Application of UPGM203 in Generators

What Is UPGM203 Material? UPGM203 is a glass fiber reinforced unsaturated polyester molding laminate, known for its ...

What Is UPGM203 Material?

UPGM203 is a glass fiber reinforced unsaturated polyester molding laminate, known for its high mechanical strength, electrical insulation, and heat resistance.

It is made by impregnating non-alkali glass mat with unsaturated polyester resin and curing under high temperature and pressure.

This material is widely used in motors, generators, transformers, and switchgear.

Standard: IEC 60893 / NEMA GPO-3

Thermal Class: B (130°C) to F (155°C)

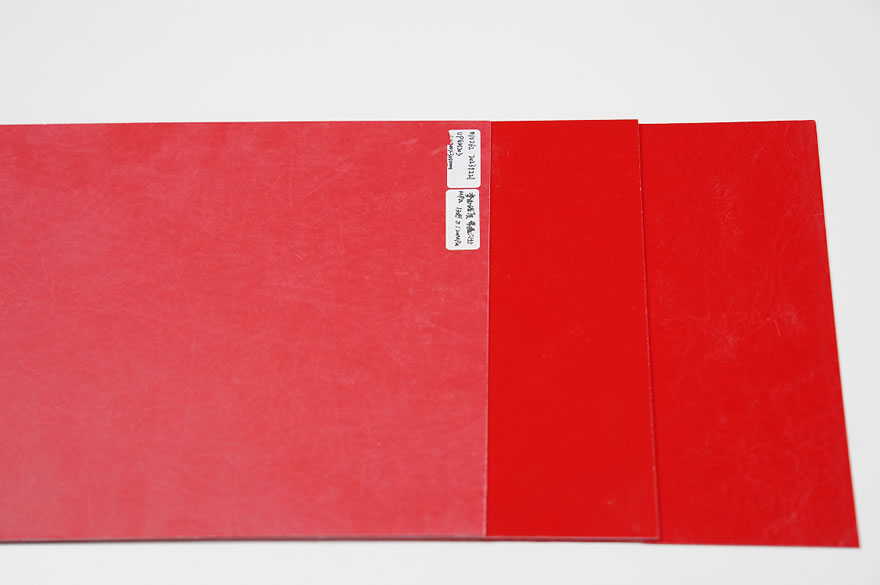

Color: Red or light pink

Flame Retardant: UL94 V-0

Main Applications of UPGM203 in Generators

UPGM203 performs critical insulating and structural roles inside both synchronous and asynchronous generators.

Below are the key parts where UPGM203 is commonly used:

| Component | Function | Required Properties | Benefits of UPGM203 |

|---|---|---|---|

| Stator End Support Plate | Supports stator coils and withstands mechanical stress | High strength, heat resistance | Prevents coil deformation and ensures long-term insulation reliability |

| Slot Wedge / Slot Liner | Holds coils firmly in slots | Dielectric strength, stability | Reduces movement and vibration of windings |

| Phase Separator | Separates different phase windings | High dielectric insulation | Enhances phase-to-phase insulation safety |

| Terminal Board | Mounts and isolates terminal connections | Flame resistance, moisture proof | Prevents arcing and leakage current |

| Insulating Spacer & Support Blocks | Provides mechanical support | High rigidity and electrical insulation | Replaces metal supports to eliminate short-circuit risk |

Performance Advantages of UPGM203

1. Excellent Electrical Insulation

Dielectric strength ≥ 14 kV/mm

High surface resistivity prevents leakage current and corona discharge

2. Strong Mechanical Strength

Flexural strength ≥ 150 MPa

Maintains stability even under high temperature and mechanical vibration

3. High Heat and Flame Resistance

UL94 V-0 flame retardant grade

Long-term operation temperature up to 155°C

4. Moisture and Chemical Resistance

Performs well in humid or oil-filled generator environments

Resists acid, alkali, and oil corrosion

Case Studies

1. 1000 kW Synchronous Generator

UPGM203 is used as the stator end support plate, replacing traditional epoxy board.

It reduces weight by 15% and increases the thermal class to F level, ensuring stable long-term performance.

2. Diesel Generator Terminal Insulation Board

UPGM203 provides excellent dielectric strength and flame resistance, extending operational life by 30%.

Alternative and Complementary Materials

| Material | Comparison | Typical Use |

|---|---|---|

| GPO-3 Sheet | Similar to UPGM203, lower cost | General motor and control cabinet parts |

| G10 / FR4 Epoxy Board | Higher mechanical strength, higher cost | High-speed or precision generators |

| DMC Molding Parts | Suitable for complex shapes | Small and medium-sized motor components |

Why Choose Xujue Electrical UPGM203?

Xujue Electrical is a professional manufacturer of insulation materials in China, offering a full range of UPGM203 sheets and molded parts.

Our products are certified, customizable, and widely used by generator OEMs worldwide.

Factory-direct supply, guaranteed quality

Custom machining for insulation components

Fast delivery and export-ready packaging

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations