Application of G11 Epoxy Sheet in High-Voltage Motor Slot Wedges

Introduction to G11 epoxy sheet G11 epoxy glass fiber sheet is a high-performance insulating material made from wove...

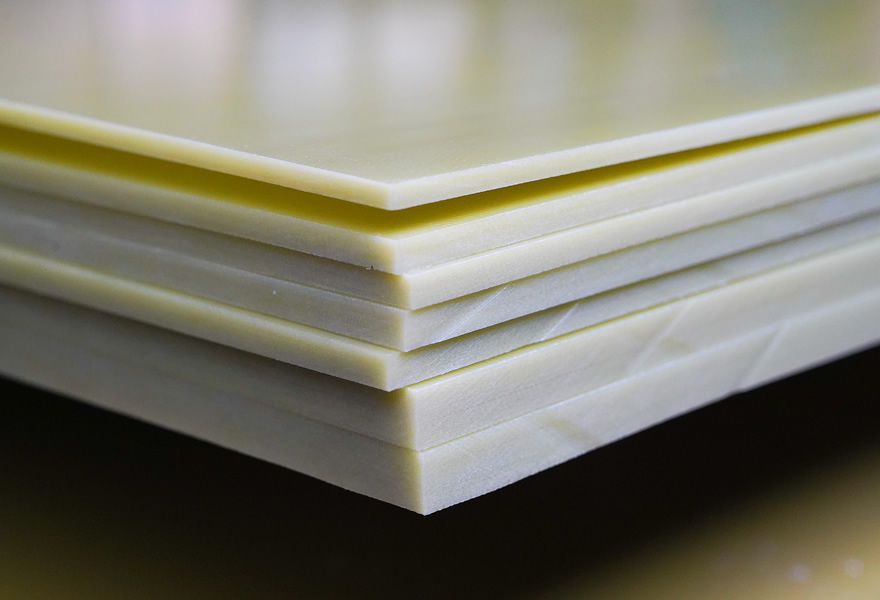

Introduction to G11 epoxy sheet

G11 epoxy glass fiber sheet is a high-performance insulating material made from woven fiberglass cloth impregnated with epoxy resin and cured under high temperature and pressure. With a thermal class of H (180°C) and excellent electrical and mechanical properties, G11 is one of the most widely used materials for slot wedges in high-voltage motors (6 kV, 10 kV, 13.8 kV, etc.).

Slot wedges play a critical role in securing the stator windings inside the slots, maintaining mechanical stability, and preventing partial discharge. G11 offers a combination of strength + heat resistance + dielectric reliability, making it ideal for demanding motor environments.

1. Why G11 Epoxy sheet Is Ideal for High-Voltage Motor Slot Wedges

1.1 High Mechanical Strength

Flexural strength: 350–400 MPa

Excellent resistance to vibration and electromagnetic forces

Prevents coil movement and mechanical fatigue

This ensures long-term stability of stator windings during heavy load and start-stop cycles.

1.2 Excellent Electrical Insulation

Dielectric strength: ≥20 kV/mm

Strong resistance to partial discharge and electrical stress

Stable performance in high-voltage environments up to 13.8 kV

G11 helps reduce insulation failures at the coil-slot interface.

1.3 High Temperature Resistance (Class H 180°C)

Maintains mechanical integrity under high thermal loads

Low thermal aging rate

Performs well in motors operating under high-frequency starts and harsh environments

This gives G11 a clear advantage over G10, FR4, DMC, and polyester-based materials.

1.4 Low Water Absorption & Dimensional Stability

Water absorption ≤0.1%

Stable dimensions even in humid, oily, or high-temperature environments

Easy to machine into different slot wedge profiles

This ensures tight coil compression without expansion or deformation.

