Fiberglass Filament Wound Tubes for Power Equipment: Applications and Selection Guide

Introduction to Glass Fiber Filament Wound Tubes Glass fiber filament wound tubes are composite insulating materials...

Introduction to Glass Fiber Filament Wound Tubes

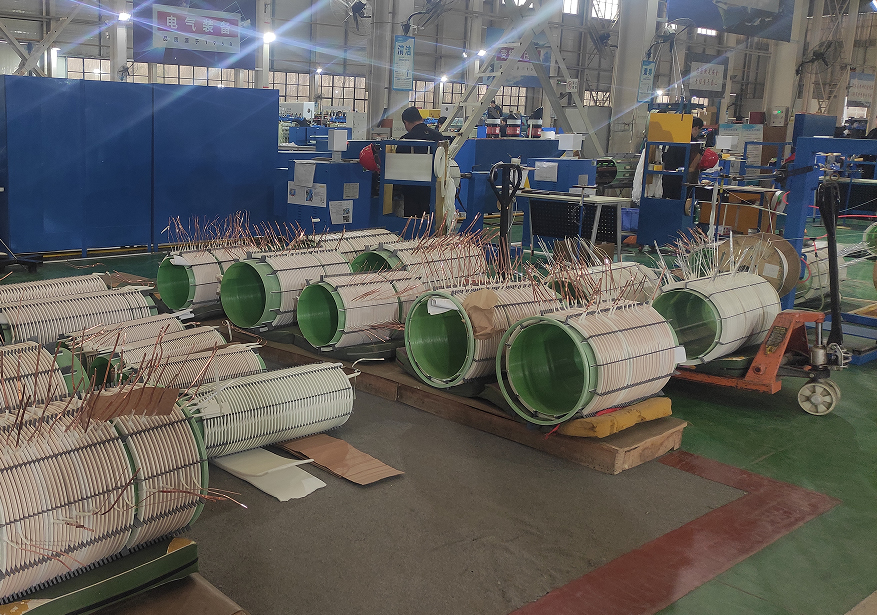

Glass fiber filament wound tubes are composite insulating materials made from alkali-free glass fiber yarns impregnated with thermosetting resins such as epoxy or phenolic resin. They are manufactured by filament winding on a mold, followed by high-temperature curing.

The fibers are arranged in both circumferential and axial directions, forming a dense and uniform structure. This gives the tubes excellent mechanical strength, electrical insulation, heat resistance, and chemical resistance.

I. Application Areas and Typical Positions

| Equipment Category | Application Positions | Main Functions |

|---|---|---|

| Transformer | Insulating support tubes, lead sleeves, tie rods, press plates | Provide insulation and support, withstand electromagnetic and mechanical stress |

| Reactor / Current Transformer | Coil skeletons, insulating sleeves, support components | Ensure inter-turn and ground insulation, enhance structural stability |

| Switchgear / Circuit Breaker | Busbar support tubes, insulating spacers, operating rods | High insulation strength, arc resistance, improve operating safety |

| Power Capacitor | Internal supports, insulating fixing parts | Dimensional stability, reliable insulation, lightweight and strong |

| Power Generation Equipment | Stator coil skeletons, insulating tubes, structural supports | Withstand high temperatures, ensure long-term reliable insulation |

| New Energy Equipment | Photovoltaic inverters, energy storage systems, traction motors | Provide insulation and support, impact resistance, moisture and corrosion resistance |

II. Selection Guidelines

1. Electrical Properties

Dielectric Strength: ≥10–20 kV/mm, sufficient for rated voltage class.

Volume Resistivity: ≥10^12 Ω·cm, ensuring long-term insulation.

Arc and Tracking Resistance: Suitable for high-voltage switchgear and circuit breakers.

2. Mechanical Properties

Flexural Strength: ≥300 MPa, to withstand electromagnetic and mechanical stress.

Compressive Strength: ≥250 MPa, for support and fixing components.

Low Density: Lightweight, ideal for replacing metal parts.

3. Thermal Resistance

Class F (155℃): Commonly used in transformers and switchgear.

Class H (180℃): For generators, traction motors, and high-temperature conditions.

Above 200℃: Custom options available for special applications.

4. Environmental Resistance

Moisture Resistance: Suitable for outdoor and humid environments.

Chemical Resistance: Applicable in energy storage and photovoltaic equipment.

Aging and Fatigue Resistance: Ensure long service life.

5. Dimensions and Processing

Diameter Range: Commonly φ10 mm – φ600 mm, larger sizes customizable.

Wall Thickness: 2 mm – 20 mm (depending on load and insulation requirements).

Machining Options: Turning, grinding, drilling, tapping for precise assembly.

III. Recommended Selection (Application – Parameters)

| Application Scenario | Recommended Thermal Class | Suggested Properties |

|---|---|---|

| Transformer Lead Sleeve | Class F 155℃ | Dielectric strength ≥15 kV/mm; compressive strength ≥250 MPa |

| Reactor Coil Skeleton | Class F/H | High insulation, moisture resistance, dimensional stability |

| Switchgear Busbar Support | Class H 180℃ | Arc resistance; flexural strength ≥300 MPa |

| Power Capacitor Fixing Part | Class F 155℃ | Lightweight, strong, high dimensional accuracy |

| Generator Stator Skeleton | Class H 180℃ | High temperature resistance, reliable insulation, fatigue resistance |

| PV / Energy Storage Inverter | Class H or above | Environmental resistance; insulation ≥10^12 Ω·cm |

Summary

In power equipment, glass fiber filament wound tubes serve mainly as insulation, support, fixation, and load-bearing components.

Selection should comprehensively consider electrical properties (voltage class), mechanical strength (load requirements), environmental adaptability (heat, moisture, corrosion resistance), and dimensional accuracy, to ensure long-term safe and stable operation.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations