Fiberglass Wound Tubes in Dry-Type Transformers:Applications & Selection

Applications in Dry-Type Transformers Since dry-type transformers do not use insulating oil and typically operate i...

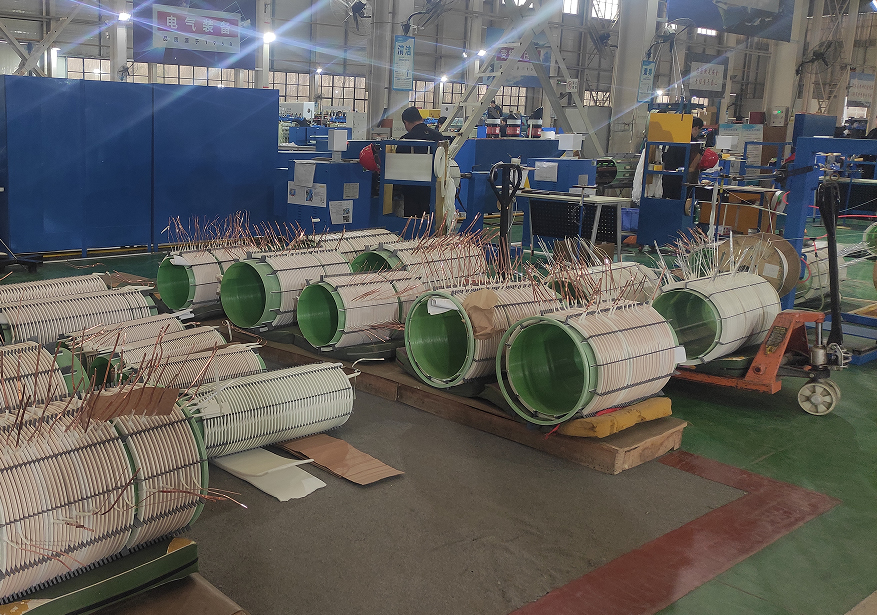

Applications in Dry-Type Transformers

Since dry-type transformers do not use insulating oil and typically operate in air or resin-cast environments, insulating materials must have higher requirements for heat resistance, moisture resistance, and flame retardancy.

Fiberglass wound tubes are commonly used in:

Insulating supports for HV and LV windings

Provide electrical isolation and mechanical support, ensuring safe spacing between turns and layers.

Lead bushings / conductor insulation sleeves

Protect winding leads, withstand electrical stress, and prevent discharge.

Winding reinforcement and structural supports

Used as end reinforcement or fastening components, improving resistance to short-circuit forces.

Insulation cylinders / spacers

Maintain insulation and cooling gaps between windings and between winding and core.

Key Selection Factors

1.Resin System

Epoxy resin system is preferred for its excellent electrical performance, suitable for the high insulation requirements of dry-type transformers.Must meet flame-retardant, low-smoke, and low-toxicity standards (e.g., UL94 V-0).

2.Thermal Class

Typically Class H (180°C) or higher, with some high-end designs requiring Class C (220°C).

3.Electrical Properties

High dielectric strength (≥10 kV/mm) to avoid partial discharge between windings.High volume resistivity, arc resistance, and corona resistance.

4.Mechanical Properties

Excellent compressive, flexural, and impact strength to withstand electrodynamic forces.Dimensional stability to avoid deformation under thermal cycling.

5.Environmental Adaptability

Low water absorption to maintain insulation in humid air.Flame-retardant, moisture-proof, and mildew-resistant, suitable for indoor and basement installation.

Recommended Specifications (Reference)

Material: Epoxy fiberglass wound tube (E-glass + Epoxy).

Thermal Class: H (180°C) or C (220°C).

Flame Retardancy: UL94 V-0 or equivalent standard.

Dielectric Strength: ≥10 kV/mm (in air).

Mechanical Strength: Flexural ≥ 250 MPa; Compressive ≥ 300 MPa.

Water Absorption: ≤0.2%.

Surface Quality: Smooth, free of bubbles or cracks; inner wall suitable for conductor installation.

Application Table of Fiberglass Wound Tubes in Dry-Type Transformers

| Application Part | Function | Recommended Selection Criteria |

|---|---|---|

| Coil lead insulation sleeve | Protects conductors, prevents electrical discharge and mechanical damage | Epoxy/E-glass system; F/H class thermal resistance; high dielectric strength; wear resistance |

| Inter-turn support / insulation spacer | Maintains inter-turn distance, prevents short circuit and displacement | High mechanical strength (≥250 MPa); good dimensional stability; low water absorption |

| Insulating cylinder / liner tube | Provides main insulation barrier, enhances electrical safety | High dielectric strength (≥10 kV/mm); heat resistance ≥155℃; low dielectric loss |

| Tie rod / fastening element | Withstands short-circuit forces and mechanical stress, stabilizes coil structure | High compressive/flexural strength; fatigue resistance; epoxy wound thick-wall type |

| End support & spacer | Ensures coil cooling ducts/air channels remain clear, improves heat dissipation | Customizable dimensions; heat-resistant without deformation; low moisture absorption |

| Core-to-coil insulation barrier | Enhances insulation level, prevents partial discharge | High voltage endurance; precise dimensions; excellent dielectric properties |

Summary:

In dry-type transformers, fiberglass wound tubes mainly serve electrical insulation, mechanical reinforcement, and heat dissipation support.

Selection Principle: Prefer epoxy/E-glass wound tubes, ensuring F/H class thermal resistance (155–180℃), high dielectric strength, and superior mechanical strength, while tailoring dimensions and properties to the specific application part.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations