electronic products, including but not limited to:

Communication equipment: such as mobile phones, routers, switches, etc., these devices have extremely high requirements for the stability and electrical performance of circuit boards.

Computer hardware: key components such as motherboards, graphics cards, memory sticks, etc., FR-4 materials provide good electrical insulation and mechanical support.

Consumer electronics: such as TVs, audio, game consoles, etc., these products have strict requirements on the durability and safety of PCBs.

Automotive electronics: electronic control units, sensors, etc. in automobiles need to withstand various harsh environmental tests. FR-4 materials stand out with their excellent weather resistance and flame retardancy.

Medical equipment: medical equipment has extremely high requirements for the stability and reliability of circuit boards. FR-4 materials also play an important role in these fields.

Typical Applications and Material Recommendations

| Application | Key Requirements | Recommended FR-4 Type | Notes |

| Consumer Electronics (Smartphones, TVs) | Cost-effective, standard performance | Standard Tg FR-4 (Dk=4.5) | Common thickness: 0.8–1.6 mm |

| Automotive Electronics (ECUs, ADAS) | High heat resistance, vibration resistance | High Tg FR-4 (Tg≥170°C) | Requires AEC-Q200 reliability tests |

| High-Frequency Circuits (5G Antennas) | Low loss, stable Dk | Low Dk/Df FR-4 (e.g., FR408HR) | Pair with high-frequency foil (RTF) |

| Servers/Data Centers | High-speed signals, heat resistance | High-speed modified FR-4 (e.g., IT-968G) | Supports 56 Gbps PAM4 signaling |

| Industrial Power Modules | High-voltage insulation, arc resistance | High CTI FR-4 (CTI≥600V) | Critical for PV inverters |

Manufacturing process of FR-4 materials

The manufacturing process of FR-4 materials is relatively complex, mainly including the following steps:

1.Resin preparation: high-quality epoxy resin is selected as the adhesive for precise proportioning and mixing.

2.Substrate gluing: The formulated epoxy resin is evenly coated on the electronic grade glass fiber cloth.

3.Stacking and lamination: Multiple layers of resin-coated glass fiber cloth are stacked together and treated with high temperature and high pressure to form a dense laminate.

4.Trimming, inspection and packaging: The laminate is trimmed to ensure dimensional accuracy, and strict quality inspection is carried out before packaging.

FR-4 material, as the core substrate material in PCB manufacturing, occupies an important position in the electronics manufacturing industry with its excellent mechanical strength, electrical properties, flame retardant properties, good processing performance and cost-effectiveness.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted