Application of G10 sheet in wind turbines

G10 in Wind Turbines G10 sheet (also known as G10 epoxy glass fiber laminated sheet) is a composite material made fr...

G10 in Wind Turbines

G10 sheet (also known as G10 epoxy glass fiber laminated sheet) is a composite material made from fiberglass cloth and epoxy resin laminated under high temperature and pressure. It is renowned for its outstanding mechanical strength, excellent electrical insulation, superior moisture resistance, and resistance to chemical corrosion. These properties make it an ideal material for many critical components in wind power systems.

The working environment of wind turbines is extremely harsh: continuous vibration at high altitude, large temperature fluctuations, humidity, salt spray (for offshore turbines), and intense UV radiation. Therefore, the reliability requirements for materials are exceptionally high. The following characteristics of G10 perfectly meet these demands:

High strength-to-weight ratio: Very strong yet lightweight, helping to reduce overall system weight.

Excellent insulation: Ensures the safe operation of high-voltage electrical systems.

Dimensional stability: Resists deformation or shrinkage under varying temperature and humidity.

Fatigue and vibration resistance: Withstands long-term vibrations caused by blade rotation and wind loads.

Specific Applications of G10 in Wind Turbines

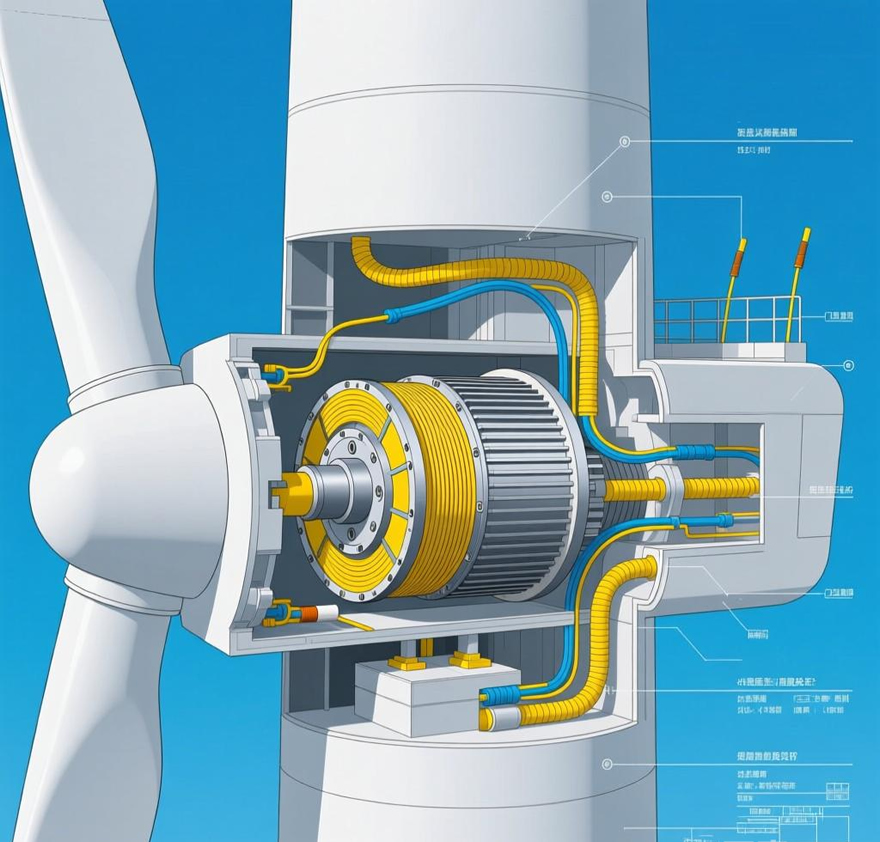

1. Inside the Generator – Insulation Components (the most critical application)

At the heart of a wind turbine is a massive generator (typically a permanent magnet synchronous generator or doubly-fed induction generator), with internal voltages reaching several kilovolts. G10 plays a vital role here as both an insulating and structural support material.

Insulating blocks and brackets: Used to secure and isolate the large stator windings and rotor poles. These components must endure strong electromagnetic forces, vibrations, and high temperatures while maintaining absolute insulation to prevent short circuits. The high dielectric strength and mechanical strength of G10 ensure long-term reliable operation.

Slot wedges: Used to firmly lock the stator windings in place within the slots, preventing vibration or displacement under electromagnetic forces.

End support rings and rods: Provide support and binding for windings at the generator ends, requiring both high mechanical strength and insulation.

2. Control Systems and Transformers

PCB circuit boards: Control cabinets, pitch systems, and converters in wind turbines all rely on printed circuit boards, typically made from FR-4 (flame-retardant G10). These serve as the wiring platform and insulating base.

Transformer insulation spacers: Transformers inside the nacelle or tower often use G10 sheets as insulating spacers and support components.

3. Blade Structure

Internal reinforcements and shear webs: In some blade designs, G10 sheets are used as internal reinforcements or part of the shear web structure, enhancing torsional and bending stiffness while keeping weight low.

4. Other Structural and Auxiliary Components

Brush holders and brackets: In brushed generator designs, G10 is often used for brush holders due to its insulation and heat resistance.

Sensor brackets and insulating bases: Provide lightweight, rigid, and insulating platforms for various sensors (e.g., vibration, temperature).

Cable supports and insulating barriers: Manage and support high-voltage cables in the nacelle and tower, preventing wear and short circuits.

Why Choose G10 Over Metals or Other Materials?

Versus metals (aluminum, steel):

Insulation: Metals are conductive and unsuitable for insulating applications.

Weight: G10 is significantly lighter, reducing nacelle weight and structural load.

Non-magnetic: Does not interfere with the generator’s electromagnetic fields.

Corrosion resistance: Unlike metals, G10 does not rust, making it ideal for offshore turbines exposed to salt and humidity.

Versus other plastics (nylon, PEEK):

Cost-effectiveness: Provides high mechanical and insulating performance at a much lower cost than high-end plastics like PEEK.

Balanced performance: Offers superior strength, rigidity, creep resistance, and dimensional stability compared to common plastics like nylon or ABS.

Conclusion

G10/FR-4 is an indispensable engineering material in wind turbines. While it may not be as visible as blades or the main shaft, it works as a “hidden hero,” embedded in the generator’s core (insulation components) and the control system’s “brain” (circuit boards). It provides essential support to ensure wind turbines operate safely, stably, and efficiently for 20–25 years under harsh environmental conditions. With its excellent performance and cost-effectiveness, G10 holds an irreplaceable position in this field.

Leave us a message to get quotation and sample!

If you are interested in our products,, please send us a message and we will contact you as soon as we receive it. Email: info@ztaero.com whatsApp: +8616650273778

Releated News

- 02-10 20262026 Spring Festival Greeting | XUJUE ELECTRICAL

- 02-06 2026G11 Epoxy Sheet for Generator Slot Insulation

- 02-05 2026Fiberglass cloth Prices Continue to Rise | Sheet Product Prices May Be Adjusted

- 02-03 2026Epoxy Pultruded Rod Applications | Electrical Insulation & Structural Support

- 02-02 2026Common Insulation Materials Comparison for High- and Low-Voltage Switchgear

- 01-31 2026Differences Between G11 Epoxy Sheet and EPGC308