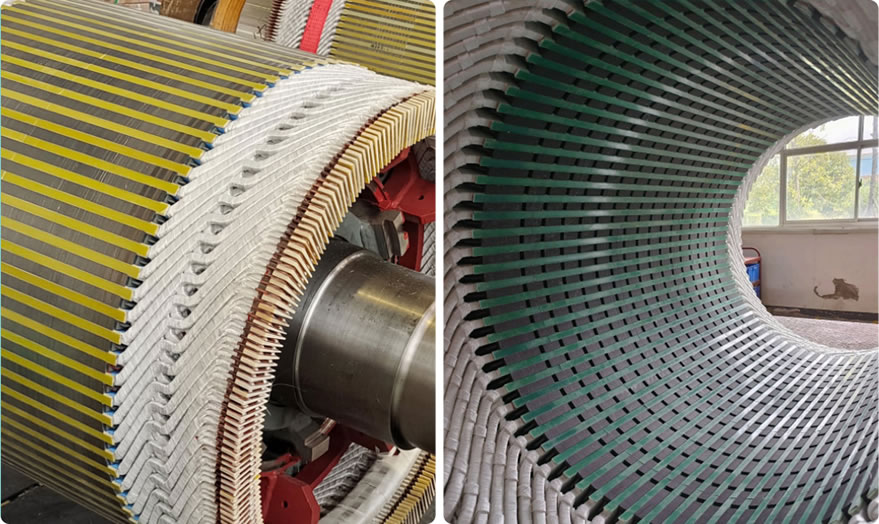

2. Typical Applications in High-Voltage Motors

2.1 Stator Slot Wedges for 6 kV, 10 kV, 13.8 kV Motors

G11 keeps windings firmly in the stator slots while resisting electrical, mechanical, and thermal stress.

2.2 Wind Turbine Generators

Requires high strength, humidity resistance, and thermal stability—G11 matches these needs perfectly.

2.3 Industrial High-Voltage Motors

Used in:

Pumps

Compressors

Fans

Mining motors

Petrochemical motors

These motors run in harsh conditions where G11 offers superior durability.

2.4 Motor Repair, Rewinding and Upgrading

Widely used in service centers as a replacement for:

Wooden wedges

DMC wedges

Standard epoxy sheets

G11 significantly enhances insulation reliability and motor lifespan.

3. Technical Specifications of G11 Slot Wedge Material

Property Typical Value

Composition Epoxy resin + fiberglass cloth

Thermal Class Class H (180°C)

Dielectric Strength ≥20 kV/mm

Flexural Strength 350–400 MPa

Water Absorption ≤0.1%

Machinability Good (cutting, CNC milling, chamfering)

Available Profiles Straight, dovetail, T-type, wave-shaped wedges

Customized shapes and sizes can be produced according to drawings.

4. Advantages of Using G11 for Slot Wedges

Improves overall insulation system of the motor

Enhances coil fixation, reducing vibration and abrasion

Extends motor service life under high voltage and high temperature

Stable performance in humid or chemically aggressive environments

Excellent mechanical stability and precise dimensions

These advantages make G11 a preferred material for modern high-voltage motor manufacturers and maintenance providers.

5. Alternative Materials (When Appropriate)

Material Notes

G10 Lower thermal rating; suitable for medium-voltage motors

FR4 Good electrical properties but lower heat resistance

DMC wedges Cost-effective but not suitable for severe thermal cycles

Phenolic laminate Lower mechanical strength and aging resistance

For mission-critical applications, G11 is the superior choice due to its balanced performance.

If you are looking for G11 epoxy fiberglass sheets, please contact Xujue Electrical and provide the product specifications, thickness and purpose you need, you can get detailed product information and quotation, and also send samples free of charge

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-28 2026Pultruded Epoxy Rod Applications in Power Equipment

- 02-27 2026How to Select the Thickness of Transformer Crepe Paper

- 02-26 2026ESD FR4 sheet vs Standard FR4 Epoxy Sheet

- 02-25 2026Phenolic cotton cloth rod applied to transformers

- 02-24 20262026 Global Transformer Boom Fuels Rising Demand for Electrical Insulation materials

- 02-24 2026XUJUE ELECTRICAL Officially Resumes Operations