DMD Insulation paper:Adaptability Advantages & Application Logic

Composition of DMD insulation paper DMD insulation paper (Dacron–Mylar–Dacron) is a three-layer flexible composite...

Composition of DMD insulation paper

DMD insulation paper (Dacron–Mylar–Dacron) is a three-layer flexible composite made by bonding polyester non-woven fabric on both sides of a polyester film through high-temperature lamination. With a long-term thermal class of Class F (155 °C), DMD has become one of the most widely used soft insulation materials in motors, dry-type transformers, and reactors. Its strong suitability comes from its balanced structure, stable performance, and excellent processing compatibility.

This article analyzes DMD insulation from two perspectives: adaptability advantages and application logic.

1. Core Adaptability Advantages of DMD Insulation Materials

Structural Adaptability: A Balanced Composite Architecture

DMD adopts a three-layer structure:

Polyester film (PET Film)

Provides high dielectric strength and ensures stable insulation between layers and turns.

Polyester non-woven fabric (PET Fleece)

Offers mechanical support, tear resistance, and flexibility, preventing cracking during bending, insertion, or wrapping.

Thermal lamination process

Creates a unified material that combines both flexibility and structural rigidity.

The synergy among the three layers is the fundamental reason why DMD is suitable for multiple insulation locations within electrical equipment.

Thermal Adaptability: Covers Standard Motor and Transformer Requirements

With its Class F (155 °C) thermal rating, DMD is ideal for:

Small and medium motors

Dry-type distribution transformers

Reactors and inductors

It withstands both short-term temperature rises and long-term thermal loads, ensuring stable performance throughout device operation.

Processing Adaptability: Easy to Fabricate, Form, and Impregnate

The non-woven layers make DMD processing-friendly:

Excellent for die-cutting (slot liners, phase insulation, pads)

Suitable for wrapping and winding as insulation tape

Strong varnish absorption, enhancing mechanical strength after curing

Compared with pure films or rigid laminates, DMD offers greater tolerance and flexibility during manufacturing.

Electrical Adaptability: Meets Requirements of Most Low- and Medium-Voltage Devices

Thanks to the polyester film core, DMD provides:

High breakdown voltage

Stable insulation resistance

Strong tolerance for uneven electric fields

This makes DMD ideal for electrical systems operating within the 400V–35kV range.

Mechanical Adaptability: Withstands Electromagnetic Force, Vibration, and Slot Insertion

The non-woven layers give DMD outstanding:

Tear resistance

Shock absorption

Compression and resilience

DMD remains intact under coil insertion forces, transformer end-pressure, and reactor vibration.

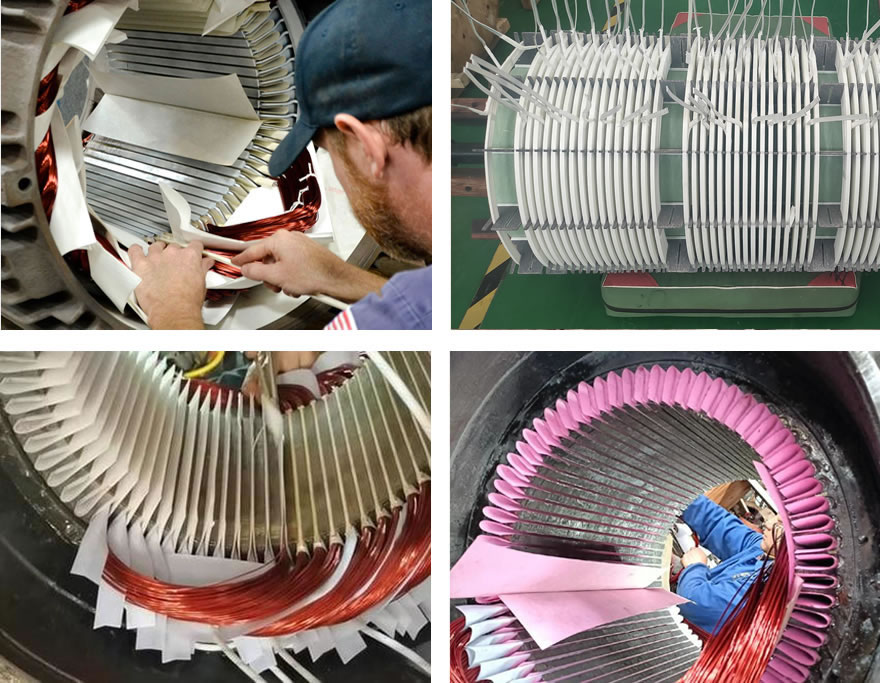

2. Logical Application Principles of DMD in Electrical Equipment

DMD is not randomly placed inside equipment—it fulfills clear insulation functions. Its application follows three engineering-driven logics:

“Electric Field Distribution” Logic: Using the Film Layer for Dielectric Strength

Where high dielectric strength is required, the polyester film acts as the main insulation:

Motor slot insulation — isolates coil conductors from the laminated core

Transformer interlayer insulation — controls voltage gradients within HV windings

Application logic:

Higher electric field → film-based insulation → choose DMD

“Mechanical Buffering” Logic: Using the Non-woven Layer to Absorb Stress

Where bending, compression, or mechanical force occurs:

Slot insertion areas in motors

Spacer pads in dry-type transformers

Coil displacement zones in reactors

DMD’s non-woven structure absorbs stress and prevents material failure.

Application logic:

Higher mechanical stress → fiber-based buffering → choose DMD

“Varnish Bonding” Logic: Enhancing System Strength Through Impregnation

DMD absorbs varnish well, which:

Strengthens the coil structure after impregnation

Enhances bonding in VPI-treated dry-type transformers

Prevents delamination or blistering during curing

Application logic:

Requiring strong bonding with insulating varnish → choose DMD

3. Conclusion: DMD’s Adaptability Comes From Balanced Structure–Performance–Process Integration

Although DMD is not the highest-temperature or highest-dielectric-strength material, it remains one of the most adaptable and widely used insulation materials.

Its value lies in:

Comprehensive structure (film + non-woven fabric)

Balanced properties (mechanical, electrical, thermal)

High processing compatibility (die-cut, wrap, varnish impregnation)

Cost-effectiveness for mass production

For motors, transformers, and reactors, DMD continues to be a fundamental material that aligns with the trends of equipment miniaturization, lightweight design, and automated manufacturing.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations