DDP insulation paper for Inter-Layer Insulation in Oil-Immersed Transformers :Selection Guide

DDP Paper for Inter-Layer Insulation in Oil-Immersed Transformer Windings 1. Scope of Application Inter-layer insul...

DDP Paper for Inter-Layer Insulation in Oil-Immersed Transformer Windings

1. Scope of Application

Inter-layer insulation of oil-immersed transformer windings

Voltage levels: 10 kV – 220 kV

Winding types: cylindrical, disc (continuous), multi-layer

Base material compatible with oil-impregnated insulation systems (mineral oil or ester oil)

2. Selection Principles

Selection Based on Voltage Level and Insulation Margin

The thickness of DDP insulation paper should ensure that inter-layer insulation strength meets operating voltage plus safety margin.

Recommended thickness values:

| Voltage Level | Recommended DDP Paper Thickness |

|---|---|

| ≤10 kV | 0.13 / 0.18 mm |

| 35 kV | 0.20 / 0.25 mm |

| ≥110 kV | ≥0.25 mm |

Principle: Higher voltage → thicker DDP paper ; also consider mechanical short-circuit force requirements.

Selection Based on Short-Circuit Force and Mechanical Stress

Large-capacity transformers, high short-circuit current systems, and compact windings → choose thicker DDP insulation paper with higher adhesion strength.

Uniform and regular resin dot distribution → ensures inter-layer shear strength.

Typical inter-layer adhesion strength ≥ 400 kPa (adjustable according to design requirements).

Selection Based on Oil Channels and Heat Dissipation

Resin dot coverage should be moderate: 15%–30%

Avoid continuous resin layers → ensure oil channels remain open

Ensure uniform oil impregnation → stable insulation performance

Selection Based on Winding Process and Curing Conditions

Resin dot melting temperature must match the winding drying and curing process

Insufficient curing → inadequate inter-layer bonding

Over-curing → paper embrittlement and accelerated thermal aging

Selection Based on Thermal Performance and Aging

Compatible with oil-immersed transformer insulation class A / F

Stable performance at long-term oil temperatures of 90–110 °C

Short-term thermal resistance ≥ 120 °C

Resistant to thermal aging: no embrittlement, no delamination, no powdering

Selection Based on Oil Compatibility

Compatible with mineral oil or ester oil

Does not affect oil dielectric loss (tanδ)

Good oil absorption → prevents dry spots that could cause breakdown

Selection Based on Winding Structure

Cylindrical winding → ensures radial stability

Disc (continuous) winding → ensures axial stability

Compact winding → improves mechanical strength and reduces the need for additional reinforcement

3. Selection Summary

The selection of DDP insulation paper should comprehensively consider voltage level, short-circuit force, inter-layer adhesion, oil impregnation, thermal stability, and process compatibility. Proper selection ensures reliable, safe, and durable inter-layer insulation in oil-immersed transformer windings.

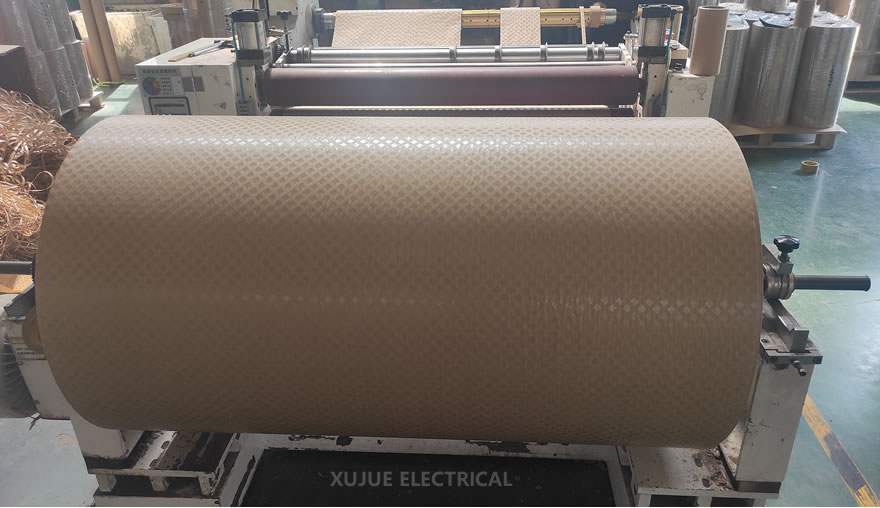

4. Manufacturer selection and quotation

XUJUE ELECTRICAL is a professional DDP transformer insulation material manufacturer, since 1958., ensuring reliable quality and stable performance. Throughout customer service, Xujue’s professional team can provide suitable specifications and models of DDP insulation paper based on the specific requirements and application scenarios of transformer manufacturing. Whether for small batches or large-scale production, Xujue responds promptly, offering attentive service and high-quality products.

Contact Xujue Electrical now to get detailed product information and quotation. We can also mail samples for free for your testing.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations